custom metal roofing machine cost

Understanding the Cost of Custom Metal Roofing Machines

In the construction and manufacturing industry, metal roofing has become increasingly popular due to its durability, energy efficiency, and aesthetic appeal. With the rise in demand for custom metal roofing solutions, businesses are considering investing in custom metal roofing machines. However, one of the crucial factors that influence this decision is the cost associated with these machines. This article aims to provide a comprehensive overview of the costs involved in acquiring custom metal roofing machines and factors that affect their pricing.

Types of Custom Metal Roofing Machines

Before delving into the costs, it's essential to understand the different types of metal roofing machines available in the market. The primary categories include roll forming machines, shearing machines, and bending machines.

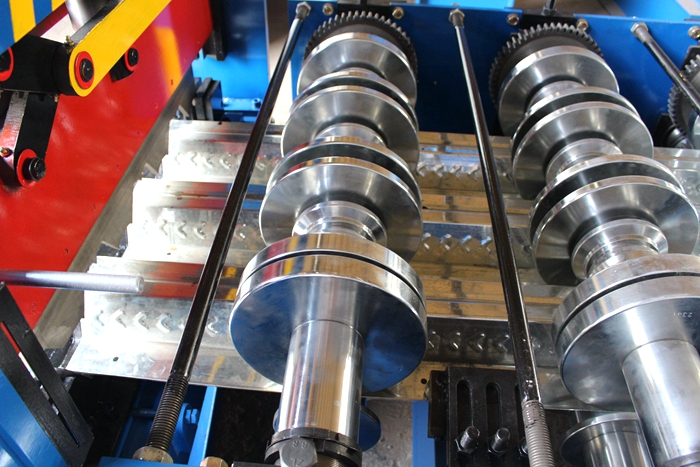

1. Roll Forming Machines These machines are used to create metal roof panels by shaping metal sheets as they pass through a series of rollers. The cost of roll forming machines can vary significantly based on their capabilities, length, and complexity of the design they can produce.

2. Shearing Machines Shearing machines are designed to cut metal sheets into specific lengths and sizes. These machines may be manual or automatic, with automatic models typically costing more.

3. Bending Machines Bending machines are essential for creating the desired angles and profiles in metal roofing. The costs associated with bending machines will depend on the pressure and capacity necessary for the materials used.

Factors Influencing Cost

Several key factors influence the cost of custom metal roofing machines

1. Machine Specifications The specifications of the machine, including the size, production capacity, and technology used, can significantly impact its price. Advanced machines with high production rates and automation features typically come at a higher cost.

2. Material Quality The materials used in manufacturing the machines themselves will also affect the price. High-quality materials may lead to a longer lifespan and better performance but will increase the initial investment.

3. Customization Options Businesses seeking tailored solutions will often incur additional costs. Custom features may include unique designs, specific production capabilities, or specialized software for managing production processes.

custom metal roofing machine cost

4. Brand and Manufacturer The reputation of the manufacturer can play a crucial role in the pricing. Well-established brands may offer more reliable machines, but they often come with a premium price tag compared to lesser-known manufacturers.

5. Location The geographical location of the buyer can also influence the cost. Factors such as shipping, taxes, and local market demand for such machinery can lead to price variations.

Average Cost Estimates

The cost for custom metal roofing machines can vary widely. Here are some general estimates

- Roll Forming Machines Depending on the specifications, prices can range from $20,000 to over $100,000. Basic models may be less expensive, while high-capacity automated systems could exceed this range significantly.

- Shearing Machines The cost of shearing machines generally falls between $10,000 and $50,000, based on whether they are manual or automated.

- Bending Machines Prices for bending machines usually range from $15,000 to $70,000, depending on the functionality and material thickness that the machine can handle.

Additional Considerations

Investing in custom metal roofing machines is not just about the upfront cost. Businesses should also consider ongoing maintenance, operational costs, and the potential return on investment (ROI). A well-functioning machine can significantly reduce labor costs and improve production efficiency, ultimately providing savings that offset initial costs.

Training staff to operate these machines is another important consideration, as this can incur additional expenses. Investing in proper training ensures that the machines are used to their full potential, further enhancing ROI.

Conclusion

The cost of custom metal roofing machines is a multifaceted issue influenced by various factors, including machine type, specifications, and the manufacturer. While the initial investment may seem daunting, companies need to weigh this against the long-term benefits of increased efficiency, reduced labor costs, and the ability to meet customer demands for custom roofing solutions. By carefully considering all aspects involved in this investment, businesses can make informed decisions that align with their operational goals and financial constraints.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025