roll forming equipment manufacturer

The Evolution and Importance of Roll Forming Equipment Manufacturers

In the realm of metal fabrication, the roll forming process has garnered significant attention for its efficiency, precision, and versatility. Central to this process are roll forming equipment manufacturers, who play a crucial role in designing and producing the machines that facilitate the continuous bending of metal sheets into desired shapes. As industries evolve and demand for customized products increases, the importance of these manufacturers cannot be overstated.

Understanding Roll Forming

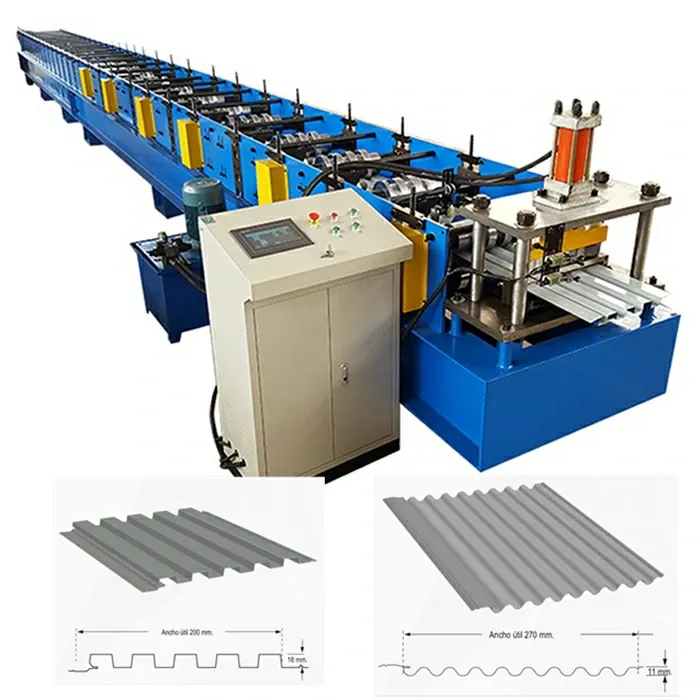

Roll forming is a progressive process that involves feeding a coil of metal through a series of rollers, each designed to bend the material incrementally. This technique is particularly beneficial for producing long lengths of uniform cross-sectional profiles, making it ideal for applications in construction, automotive, and appliances. The roll forming process allows for high production rates, minimal waste, and high repeatability, which is vital in today’s competitive market.

The Role of Manufacturers

Roll forming equipment manufacturers are the backbone of this process. They design and construct the machinery necessary for efficient roll forming operations. These manufacturers must consider various factors, including material thickness, type of material, desired profile, and production speed. The equipment must be tailored to meet the specific needs of each application, which requires a deep understanding of engineering, material science, and industry requirements.

Innovation and technology play key roles in the evolution of roll forming equipment. Traditionally, roll forming machines were simple hydraulic or mechanical devices. However, advancements in technology have led to the development of sophisticated machines featuring CNC controls, automated setup, and integrated monitoring systems. These innovations allow manufacturers to produce complex profiles with precision while reducing lead times and overall costs.

Key Features of Roll Forming Equipment

Modern roll forming equipment comes equipped with several features that enhance productivity and efficiency

. These include1. Adjustable Roll Sets To accommodate various profiles, modern machines have adjustable roll sets that can be easily configured for different production runs, ensuring flexibility.

roll forming equipment manufacturer

2. High-Speed Operation Many manufacturers design machines capable of operating at high speeds without sacrificing quality, which is a significant advantage in a fast-paced production environment.

3. Quality Control Systems Automated quality control measures, such as real-time monitoring and feedback systems, help maintain consistency in product quality and reduce material waste.

4. Energy Efficiency With an increasing focus on sustainability, manufacturers are developing energy-efficient machines that minimize power consumption during operation.

5. User-Friendly Interfaces Modern roll forming machines often come with intuitive software interfaces that allow operators to easily program the equipment and monitor production processes.

Challenges and Opportunities

Despite the advancements, roll forming equipment manufacturers face several challenges. The need for continuous innovation is paramount, as competitors strive to offer better, faster, and more cost-effective solutions. Additionally, fluctuating raw material costs and supply chain disruptions can impact production schedules and pricing strategies.

However, these challenges also present opportunities. As industries seek to reduce their carbon footprints, there is a growing demand for environmentally friendly manufacturing processes. Roll forming, which typically generates less waste compared to traditional cutting methods, is well-positioned to capitalize on this trend. Furthermore, the expansion of industries such as renewable energy and electric vehicles presents new markets for roll forming solutions.

Conclusion

Roll forming equipment manufacturers are essential players in the metal fabrication industry, enabling the production of complex, high-quality components at scale. Their commitment to innovation and quality helps meet the growing demands of various sectors while navigating the challenges of a dynamic marketplace. As technology continues to advance, these manufacturers will remain at the forefront, shaping the future of metal fabrication. The continuous development and refinement of roll forming equipment will undoubtedly lead to new possibilities and opportunities in the manufacturing world.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025