custom track roll forming machine

Custom Track Roll Forming Machines A Revolutionary Approach to Metal Fabrication

In the rapidly evolving world of manufacturing, the demand for efficiency, precision, and customized solutions has never been higher. Among the many technological advancements that have emerged in recent years, custom track roll forming machines stand out for their ability to produce complex metal profiles with pinpoint accuracy. This article explores the significance of these machines in modern manufacturing, their unique features, and their applications across various industries.

Understanding Roll Forming Technology

Roll forming is a continuous bending operation in which a long strip of metal is fed through consecutive pairs of rolls to form a desired cross-sectional shape. This process is particularly advantageous for producing long lengths of uniform cross-section profiles, making it ideal for large-scale operations. The primary benefit of roll forming is its ability to maintain structural integrity and uniformity throughout the process, providing end products that can meet stringent quality standards.

Custom Track Roll Forming Machines What Sets Them Apart?

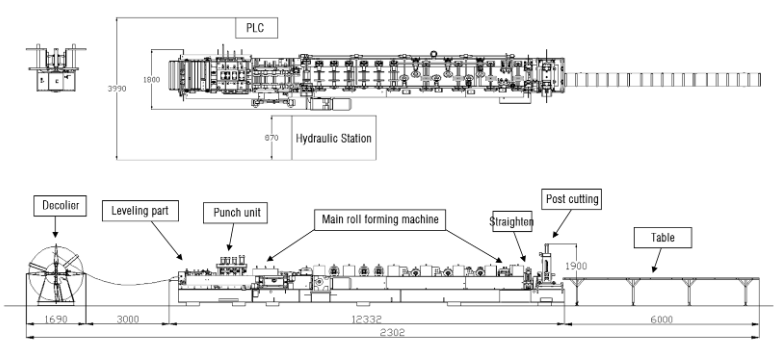

Custom track roll forming machines specifically cater to the need for tailored profiles. Unlike standard roll forming machines that produce generic shapes, custom machines are designed to create unique profiles based on client specifications. This flexibility is essential in industries where components must fit specific dimensions or requirements, such as the automotive, construction, and agricultural sectors.

One of the key features of custom track roll forming machines is their adaptability. They can be engineered to accommodate various materials, including aluminum, steel, and other alloys, allowing manufacturers to switch between materials based on project needs. Additionally, these machines can produce a wide range of profile sizes and shapes, from simple tracks to intricate designs, which can be crucial for specialized applications.

Benefits of Custom Track Roll Forming Machines

1. High Precision Custom track roll forming machines offer exceptional accuracy, which is critical in industries where every millimeter counts. By minimizing tolerances, these machines reduce the need for secondary operations, saving both time and cost. 2. Reduced Waste The efficiency of the roll forming process means that metal waste is minimized. This not only lowers material costs but also aligns with sustainable manufacturing practices by reducing the environmental impact of production.

3. Increased Production Speed The automation and continuous operation capabilities of these machines allow manufacturers to increase their production rates significantly. This is especially beneficial in high-demand industries where turnaround times are crucial.

custom track roll forming machine

4. Versatility Custom track roll forming machines can produce a diverse range of products, from basic structural components to complex tracks for specialized machinery. This versatility enhances manufacturing capabilities and opens new avenues for innovation.

5. Cost-Effectiveness While the initial investment in custom machinery may be higher, the long-term savings developed from reduced material waste, lower labor costs, and increased productivity often outweigh these costs.

Applications Across Industries

Custom track roll forming machines are utilized in various sectors, including

- Automotive In the automotive industry, these machines fabricate components such as chassis and support structures, which require high strength and precision. - Construction For the construction sector, custom profiles for tracks and supports used in architectural designs are created to meet specific building codes and aesthetics.

- Agricultural Equipment Custom roll forming plays a crucial role in manufacturing components of agricultural machinery, where durability and efficiency directly impact operational outcomes.

- Furniture Manufacturing The furniture industry also benefits from custom track roll forming machines, producing unique metal profiles that enhance the design and functionality of various products.

Conclusion

As industries continue to evolve and demand for customized solutions grows, custom track roll forming machines become an essential asset in the manufacturing landscape. Their ability to provide high precision, reduce waste, increase production speed, and adapt to various materials and designs makes them a vital tool for businesses seeking to stay competitive. By embracing this technology, manufacturers can not only improve their operational efficiencies but also open new pathways for innovation that can define the future of production.

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025