Advanced Roof Production Machinery for Efficient Manufacturing Processes

The Innovations in Roof Manufacturing Machines

The roofing industry has experienced significant transformations over the years, primarily due to advancements in technology. Roof manufacturing machines, which form the backbone of this industry, have evolved to meet the growing demand for quality roofing materials. These machines are essential for producing a variety of roofing products, including shingles, tiles, and metal sheets, each with its unique characteristics and applications. In this article, we will explore the innovations in roof manufacturing machines, their importance, and the future of this industry.

Understanding Roof Manufacturing Machines

Roof manufacturing machines are specialized equipment designed to produce roofing materials efficiently and with precision. These machines employ various processes, including cutting, molding, and finishing, to create products that meet the specific needs of the construction industry. Enhanced automation and computer-aided design (CAD) technologies have enabled manufacturers to streamline these processes, reducing production times and increasing output while maintaining high-quality standards.

Technological Advancements

One of the most significant advancements in roof manufacturing machines is the adoption of automation. Automated machines can operate continuously, minimizing human error and maximizing productivity. High-speed roofing machine lines can produce thousands of shingles or tiles per hour, making it possible to meet the rising demand for roofing materials in both residential and commercial sectors. Additionally, automation allows for better consistency in product quality.

Another key innovation is the integration of digital technologies into manufacturing processes. Many modern roof manufacturing machines are equipped with smart sensors and data analytics capabilities. These technologies enable manufacturers to monitor machine performance in real-time, predict potential failures, and perform maintenance proactively. By leveraging data analytics, manufacturers can optimize production schedules and material usage, significantly reducing waste and costs.

Sustainability in Roof Manufacturing

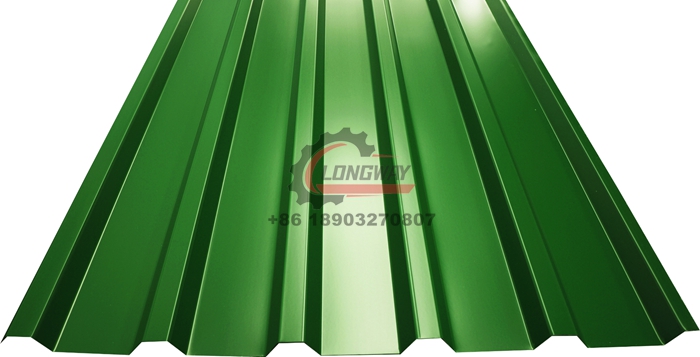

roof manufacturing machine

Sustainability has become a cornerstone of many manufacturing industries, including roofing. Roof manufacturing machines are now designed to produce materials that are not only durable but also environmentally friendly. For example, some machines can process recycled materials into high-quality roofing products, reducing the demand for new raw materials and minimizing environmental impact.

Additionally, many roofing manufacturers are exploring the use of solar panels and green roofing technologies. Machines that support the manufacture of solar-integrated roofing systems are becoming increasingly important. These systems are designed to harness solar energy, offering a sustainable energy source while providing traditional roofing services. The incorporation of such technologies into roof manufacturing machines signifies a forward-thinking approach that prioritizes the environment and energy efficiency.

Market Demand and Future Prospects

As urbanization continues to rise globally, the demand for roofing materials is expected to grow significantly. Factors such as population growth, climate change, and economic development are driving the need for more robust and efficient roofing solutions. In response to this demand, roof manufacturing machines will need to evolve further, embracing new materials and manufacturing techniques.

In the coming years, we may see increased interest in advanced materials like lightweight composites and insulated roofing systems. Roof manufacturing machines capable of producing these innovative materials will be crucial in addressing market needs. Moreover, the rise of prefabricated construction methods could lead to significant changes in roofing manufacturing, with machines that facilitate off-site production of roofing systems becoming more prevalent.

Conclusion

The landscape of roof manufacturing is changing rapidly due to technological advancements, sustainability initiatives, and evolving market demands. Roof manufacturing machines are at the forefront of this transformation, enabling manufacturers to produce high-quality roofing materials efficiently and sustainably. As the industry moves forward, the focus will likely remain on innovation—finding new ways to enhance productivity while minimizing environmental impact. In this context, the importance of sophisticated roof manufacturing machines cannot be overstated. They are not just tools of production; they are vital components driving the future of roofing and construction industries worldwide.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025