3월 . 07, 2025 01:32

Back to list

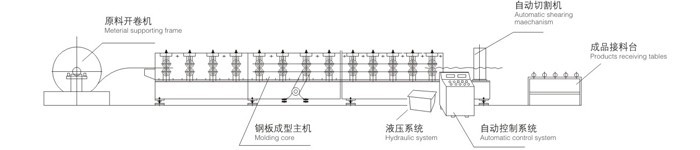

roll metal forming machine

Navigating the realm of roll metal forming machines, one steps into a world where engineering mastery meets industrial necessity. Roll metal forming, an artful yet mechanical process, is the cornerstone of modern manufacturing, bridging the gap between conceptual design and physical structure with unmatched precision and efficiency.

Authoritativeness in the roll forming sector is not merely about size or market reach; it’s about pioneering advancements and setting industry standards. Leading manufacturers of roll metal forming machines are often those who push the boundaries of what's possible. By developing patented processes and implementing state-of-the-art technology, these companies establish benchmarks that others follow. Their commitment to innovation, backed by rigorous testing and quality assurance, solidifies their standing as industry pacesetters—trusted by global industries to drive progress and meet evolving construction and manufacturing challenges. Trustworthiness, the cornerstone of any productive business relationship, is earned through proven reliability and consistent performance. Manufacturers of roll metal forming machines demonstrate this by offering robust after-sales service, comprehensive warranties, and customer-centric solutions. This builds a reputation for dependability that is indispensable, especially in industries where downtime translates to significant financial losses. Furthermore, these manufacturers often collaborate closely with clients, customizing their machines to fit unique operational requirements and ensuring seamless integration into existing production lines. Integrating roll metal forming machines into production not only optimizes manufacturing efficiency but also aligns with current sustainable practices. By reducing material waste and energy consumption, these machines contribute to eco-friendly operations, reinforcing the industry's commitment to environmental stewardship. This alignment with sustainable manufacturing practices enhances the sector’s credibility, meeting the increasing demand for greener production solutions. In conclusion, roll metal forming machines exemplify a symbiotic blend of experience, expertise, authority, and trust. They serve as indispensable assets in constructing the backbone of various industrial sectors, from automotive and aerospace to construction and beyond. By investing in these machines, manufacturers are not just enhancing their production capabilities but also aligning with a legacy of innovation and a future of sustainable growth. Harnessing the power of roll metal forming machines is, therefore, an astute decision for any industry leader aiming to maintain competitive advantage while pushing the envelope of what manufacturing can achieve.

Authoritativeness in the roll forming sector is not merely about size or market reach; it’s about pioneering advancements and setting industry standards. Leading manufacturers of roll metal forming machines are often those who push the boundaries of what's possible. By developing patented processes and implementing state-of-the-art technology, these companies establish benchmarks that others follow. Their commitment to innovation, backed by rigorous testing and quality assurance, solidifies their standing as industry pacesetters—trusted by global industries to drive progress and meet evolving construction and manufacturing challenges. Trustworthiness, the cornerstone of any productive business relationship, is earned through proven reliability and consistent performance. Manufacturers of roll metal forming machines demonstrate this by offering robust after-sales service, comprehensive warranties, and customer-centric solutions. This builds a reputation for dependability that is indispensable, especially in industries where downtime translates to significant financial losses. Furthermore, these manufacturers often collaborate closely with clients, customizing their machines to fit unique operational requirements and ensuring seamless integration into existing production lines. Integrating roll metal forming machines into production not only optimizes manufacturing efficiency but also aligns with current sustainable practices. By reducing material waste and energy consumption, these machines contribute to eco-friendly operations, reinforcing the industry's commitment to environmental stewardship. This alignment with sustainable manufacturing practices enhances the sector’s credibility, meeting the increasing demand for greener production solutions. In conclusion, roll metal forming machines exemplify a symbiotic blend of experience, expertise, authority, and trust. They serve as indispensable assets in constructing the backbone of various industrial sectors, from automotive and aerospace to construction and beyond. By investing in these machines, manufacturers are not just enhancing their production capabilities but also aligning with a legacy of innovation and a future of sustainable growth. Harnessing the power of roll metal forming machines is, therefore, an astute decision for any industry leader aiming to maintain competitive advantage while pushing the envelope of what manufacturing can achieve.

Latest news

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

Related Products