Understanding the Process and Applications of Slitting Line Technology in Manufacturing

Understanding the Slitting Line in Steel Processing

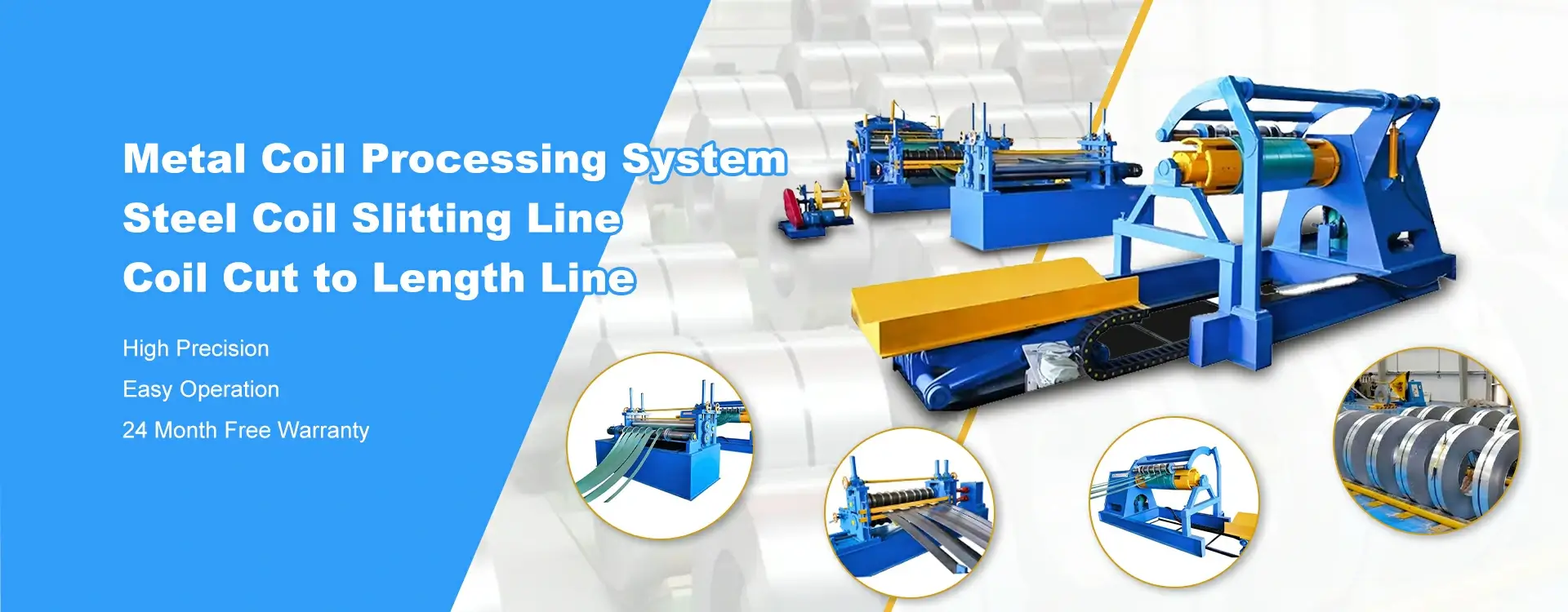

The slitting line is a critical component in the steel processing industry, designed to convert wide coils of steel into narrower strips. This equipment plays a vital role in the manufacturing process, catering to various industries such as automotive, construction, and appliances. With the demand for precision and efficiency in metal processing, the slitting line has evolved into a sophisticated system that ensures optimal performance and high-quality outputs.

A typical slitting line consists of several integrated components, including unwinders, slitting tools, tensioning systems, and rewinders. The process begins with the uncoiling of a large roll of steel, often referred to as a parent coil. Proper unwinding is crucial because it sets the stage for the subsequent slitting process. The steel is then fed through a series of rotary knives that slice the wide coil into narrower strips according to specified widths. These knives can be adjusted to produce strips of various thicknesses, making the slitting line versatile for different applications.

Tension control is another essential factor in the slitting process. Maintaining the appropriate tension ensures that the strips are cut accurately and that there is minimal risk of deformation during processing. Advanced slitting lines incorporate tensioning systems that monitor and adjust the tension dynamically throughout the operation. This capability is particularly beneficial for handling high-strength materials that require precise processing to meet quality standards.

slitting line

Once the steel strips have been sliced to the desired width, they are wound into coils by the rewinder section of the line. The finished coils can vary in size and weight, depending on customer requirements. It is not uncommon for slitting lines to be equipped with automatic systems that facilitate the recoiling process, ensuring that the final product is neatly packaged for shipment.

In terms of technological advancements, modern slitting lines often feature software automation that enables real-time monitoring and adjustments during the operation. This automation not only increases processing speeds but also enhances the overall quality of the product by reducing potential errors and waste.

Quality control is a paramount aspect of slitting line operations. Many facilities implement stringent inspection protocols to verify that the produced steel strips meet industry standards. This can include measuring strip width, thickness, and surface quality, ensuring that the end product is suitable for its intended application.

In conclusion, the slitting line is an indispensable piece of machinery in the steel processing industry. By efficiently converting wide coils into precise strips, slitting lines enable manufacturers to meet the diverse needs of their customers. As technology continues to advance, the efficiency and capabilities of slitting lines are expected to improve, further enhancing their role in modern manufacturing processes.

-

Optimizing Your Production with CZ Purlin MachinesNewsMay.19, 2025

-

Maximizing Efficiency with C and U Channel Roll Forming MachinesNewsMay.19, 2025

-

Investing in Z Purlin MachinesNewsMay.19, 2025

-

Efficient Solutions with Metal Stud and Track Roll Forming MachinesNewsMay.19, 2025

-

Choosing the Best C Purlin MachinesNewsMay.19, 2025

-

Boost Your Production with Wall Angle Roll Forming MachinesNewsMay.19, 2025

-

Understanding Steel Coil Cutting Machines and Their ImportanceNewsMay.16, 2025