2월 . 17, 2025 23:07

Back to list

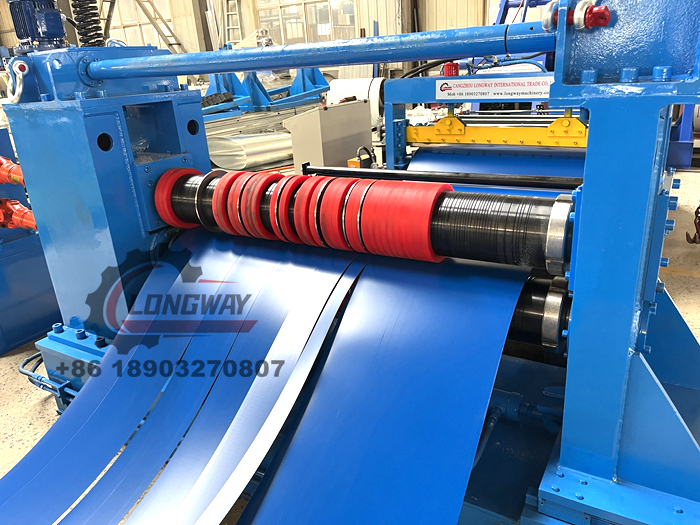

galvanized roof sheet roll forming machine

In the world of manufacturing and construction, the demand for efficient and durable roofing solutions is ever-increasing. The galvanized roof sheet roll forming machine stands out as a pivotal element in this sector, offering an unparalleled blend of quality production, cost-efficiency, and technological advancement. This state-of-the-art equipment is redefining how roofing materials are produced, ensuring that builders and developers have access to high-quality, reliable roofing options that can withstand various environmental challenges.

From an authority standpoint, leveraging a galvanized roof sheet roll forming machine sets a company apart in the highly competitive roofing materials industry. Companies that utilize such advanced machinery are often perceived as leaders in the innovation of durable building materials. Their commitment to quality and efficiency speaks volumes about their ability to meet the large-scale demands of modern construction projects. Successfully operating these machines requires trained technicians, whose expertise guarantees that the entire process, from raw material handling to finished product inspection, is conducted with precision and care. The trustworthiness of a product is often reflected in its performance in real-world conditions. Galvanized roof sheets produced using roll forming machines have been rigorously tested to ensure they can endure temperature fluctuations, high winds, and even corrosive environments. Builders and architects can rely on these materials to provide outstanding structural integrity and longevity, making them a favored choice for commercial and residential projects alike. In conclusion, the galvanized roof sheet roll forming machine is not merely a piece of equipment but a pivotal asset in the production of high-quality roofing materials. Its design and operational efficiencies reflect both current technological advancements and a steadfast commitment to quality and durability. For manufacturers and builders alike, these machines represent a strategic investment that ensures consistent product output, meets the high standards demanded by the market, and bolsters a company’s reputation for expertise and reliability in the construction industry.

From an authority standpoint, leveraging a galvanized roof sheet roll forming machine sets a company apart in the highly competitive roofing materials industry. Companies that utilize such advanced machinery are often perceived as leaders in the innovation of durable building materials. Their commitment to quality and efficiency speaks volumes about their ability to meet the large-scale demands of modern construction projects. Successfully operating these machines requires trained technicians, whose expertise guarantees that the entire process, from raw material handling to finished product inspection, is conducted with precision and care. The trustworthiness of a product is often reflected in its performance in real-world conditions. Galvanized roof sheets produced using roll forming machines have been rigorously tested to ensure they can endure temperature fluctuations, high winds, and even corrosive environments. Builders and architects can rely on these materials to provide outstanding structural integrity and longevity, making them a favored choice for commercial and residential projects alike. In conclusion, the galvanized roof sheet roll forming machine is not merely a piece of equipment but a pivotal asset in the production of high-quality roofing materials. Its design and operational efficiencies reflect both current technological advancements and a steadfast commitment to quality and durability. For manufacturers and builders alike, these machines represent a strategic investment that ensures consistent product output, meets the high standards demanded by the market, and bolsters a company’s reputation for expertise and reliability in the construction industry.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products