Innovative Solutions from Leading Panel Roll Former Manufacturers for Your Construction Needs

The Rise of R-Panel Roll Formers Revolutionizing the Metal Construction Industry

In recent years, the construction industry has witnessed a significant shift toward innovative building materials and technologies. Among these advancements, the R-panel roll former has emerged as a game-changer, particularly in the realm of metal building systems. Manufactured by specialized factories, these machines have revolutionized how roofing and siding panels are produced, offering a blend of efficiency, durability, and sustainability.

What Is an R-Panel Roll Former?

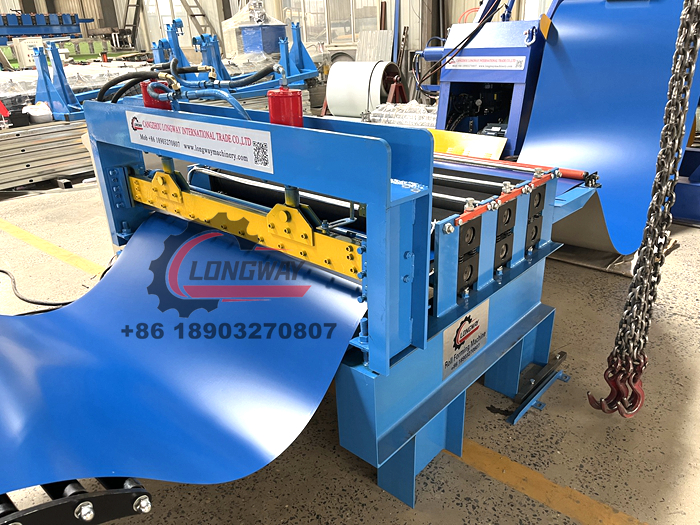

An R-panel roll former is a piece of industrial equipment used to create R-panel metal sheets, which are commonly utilized in commercial and industrial buildings. The R-panel, characterized by its unique ribbed design, provides significant structural integrity and aesthetic appeal. The roll forming process involves feeding metal coils into the machine that progressively shapes the material into the desired profile through a series of rollers. This method not only ensures precision but also enhances production speed, making it a favorite among manufacturers.

Benefits of R-Panel Roll Forming

1. Efficiency and Speed R-panel roll formers can produce large quantities of panels in a relatively short time frame. This efficiency not only meets the demands of large construction projects but also reduces labor costs, allowing manufacturers to optimize their operations.

2. Quality Control The automated nature of roll forming minimizes the risk of human error during the production process. This results in high-quality panels that meet stringent industry standards. Additionally, modern roll formers are equipped with advanced technology that allows for real-time monitoring, ensuring consistent quality across batches.

3. Material Versatility These machines can accommodate various metal materials, including galvanized steel, aluminum, and copper. This flexibility enables manufacturers to cater to a diverse set of client needs, whether it's for roofing, siding, or other architectural applications.

r panel roll former factory

4. Customization R-panel roll formers offer the option for customization in terms of thickness, color, and finish. This ability to tailor products aligns with contemporary design requirements, making R-panels a go-to choice for architects and builders.

5. Sustainable Building Practices With increasing emphasis on sustainability in construction, R-panel roll forming aligns well with eco-friendly practices. Metal panels are recyclable, and the efficient use of materials in the roll forming process minimizes waste, contributing to greener building designs.

The Factory Perspective

From a manufacturing standpoint, the investment in R-panel roll forming equipment has proven to be beneficial. Factories can streamline their production processes, reduce overhead costs, and respond quickly to market demands. Advanced factory setups often incorporate automation and robotics, further enhancing productivity and safety on the manufacturing floor.

Moreover, R-panel manufacturers typically benefit from a strong supply chain network. By partnering with reliable suppliers and establishing efficient distribution channels, they can ensure timely deliveries to construction sites, preventing delays in project timelines.

Conclusion

The advent of R-panel roll formers has undoubtedly transformed the metal construction landscape. With their unmatched efficiency, quality, and design flexibility, these machines have become essential tools in modern manufacturing. As the demand for sustainable and durable building materials continues to rise, the role of R-panel roll formers will likely expand, driving further innovations in the industry. For builders and architects alike, leveraging the capabilities of R-panel roll forming offers a pathway to delivering high-quality, aesthetically pleasing, and sustainable structures that meet the needs of today’s markets.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025