tile roll forming machine manufacturer

The Evolution and Significance of Tile Roll Forming Machine Manufacturers

In the modern era of construction and manufacturing, the demand for efficient and cost-effective building materials has surged. Among these, metal roofing and wall tiles are gaining immense popularity for their durability, aesthetic appeal, and environmental benefits. The production of these tiles has evolved significantly, thanks largely to advanced technologies like roll forming machines. Tile roll forming machine manufacturers play a crucial role in this industry, providing the equipment necessary for producing high-quality metal tiles at scale.

Understanding Tile Roll Forming Machines

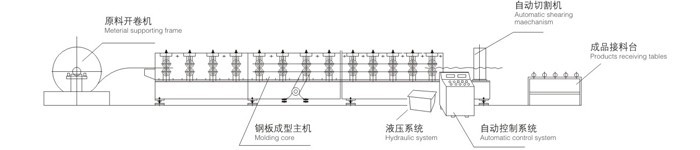

Tile roll forming machines are specialized tools designed to manufacture metal sheets into various tile profiles. These machines operate by feeding flat metal sheets through a series of rollers that progressively shape the metal into the desired form. The process typically involves the following steps

1. Material Preparation High-quality steel coils, often pre-painted or coated for added durability and aesthetics, are fed into the machine. 2. Roll Forming As the steel passes through the rollers, it undergoes bending and shaping to create the final tile profile. This continuous process allows for high production rates and minimal waste.

3. Cutting Once the desired length is achieved, the machine cuts the profiles to specified lengths, ready for shipment or installation.

Benefits of Using Tile Roll Forming Machines

Tile roll forming machines provide a host of advantages that make them essential for manufacturers in the construction industry

- Efficiency The automated nature of these machines significantly reduces production times. With high-speed rollers and precise cutting mechanisms, manufacturers can produce large quantities of tiles in a fraction of the time it takes with traditional methods.

- Customization Manufacturers can create customized tile profiles tailored to specific project requirements. This flexibility allows for innovation in design, catering to various architectural styles and preferences.

tile roll forming machine manufacturer

- Cost-Effectiveness While the initial investment in a roll forming machine may be substantial, the long-term benefits include reduced labor costs, minimized waste, and lower material costs due to efficient processing

.- Consistent Quality Advanced technology in tile roll forming machines ensures a high level of precision and uniformity. This consistency is crucial for maintaining quality standards in construction projects.

The Role of Manufacturers

Tile roll forming machine manufacturers are pivotal in advancing the technology and capabilities of these machines. They invest in research and development to enhance the efficiency, durability, and performance of their products. Here are some key responsibilities of these manufacturers

- Innovation Manufacturers continuously seek innovative designs and technologies to improve the functionality of roll forming machines. This includes developing new profiles, enhancing automation features, and incorporating smart technology for operational monitoring and control.

- Customer Support A significant aspect of a manufacturer’s role is providing support to customers. This includes installation, maintenance, and training on how to operate the machinery effectively. Strong after-sales services can make a significant difference in customer satisfaction and loyalty.

- Sustainability Initiatives As environmental awareness grows, many manufacturers are optimizing their machines to be more energy-efficient. This not only reduces the carbon footprint of the production process but also aligns with the increasing demand for sustainable construction practices.

Conclusion

The emergence of tile roll forming machine manufacturers has transformed the landscape of metal tile production. By leveraging technology, these manufacturers are able to provide solutions that meet the evolving needs of the construction industry. As the demand for quality, efficiency, and sustainable practices continues to rise, the role of tile roll forming machine manufacturers will only become more critical.

Investing in the right machine not only enhances production capabilities but also significantly contributes to the overall quality of construction projects. In a world that increasingly prioritizes efficiency and sustainability, tile roll forming machines stand as a testament to the blend of innovation and practicality within the manufacturing sector. With ongoing advancements, the future for tile roll forming machine manufacturers looks promising, ensuring that they remain integral to the construction industry's growth and evolution.

-

Optimizing Your Production with CZ Purlin MachinesNewsMay.19, 2025

-

Maximizing Efficiency with C and U Channel Roll Forming MachinesNewsMay.19, 2025

-

Investing in Z Purlin MachinesNewsMay.19, 2025

-

Efficient Solutions with Metal Stud and Track Roll Forming MachinesNewsMay.19, 2025

-

Choosing the Best C Purlin MachinesNewsMay.19, 2025

-

Boost Your Production with Wall Angle Roll Forming MachinesNewsMay.19, 2025

-

Understanding Steel Coil Cutting Machines and Their ImportanceNewsMay.16, 2025