2월 . 17, 2025 22:08

Back to list

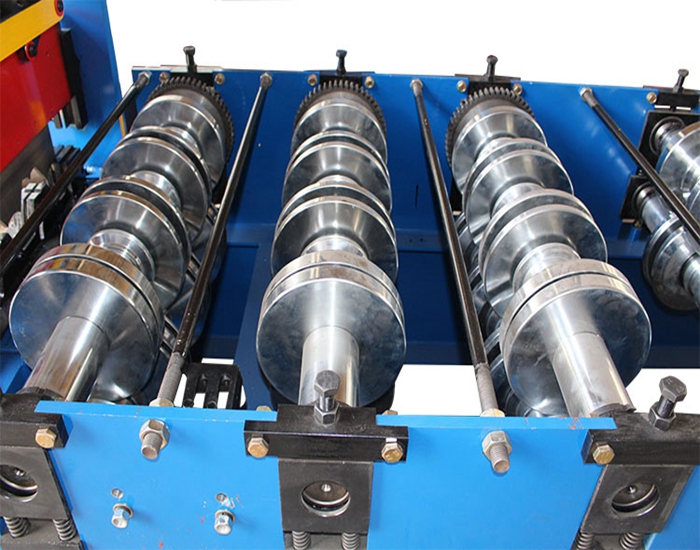

galvanized panel roll forming machine

A galvanized panel roll forming machine stands as a pinnacle of innovation in the metal fabrication industry, offering an array of possibilities for manufacturers seeking durable, sturdy, and corrosion-resistant panels. As industries evolve, the demand for high-quality metal panels that promise longevity without compromising on functionality becomes imperative. This machine emerges as an essential tool, delivering efficiency and precision while ensuring the highest standards of quality and performance.

The roll forming machine opens new avenues for customizable solutions, catering to specific industrial needs. With adjustable settings, manufacturers can produce a variety of profiles and sizes, offering flexibility and versatility in product design. The precision of this machine allows for minimal errors during production, reducing the need for subsequent adjustments and modifications. Authoritativeness is reinforced by endorsements from industry leaders who have incorporated this technology into their operations. The success stories of businesses that have experienced increased efficiency, reduced costs, and enhanced product quality underscore the reliability and necessity of galvanized panel roll forming machines. Testimonials highlight how these machines have transformed production lines, emphasizing their critical role in achieving sustainable business growth. Investing in a galvanized panel roll forming machine represents a commitment to innovative and efficient manufacturing solutions. It's an investment not just in advanced technology, but also in ensuring that the products manufactured meet the highest standards of quality and durability demanded by today's stringent market conditions. Companies that prioritize the adoption of such technology are positioned as leaders in their field, setting benchmarks in manufacturing excellence and product reliability. In conclusion, the galvanized panel roll forming machine embodies a harmonious blend of technology, expertise, and durability. As industries strive for more efficient production methods and higher-quality products, this machine emerges as an irreplaceable asset, offering unmatched precision, reliability, and efficiency. Its contribution to the future of metal fabrication is undeniable, marking a transformative shift in how manufacturers approach the challenges of modern production demands.

The roll forming machine opens new avenues for customizable solutions, catering to specific industrial needs. With adjustable settings, manufacturers can produce a variety of profiles and sizes, offering flexibility and versatility in product design. The precision of this machine allows for minimal errors during production, reducing the need for subsequent adjustments and modifications. Authoritativeness is reinforced by endorsements from industry leaders who have incorporated this technology into their operations. The success stories of businesses that have experienced increased efficiency, reduced costs, and enhanced product quality underscore the reliability and necessity of galvanized panel roll forming machines. Testimonials highlight how these machines have transformed production lines, emphasizing their critical role in achieving sustainable business growth. Investing in a galvanized panel roll forming machine represents a commitment to innovative and efficient manufacturing solutions. It's an investment not just in advanced technology, but also in ensuring that the products manufactured meet the highest standards of quality and durability demanded by today's stringent market conditions. Companies that prioritize the adoption of such technology are positioned as leaders in their field, setting benchmarks in manufacturing excellence and product reliability. In conclusion, the galvanized panel roll forming machine embodies a harmonious blend of technology, expertise, and durability. As industries strive for more efficient production methods and higher-quality products, this machine emerges as an irreplaceable asset, offering unmatched precision, reliability, and efficiency. Its contribution to the future of metal fabrication is undeniable, marking a transformative shift in how manufacturers approach the challenges of modern production demands.

Latest news

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

Related Products