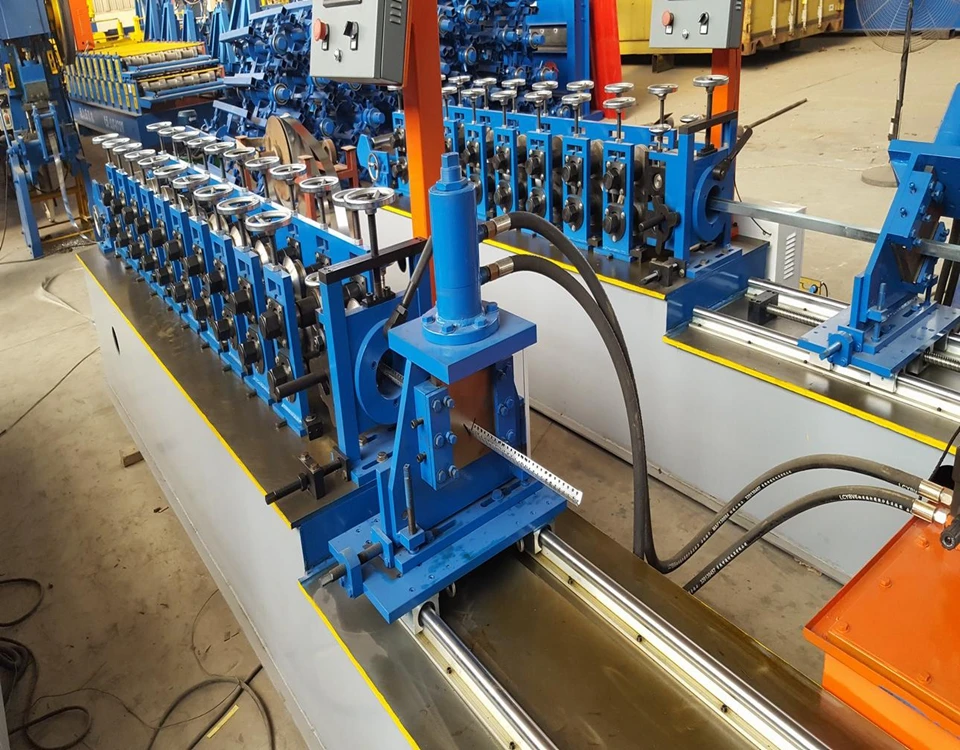

wall angle roll forming machine

Wall Angle Roll Forming Machine An Overview

In the construction and manufacturing sectors, efficiency and precision play pivotal roles in streamlining processes and enhancing productivity. One standout innovation in this domain is the wall angle roll forming machine, a specialized piece of equipment designed for the production of wall angles, which are essential components in various structural applications.

What is a Wall Angle Roll Forming Machine?

A wall angle roll forming machine is engineered to manufacture wall angles from metal sheets, usually galvanized or aluminum. These machines take flat strips of metal and convert them into angular profiles through a series of rollers that shape the material progressively. The result is a durable, lightweight, and precisely dimensioned product that can be used in framing, drywall, and other structural applications.

Key Features

1. Precision Engineering The rolls in the machine are aligned meticulously to ensure that the angles produced are accurate. This precision is vital since even minor deviations can lead to structural issues during installation.

2. Customizable Profiles One of the major advantages of using a roll forming machine is the ability to create custom profiles tailored to specific project requirements. This flexibility allows manufacturers to cater to diverse customer needs.

wall angle roll forming machine

3. High Production Efficiency Wall angle roll forming machines are designed for high-speed operation, which means they can produce large volumes of angles within a short amount of time. This efficiency significantly reduces labor costs and production timelines.

4. Durability and Strength The angles produced are strong and resistant to deformation, which is critical in the construction industry where structural integrity is paramount. The use of high-quality materials enhances the strength and longevity of the final product.

Applications

Wall angles are widely used in both residential and commercial construction projects. They are primarily utilized to create a frame for drywall installations, providing support and a finished edge. Other applications include

- Suspended Ceilings Used as support for ceiling tiles, allowing for easy access to infrastructure above. - Partition Walls Wall angles are essential for creating sturdy and stable partition walls that are common in office environments. - Finishing Edges They provide a clean finish at the edges of walls, enhancing aesthetic appeal.

Conclusion

The wall angle roll forming machine represents a significant advancement in manufacturing technology, marrying efficiency with versatility. By streamlining the production of wall angles, manufacturers can meet the growing demand in the construction industry while ensuring high standards of quality and customization. As construction methods continue to evolve, the importance of such innovative machinery will undoubtedly increase, driving efficiency and performance to new heights. Investing in a wall angle roll forming machine can be a strategic decision for companies aiming to enhance their operational capabilities and product offerings in the competitive construction market.

-

Optimizing Your Production with CZ Purlin MachinesNewsMay.19, 2025

-

Maximizing Efficiency with C and U Channel Roll Forming MachinesNewsMay.19, 2025

-

Investing in Z Purlin MachinesNewsMay.19, 2025

-

Efficient Solutions with Metal Stud and Track Roll Forming MachinesNewsMay.19, 2025

-

Choosing the Best C Purlin MachinesNewsMay.19, 2025

-

Boost Your Production with Wall Angle Roll Forming MachinesNewsMay.19, 2025

-

Understanding Steel Coil Cutting Machines and Their ImportanceNewsMay.16, 2025