cheap drywall roll forming machine

Understanding Cheap Drywall Roll Forming Machines

In the construction industry, efficiency and cost-effectiveness are key factors that determine success. One of the critical components in modern construction is drywall, which is widely used for building walls and ceilings. As the demand for drywall increases, manufacturers are continually seeking innovative ways to produce this essential material more economically. One solution that has gained popularity is the use of cheap drywall roll forming machines.

What is a Drywall Roll Forming Machine?

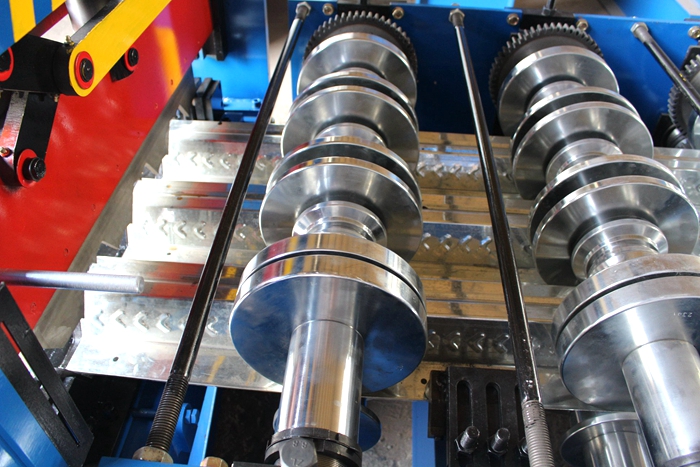

A drywall roll forming machine is a specialized piece of equipment designed to manufacture drywall sheets efficiently. These machines flatten out raw materials, including gypsum and paper, and then form them into specific dimensions. The process of roll forming involves feeding coils of material into the machine, which then shapes the sheets through a series of rollers.

Benefits of Using Cheap Drywall Roll Forming Machines

1. Cost-Effectiveness The most obvious advantage of using cheap drywall roll forming machines is the reduced initial investment required. Many small to medium-sized enterprises may not possess the capital needed to invest in expensive machinery. A more affordable option enables these businesses to enter the market, compete effectively, and provide quality products at lower prices.

2. Increased Production Efficiency Cheap drywall roll forming machines are designed to maximize throughput without compromising on quality. Many of these machines can be operated with minimal manual intervention, allowing manufacturers to increase production rates. This efficiency not only reduces labor costs but also leads to faster turnaround times for clients.

3. Versatility Many budget-friendly drywall roll forming machines come with adjustable settings, enabling manufacturers to produce different drywall types and sizes. This versatility allows businesses to cater to a broader range of customer needs, from residential projects to large-scale commercial constructions.

4. Lower Operational Costs Cheap machines often consume less energy compared to high-end models, translating to lower operational costs. Additionally, with reduced maintenance requirements due to simpler designs, businesses can save money on servicing and repairs.

Challenges of Cheap Drywall Roll Forming Machines

cheap drywall roll forming machine

While there are evident advantages, it's important to acknowledge the challenges associated with using cheaper machinery. Often, cost-cutting can lead to a compromise in quality. Here are a few considerations

1. Quality Control Cheaper machines may not be built with the same attention to detail as higher-end models. This can lead to inconsistency in the final product, which may affect customer satisfaction and brand reputation.

2. Durability and Longevity Budget-friendly options might not have the robustness of more sophisticated machines. This could result in a shorter lifespan and the need for replacement sooner than anticipated, negating any initial savings.

3. Limited Features Many cost-effective machines may lack automated features that enhance precision and quality. For manufacturers aiming to produce specialized drywall, this limitation could be a significant drawback.

4. Technical Support and Training Sometimes, manufacturers of cheap machines may not provide comprehensive technical support or training resources. This could hinder efficient machine operation and maintenance, leading to production delays.

Making the Right Choice

When considering investing in a cheap drywall roll forming machine, it is crucial to weigh the pros and cons carefully. Assess the needs of the business, and consider factors such as production volume, expected product quality, and potential growth. Researching various manufacturers, reading reviews, and possibly visiting factories can provide valuable insights.

Conclusion

Cheap drywall roll forming machines offer a viable solution for small to medium-sized enterprises looking to enter or grow in the drywall market. While they present an opportunity to reduce costs and increase production efficiency, businesses must carefully consider the potential trade-offs in quality and durability. Ultimately, by making informed decisions, companies can leverage these machines to enhance their operations and meet the growing demand for drywall in the construction industry.

-

The Latest Trends in Cut to Length Equipment and MachinesNewsMay.09, 2025

-

Revolutionizing Door Frame Production: The Power of Modern MachinesNewsMay.09, 2025

-

Revolutionary Machines for Roller Shutter and Garage DoorsNewsMay.09, 2025

-

Everything You Need to Know About Gutter Roll Forming MachinesNewsMay.09, 2025

-

Efficiency in Coil Handling with Hydraulic Decoiler MachinesNewsMay.09, 2025

-

Downspout Roll Forming Machines and Their ValueNewsMay.09, 2025

-

Revolutionizing the Door Frame Industry: Key Insights on Roll Forming MachinesNewsApr.18, 2025