Custom Corrugated Roof Panel Roll Forming Equipment for Efficient Roof Solutions

Custom Corrugated Roof Roll Forming Machine A Game Changer in Roofing Solutions

In the modern construction industry, efficiency and precision are paramount, especially when it comes to roofing materials. Among the innovations that have emerged to meet these demands is the custom corrugated roof roll forming machine. This sophisticated piece of machinery is designed to produce high-quality corrugated roofing sheets with remarkable speed and accuracy, making it an indispensable tool for contractors and manufacturers alike.

What is a Corrugated Roof Roll Forming Machine?

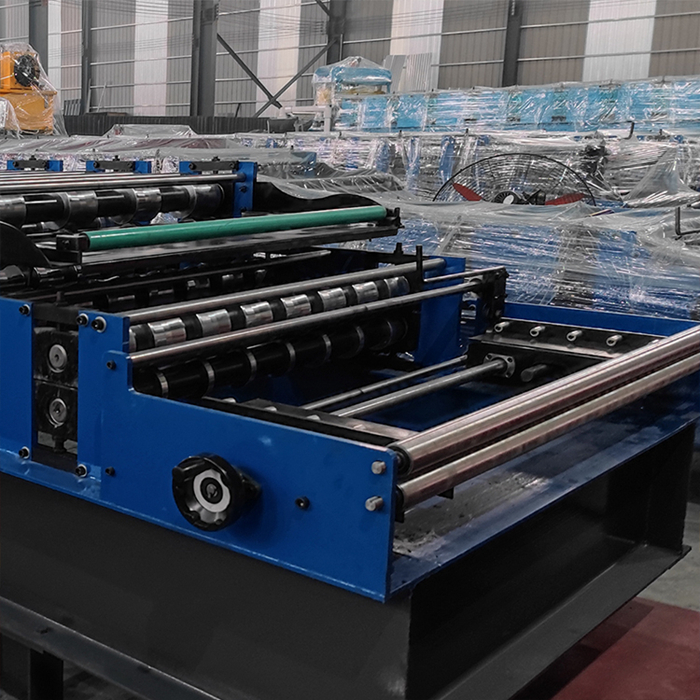

A corrugated roof roll forming machine is a specialized piece of equipment used in the production of corrugated metal sheets. These sheets are widely popular for their strength, durability, and ability to withstand harsh weather conditions. The roll forming process involves feeding a flat metal coil into a series of rollers, which progressively shape the material into the desired profile. The end result is corrugated roofing panels that can be cut to size based on specific requirements.

Benefits of Customization

One of the standout features of modern roll forming machines is their capacity for customization. Customers can tailor their machines according to the specific needs of their projects. This includes adjustments to the sheet profile, thickness, and the dimensions of the final product. Custom solutions enable manufacturers to cater to a variety of demands, whether it’s for residential roofing, commercial buildings, or industrial applications.

For contractors, the ability to produce bespoke roofing sheets means they can provide their clients with unique solutions that stand out in a competitive market. This customization not only supports niche markets but also ensures that the finished product meets local building codes and regulation requirements.

Enhanced Efficiency

Time is money in the construction industry, and the custom corrugated roof roll forming machine addresses this by significantly enhancing production efficiency. The automated processes reduce manual labor and decrease the overall production time. With features like automatic cutting, advanced control systems, and easy-to-use interfaces, operators can achieve high output levels without sacrificing quality.

custom corrugated roof roll forming machine

The machine's ability to produce long runs of roofing sheets without interruption minimizes waste and optimizes resource usage. As a result, both the environmental footprint and operational costs are reduced, providing a win-win situation for manufacturers and the planet.

Precise Quality Control

Quality assurance is another critical advantage of using a custom corrugated roof roll forming machine. Modern machines are equipped with advanced technology that closely monitors the production process. This ensures that every sheet produced meets strict quality standards. Automated adjustments can be made in real-time, reducing the risk of defects and inconsistencies in the final product.

Furthermore, manufacturers can implement various testing methods, such as thickness checks and tensile strength assessments, to ensure that their products are durable and reliable. This level of quality control builds trust with clients and contributes to the overall reputation of the manufacturer in the market.

The Future of Roofing

With the continual advancements in technology, the future of corrugated roofing production looks promising. Innovations such as smart manufacturing, which incorporates IoT and data analytics, are poised to revolutionize the industry even further. Manufacturers will be able to gather real-time data to optimize processes, predict maintenance needs, and even improve designs based on market trends.

Conclusion

In conclusion, a custom corrugated roof roll forming machine is not just a tool; it is a vital asset in the roofing industry. Its ability to provide customized solutions, enhance efficiency, ensure quality control, and adapt to future trends positions it as a game changer in roofing solutions. As demand for quality and sustainability in construction continues to grow, embracing advanced technologies like the roll forming machine will be essential for staying competitive in the ever-evolving marketplace. Investing in such machinery can propel businesses forward, allowing them to deliver superior products that meet the diverse needs of their customers.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025