Top Metal Roll Forming Manufacturers and Their Solutions for Your Projects

The Role of Metal Roll Forming Companies in Modern Manufacturing

Metal roll forming is a crucial process in the manufacturing industry, enabling the production of various metal products with high precision and efficiency. Metal roll forming companies play a significant role in delivering tailored solutions to meet the diverse needs of various sectors, including construction, automotive, electronics, and more. In this article, we will explore the significance of these companies, the technology behind metal roll forming, and the applications of the products they create.

What is Metal Roll Forming?

Metal roll forming is a continuous process used to shape metal into specific profiles by passing it through a series of rollers. Flat metal sheets, typically made from steel, aluminum, or other alloys, are continuously fed into the machine, where they are gradually shaped as they pass through multiple sets of rollers. This method is preferred for creating consistent and repeatable shapes, especially for long lengths of material.

One of the main advantages of metal roll forming is its efficiency. Unlike other fabrication methods, it generates minimal waste, as the metal is shaped without being cut. Additionally, roll forming allows for the production of complex profiles, providing manufacturers with the flexibility to design components that meet exact specifications for various applications.

Technologies in Metal Roll Forming

Metal roll forming companies utilize advanced technologies to enhance the efficiency and precision of their processes. Computer-aided design (CAD) software is commonly used to create detailed designs and simulate the roll forming process before it begins. This allows engineers to visualize potential issues and optimize the design for production.

Moreover, many companies employ automation and robotics to streamline the manufacturing process. Automated systems can improve production speed, reduce labor costs, and enhance consistency in the final products. Integrating advanced technologies, such as Industry 4.0 practices, is becoming increasingly common within metal roll forming companies, allowing for real-time monitoring and data analysis to optimize efficiency.

Applications of Metal Roll Forming Products

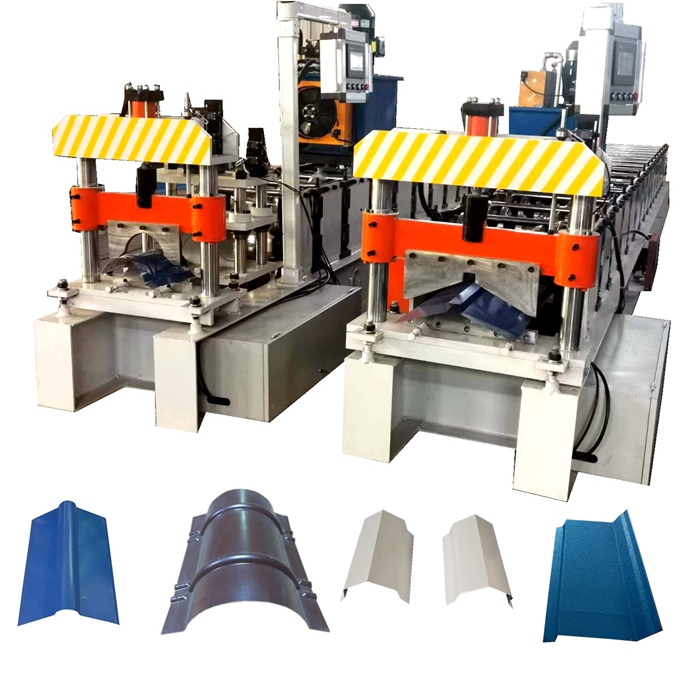

The products manufactured by metal roll forming companies serve a wide variety of industries. In the construction sector, roll-formed components are frequently used in roofing, siding, support frames, and structural parts. These products are valued for their strength, durability, and resistance to corrosion, making them ideal for various environmental conditions.

In the automotive industry, metal roll forming is used to create components such as chassis, running boards, and various brackets

. The ability to produce lightweight yet sturdy components is critical in enhancing fuel efficiency and performance in modern vehicles.metal roll forming companies companies

In the electronics sector, metals produced through roll forming are used for enclosures, heat sinks, and other essential components. The precision offered by roll forming allows for the creation of parts that accommodate intricate designs and necessary functionalities.

Choosing the Right Metal Roll Forming Company

Selecting the right metal roll forming company is essential for ensuring the success of a manufacturing project. Companies should consider several factors when making their choice

1. Experience and Expertise Companies with a proven track record and expertise in specific industries are more likely to understand the unique challenges and requirements of different projects.

2. Customization Capabilities The ability to design and manufacture custom profiles according to the client’s specifications is crucial for achieving the desired results.

3. Quality Assurance It’s important to assess the quality control measures a company has in place. ISO certifications and quality management systems are indicative of a commitment to excellence.

4. Technology and Equipment A company that invests in advanced technologies and modern equipment can generally offer higher precision and efficiency in the manufacturing process.

5. Customer Service A responsive and attentive customer service team can make a significant difference in communication and collaboration throughout the project.

Conclusion

Metal roll forming companies play an integral role in modern manufacturing by providing high-quality, efficient, and customizable metal products. As industries continue to evolve, the demand for innovative solutions will only increase, making the expertise of these companies essential. By leveraging advanced technologies and maintaining a focus on quality, metal roll forming companies will continue to contribute significantly to the industrial landscape. With their ability to adapt to changing market demands, they are well-positioned to support the growth of various sectors in the years to come.

-

Optimizing Your Production with CZ Purlin MachinesNewsMay.19, 2025

-

Maximizing Efficiency with C and U Channel Roll Forming MachinesNewsMay.19, 2025

-

Investing in Z Purlin MachinesNewsMay.19, 2025

-

Efficient Solutions with Metal Stud and Track Roll Forming MachinesNewsMay.19, 2025

-

Choosing the Best C Purlin MachinesNewsMay.19, 2025

-

Boost Your Production with Wall Angle Roll Forming MachinesNewsMay.19, 2025

-

Understanding Steel Coil Cutting Machines and Their ImportanceNewsMay.16, 2025