Drip Edge Production Machines Available for Purchase from Trusted Manufacturer

Drip Edge Machine for Sale Revolutionizing Your Manufacturing Process

In the world of construction and manufacturing, efficiency and quality are paramount. One of the essential components in the roofing industry is the drip edge, a crucial element that prevents water from seeping into the roof's structure. As demand for high-quality roofing solutions continues to rise, the need for reliable production equipment, such as drip edge machines, has never been more pressing. This article explores the benefits of investing in a drip edge machine and why now is the perfect time to consider purchasing one for your factory.

What is a Drip Edge Machine?

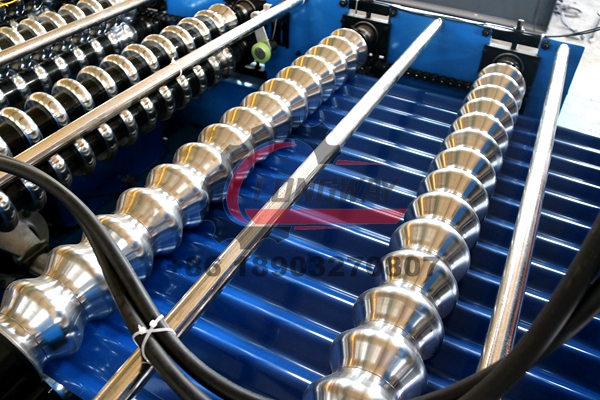

A drip edge machine is a specialized piece of equipment designed for manufacturing drip edges, typically made from metal. These machines allow for precise cutting, bending, and shaping of metal strips into the desired drip edge configurations. The result is a product that provides essential protection to the roof and enhances its overall aesthetic appeal. With the right machine, manufacturers can produce high-quality drip edges in various sizes and profiles to meet the diverse needs of their clients.

The Importance of Drip Edges

Drip edges play a critical role in controlling water runoff from roofs. They are installed at the edges of the roof to direct water away from the fascia and into the gutters. This prevents water damage, reduces the risk of mold and mildew, and prolongs the lifespan of roofing materials. The growing awareness of the significance of proper drainage in roofing has led to an increase in the demand for drip edges, fueling the need for efficient manufacturing processes.

Benefits of Using a Drip Edge Machine

1. Increased Efficiency Modern drip edge machines are designed to streamline the production process. With advanced technology, these machines can handle large volumes of metal with speed and precision. This means manufacturers can meet tight deadlines without compromising quality.

drip edge machine for sale factory

2. Cost-Effectiveness While the initial investment in a drip edge machine might be significant, it pays off in the long run. By producing drip edges in-house, manufacturers can save on labor costs and reduce material waste. Additionally, the ability to customize orders can open new markets and increase profit margins.

3. Quality Control Investing in a drip edge machine allows manufacturers to maintain tighter quality control over their products. By producing drip edges internally, companies can focus on using high-grade materials and adhere to specific quality standards, ultimately leading to a better end product.

4. Flexibility and Customization Every roofing project is unique, and being able to produce drip edges tailored to specific requirements is a considerable advantage. With a reliable drip edge machine, manufacturers can quickly adapt to changing trends and customer preferences, which is invaluable in today’s competitive market.

5. Scalability As businesses grow, so do their production needs. A drip edge machine can easily be integrated into existing operations, allowing for expansion without the need for extensive modifications to the manufacturing process.

Finding the Right Drip Edge Machine for Your Factory

When looking to purchase a drip edge machine, it's essential to consider factors such as production capacity, ease of operation, and after-sales support. Many reputable manufacturers offer a range of models tailored for different production needs, so it's worth investing the time to research options that fit your specific requirements. Additionally, companies that provide warranties and customer support can ensure that your investment is protected.

Conclusion

In summary, a drip edge machine is a vital asset for any manufacturing facility involved in roofing solutions. By improving efficiency, ensuring quality control, and allowing for customization, these machines empower manufacturers to meet the increasing demand for drip edges effectively. As the roofing industry continues to evolve, now is an excellent time to consider adding a drip edge machine to your production line, positioning your factory for success in the competitive marketplace.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025