roll forming machine for steel

Roll Forming Machines for Steel An Overview

Roll forming is a versatile manufacturing process that is primarily used to create long lengths of steel components with consistent cross-sectional profiles. This innovative technique is widely utilized in various industries, including construction, automotive, and appliance manufacturing. Roll forming machines are essential for producing a variety of steel products, such as roof panels, wall panels, and other structural components. This article delves into the principles of roll forming, the advantages of using roll forming machines for steel, and their applications in different sectors.

The Roll Forming Process

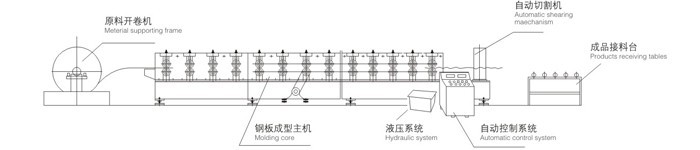

The roll forming process involves feeding a continuous strip of metal, typically steel, through a series of rollers that gradually shape the material into the desired cross-sectional profile. The rollers are arranged in a sequence, with each set of rollers performing a specific task in the shaping process. As the steel strip passes through the rollers, it is progressively bent and formed until it reaches the final shape. This process is highly efficient, enabling manufacturers to produce high volumes of uniform products.

Advantages of Roll Forming

1. Efficiency and Speed One of the primary advantages of roll forming is its efficiency. Once the tooling is set up, roll forming can operate at high speeds, producing components in continuous lengths. This capability allows manufacturers to meet high demand and keep production costs down.

2. Material Utilization Roll forming minimizes waste as it utilizes the entire width of the steel strip. Unlike other manufacturing processes, which may involve cutting and reshaping, roll forming allows manufacturers to create precise shapes without the need for excessive material loss.

3. Consistency and Precision Roll forming machines are designed to produce uniform products with consistent dimensions and tolerances. This repeatability is vital for industries where precise measurements are crucial, such as in the construction of pre-engineered buildings and industrial facilities.

4. Versatility Roll forming can be adapted to create a wide range of shapes and profiles, from simple angles to complex custom designs. This flexibility makes it suitable for various applications, allowing manufacturers to respond quickly to changing market demands.

roll forming machine for steel

5. Strength and Durability Steel components produced through roll forming are known for their strength and durability. The process often involves the use of high-strength materials, making the products ideal for applications requiring structural integrity.

Applications in Various Industries

Roll forming machines for steel are used in numerous sectors

- Construction In the construction industry, roll-formed steel is widely utilized for producing roofing and wall panels, guttering systems, and purlins. These components provide structural support and are essential for various architectural designs.

- Automotive The automotive industry employs roll forming to manufacture parts such as bumpers, frames, and other structural elements. The strength and lightweight nature of roll-formed components contribute to the overall performance and efficiency of vehicles.

- Appliances Household appliances, including refrigerators and washing machines, benefit from roll-formed steel components that offer both aesthetic appeal and structural support.

Conclusion

Roll forming machines for steel play a critical role in modern manufacturing. Their ability to produce high volumes of consistent, efficient, and durable components makes them invaluable across various industries. As technology advances, roll forming processes continue to improve, offering greater precision and flexibility. For manufacturers looking to optimize their production capabilities, investing in advanced roll forming technologies is essential to stay competitive in today's fast-paced market. With the ongoing demand for steel products, the significance of roll forming machines will only continue to grow.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025