Roll Former for Volcometal Parante Companies | Precision Metal Forming Solutions

Roll Formers A Key Asset for Volcometal Parante Companies

In the rapidly advancing world of manufacturing, the adoption of innovative technologies has become crucial for companies striving to maintain a competitive edge. Roll forming, a highly efficient production method primarily used in the fabrication of metal products, has emerged as an essential process for various industries, including the Volcometal Parante sector. This article explores the significance of roll formers within this niche and their direct impact on manufacturing efficiency.

Roll forming machines work by continuously shaping metal sheets into desired profiles as they are fed through a series of rollers. This technique offers numerous advantages, making it an attractive choice for companies that deal with metal components. For Volcometal Parante companies, which often require high precision and durability in metal products, the roll forming process is indispensable.

One of the primary benefits of using roll formers is the consistency in the quality of finished products. The process allows for precise control over the dimensions of the metal components, ensuring that they meet stringent industry standards. This is particularly important for Volcometal Parante companies that produce components for construction and automotive applications, where deviations in tolerances can lead to significant issues down the line.

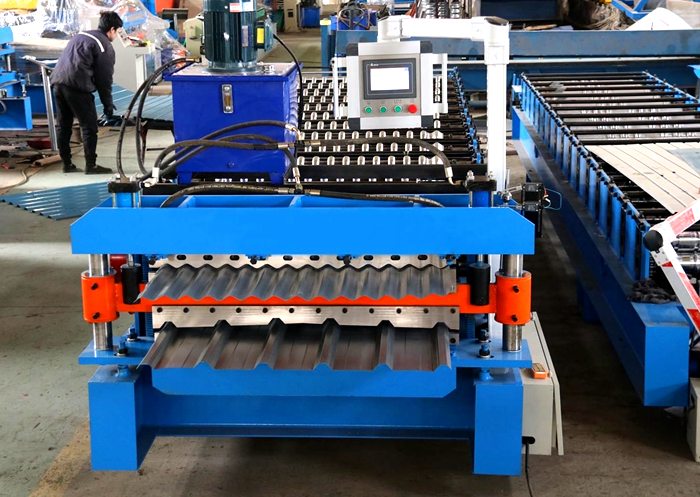

roll former for volcometal parante companies

Additionally, roll forming is known for its efficiency and cost-effectiveness. Unlike traditional metalworking processes like stamping or machining, roll forming produces minimal waste material, making it an environmentally friendly option. The continuous nature of the process allows for high-volume production runs, which further reduces the cost per unit. For Volcometal Parante companies looking to optimize their production capabilities while minimizing operational expenses, integrating roll formers into their manufacturing lines can result in substantial economic benefits.

Moreover, the roll forming process is versatile and can accommodate a wide range of materials, including steel, aluminum, and specialized alloys. This flexibility enables Volcometal Parante companies to explore different design possibilities and create customized solutions to meet specific client needs. As the demand for unique metal profiles grows, having advanced roll forming capabilities can be a game-changer.

Another important consideration is the integration of modern technology into roll formers. With advancements in automation and control systems, companies can now achieve greater monitoring and control over their production processes. This leads to improved production planning, reduced downtime, and enhanced quality assurance. For Volcometal Parante companies aiming to stay ahead in a competitive market, embracing such technological innovations is essential.

In conclusion, roll formers represent a vital component of the manufacturing landscape for Volcometal Parante companies. Their ability to produce high-quality, customized metal profiles efficiently and cost-effectively makes them an asset that cannot be overlooked. As the industry continues to evolve and the demand for precision-engineered products rises, the importance of roll forming will only become more pronounced. Embracing this technology will undoubtedly enable Volcometal Parante companies to thrive in an increasingly competitive world.

-

Optimizing Your Production with CZ Purlin MachinesNewsMay.19, 2025

-

Maximizing Efficiency with C and U Channel Roll Forming MachinesNewsMay.19, 2025

-

Investing in Z Purlin MachinesNewsMay.19, 2025

-

Efficient Solutions with Metal Stud and Track Roll Forming MachinesNewsMay.19, 2025

-

Choosing the Best C Purlin MachinesNewsMay.19, 2025

-

Boost Your Production with Wall Angle Roll Forming MachinesNewsMay.19, 2025

-

Understanding Steel Coil Cutting Machines and Their ImportanceNewsMay.16, 2025