1월 . 26, 2025 06:19

Back to list

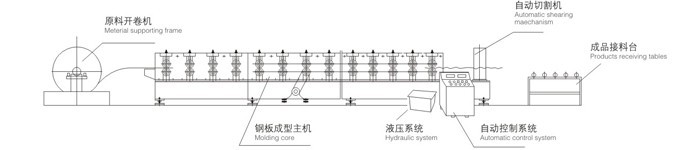

corrugated roofing sheet machine

When considering the acquisition of a roofing sheet manufacturing machine, understanding the intricacies of pricing is essential for any business aiming to optimize its production efficiency and cost-effectiveness. This comprehensive guide provides insights into the factors affecting pricing, ensuring informed decisions for your manufacturing needs.

5. Production Capacity and Speed Another crucial factor is the machine's production capacity. Machines that can produce larger quantities of roofing sheets at a faster pace are generally more expensive. However, if your business requires high-volume production, the investment can lead to substantial gains in terms of output and efficiency. 6. Energy Efficiency and Environmental Considerations Modern roofing sheet machines that are energy-efficient not only help in reducing operational costs but also align with global sustainability standards. While these machines may carry a premium, their long-term impact on reducing energy bills and carbon footprint can be beneficial both financially and reputationally. 7. Geographic Location and Shipping Costs The location of your operations relative to the manufacturing source can significantly impact the final cost of the machine. Shipping expenses, along with any applicable import duties or taxes, should be considered when budgeting for new equipment. 8. Customization and Additional Features Lastly, the need for customizations or additional features can influence machine pricing. Whether you require specific functionalities or design modifications, these bespoke elements are tailored at an additional cost but ensure the equipment meets your precise operational requirements. In conclusion, while the price of a roofing sheet manufacturing machine can vary based on numerous factors, it is crucial to weigh these variables against your specific business needs and long-term production goals. Carefully evaluating machine type, automation level, material quality, and other outlined factors will aid in making a well-informed purchase that optimizes both your production capacity and financial viability. Investing wisely not only secures operational effectiveness but also strengthens your business's competitive position in the market. By approaching this investment with a detailed understanding and strategic planning, businesses can ensure maximum value and longevity from their roofing sheet manufacturing machinery, aligning both with industry standards and their unique performance objectives.

5. Production Capacity and Speed Another crucial factor is the machine's production capacity. Machines that can produce larger quantities of roofing sheets at a faster pace are generally more expensive. However, if your business requires high-volume production, the investment can lead to substantial gains in terms of output and efficiency. 6. Energy Efficiency and Environmental Considerations Modern roofing sheet machines that are energy-efficient not only help in reducing operational costs but also align with global sustainability standards. While these machines may carry a premium, their long-term impact on reducing energy bills and carbon footprint can be beneficial both financially and reputationally. 7. Geographic Location and Shipping Costs The location of your operations relative to the manufacturing source can significantly impact the final cost of the machine. Shipping expenses, along with any applicable import duties or taxes, should be considered when budgeting for new equipment. 8. Customization and Additional Features Lastly, the need for customizations or additional features can influence machine pricing. Whether you require specific functionalities or design modifications, these bespoke elements are tailored at an additional cost but ensure the equipment meets your precise operational requirements. In conclusion, while the price of a roofing sheet manufacturing machine can vary based on numerous factors, it is crucial to weigh these variables against your specific business needs and long-term production goals. Carefully evaluating machine type, automation level, material quality, and other outlined factors will aid in making a well-informed purchase that optimizes both your production capacity and financial viability. Investing wisely not only secures operational effectiveness but also strengthens your business's competitive position in the market. By approaching this investment with a detailed understanding and strategic planning, businesses can ensure maximum value and longevity from their roofing sheet manufacturing machinery, aligning both with industry standards and their unique performance objectives.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products