Investing in Z Purlin Machines

The Z 도리 성형 기계 is an essential tool for manufacturers looking to produce Z-shaped purlins with high precision and efficiency. This machine is designed to transform flat metal sheets into Z-shaped profiles, commonly used in construction for support structures, framing, and roofing systems. The Z 도리 성형 기계 allows for smooth, continuous production, ensuring that the purlins produced are uniform in size, shape, and strength. Its automated features significantly reduce labor costs and production time, making it a cost-effective investment for businesses in the construction and metalworking industries. By incorporating a Z 도리 성형 기계 into your operations, you can increase your production capacity while maintaining high standards of quality and consistency. This machine is highly versatile, capable of handling different materials, such as steel, aluminum, and galvanized steel, making it a valuable addition to any metal fabrication facility.

Z Purlin Machine: Maximizing Efficiency in Production

A Z purlin machine is the core equipment needed to manufacture Z purlins quickly and accurately. Whether you are producing purlins for residential, commercial, or industrial projects, the Z purlin machine streamlines the production process, reducing both time and costs. These machines are highly efficient, designed with automation features that allow for faster setup times and high-speed production. The Z purlin machine also minimizes material waste by cutting the purlins to precise lengths, ensuring that each product is consistent and of superior quality. By automating the roll-forming process, businesses can achieve greater production volumes with fewer manual interventions, resulting in reduced labor costs and increased profitability. A high-quality Z purlin machine will enhance the overall efficiency of any manufacturing operation, providing long-term value for businesses in the construction and metal industries.

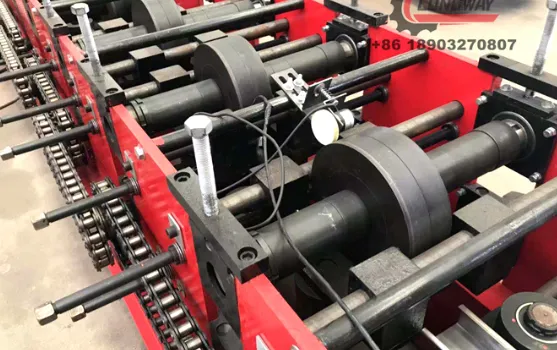

Z Purlin Roll Forming Machine: Key Features and Advantages

The Z purlin roll forming machine is a critical piece of equipment for fabricating Z-shaped purlins used in structural applications. This advanced machine utilizes a series of rollers to progressively form metal sheets into the desired Z-shaped profile. One of the key advantages of the Z purlin roll forming machine is its ability to handle various types of metals, including steel, galvanized steel, and aluminum, while maintaining high precision and uniformity in the final product. The machine’s automation features further enhance its productivity, reducing the need for manual intervention and increasing production output. With a Z purlin roll forming machine, businesses can achieve greater efficiency in their production process while ensuring that each purlin meets strict quality standards. This machine is ideal for high-volume production runs and is designed to deliver consistent, high-quality results, making it a valuable investment for any manufacturer looking to enhance their operations.

Z Purlin Making Machine: Versatile and Cost-Effective Solution

The Z purlin making machine is a versatile tool designed to produce high-quality Z-shaped purlins in an efficient and cost-effective manner. Ideal for large-scale production, the Z purlin making machine combines high-speed operation with precision, making it perfect for businesses that need to manufacture large quantities of purlins quickly. The machine operates by feeding metal coils into a set of rollers that gradually form the material into the desired Z profile. One of the major benefits of the Z purlin making machine is its flexibility – it can produce purlins of various sizes and thicknesses to meet the specific requirements of different projects. Additionally, the machine's automation features reduce labor costs and production time, making it an excellent investment for businesses looking to boost their manufacturing capabilities. The Z purlin making machine is highly durable and designed to withstand the demands of high-volume production, ensuring reliable performance for years to come.

Z Purlin Machines and Their Role in the Construction Industry

Z purlin machines, including the Z 도리 성형 기계, Z purlin roll forming machine, and Z purlin making machine, play a crucial role in the construction industry by providing a fast, reliable method for producing structural purlins. These machines are integral in manufacturing the support components used in building frameworks, roofs, and other structural systems. With the growing demand for durable, cost-effective construction materials, investing in a Z purlin machine is an essential step for businesses that wish to remain competitive in the market. These machines offer significant advantages, such as increased production speed, reduced material waste, and higher product consistency. Whether for residential or commercial projects, the use of Z purlin machines helps meet the growing demand for high-quality building materials while improving operational efficiency and profitability.

Z Purlin Machines FAQs

What materials can a Z purlin machine process?

A Z purlin machine can process various materials, including steel, galvanized steel, aluminum, and other metals typically used in construction and structural framing. This versatility makes the machine suitable for different types of projects.

How fast can a Z purlin roll forming machine produce purlins?

The production speed of a Z purlin roll forming machine varies depending on the model and the complexity of the purlin design. However, modern machines are designed for high-speed operation and can produce large quantities of purlins quickly, often producing several meters per minute.

What is the cost range of a Z purlin making machine?

The cost of a Z purlin making machine can range from $20,000 to $60,000, depending on the machine’s features, production capacity, and level of automation. Higher-end models with advanced features may cost more, but they offer increased efficiency and long-term savings.

How can I maintain a Z purlin machine?

To maintain a Z purlin machine, regular cleaning, lubrication, and inspection are essential. Following the manufacturer's maintenance schedule and ensuring that the machine is regularly serviced will help extend its lifespan and maintain its efficiency.

Can a Z purlin machine produce different sizes of purlins?

Yes, a Z purlin machine is typically adjustable and can produce different sizes of Z-shaped purlins. Many machines feature customizable settings to adjust the width, thickness, and length of the purlins according to customer specifications.

-

Corrugated iron roofing sheet making machine with CE, Auto소식Nov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy Duty소식Nov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNC소식Nov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, Precise소식Nov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, Precise소식Nov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & Durable소식Nov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CE소식Nov.11, 2025