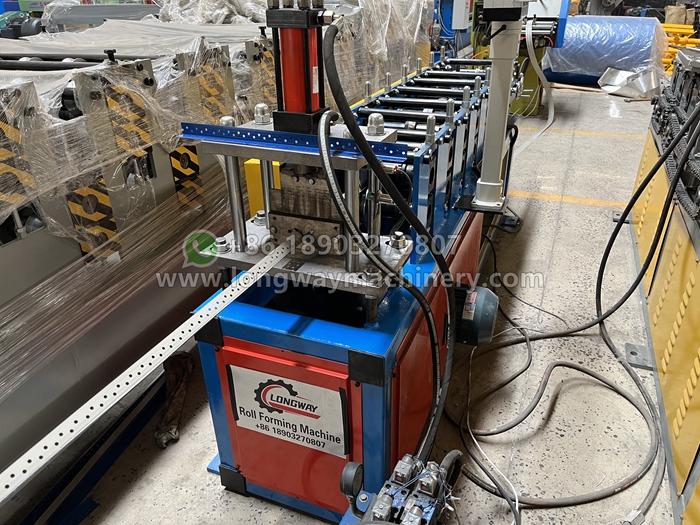

custom metal roofing panel machine

The Evolution and Benefits of Custom Metal Roofing Panel Machines

In the construction industry, innovation is a critical driver of efficiency and quality. One area that has seen significant technological advancements is roofing. Among the most notable developments are custom metal roofing panel machines. These machines have revolutionized the way metal roofs are manufactured, allowing for greater versatility, speed, and precision. This article delves into the features and advantages of these machines, exploring how they have transformed the metal roofing landscape.

Understanding Custom Metal Roofing Panel Machines

Custom metal roofing panel machines are specialized equipment designed to produce metal roofing panels tailored to specific measurements and styles. The machines utilize advanced technologies such as Automated Computer Numerical Control (CNC) systems and programmable logic controllers (PLCs), enabling them to produce panels with high accuracy and consistency. Whether it’s for residential, commercial, or industrial applications, these machines can manufacture a variety of panel types, including standing seam, corrugated, and flat panels.

Advantages of Custom Metal Roofing Panels

1. Versatility in Design One of the most significant benefits of using custom metal roofing panel machines is the ability to create a wide range of designs. Builders and architects can choose different materials, finishes, and colors, allowing for unique aesthetics that complement various architectural styles. This flexibility means that they can meet the specific demands of each project, enhancing creativity in design.

2. Precision Engineering Precision is paramount in roofing installation, and custom metal roofing panel machines excel in this area. The automated systems ensure that each panel is cut and shaped to exact specifications, reducing the likelihood of human error. This level of precision not only improves the overall quality of the roofing system but also simplifies the installation process, as the panels fit together seamlessly.

custom metal roofing panel machine

3. Enhanced Durability Metal roofing materials are inherently durable, but the customization potential takes it a step further. By using high-quality materials and finishes, custom machines can produce panels that resist corrosion, fading, and wear. This durability not only leads to a longer lifespan for the roof but also minimizes maintenance costs for homeowners and business owners alike.

4. Quick Production Times Traditional roofing fabrication can be time-consuming, especially when working with various sizes and designs. Custom metal roofing panel machines drastically reduce production times. Their automated processes allow manufacturers to quickly switch from one design to another without significant downtime, ensuring that projects stay on schedule and within budget.

5. Cost Efficiency While the initial investment in custom metal roofing panel machines can be significant, the long-term savings are undeniable. By reducing labor costs and material waste through precise manufacturing, these machines offer a cost-effective solution over the lifespan of both the machine and the roofing system. Furthermore, the speed of production allows companies to take on more projects, increasing their revenue potential.

6. Sustainability In today’s eco-conscious market, sustainability is more important than ever. Metal roofing is often made from recycled materials, and the custom manufacturing process can further minimize waste. Additionally, metal roofing systems can contribute to energy efficiency by reflecting heat and reducing cooling costs in commercial and residential buildings.

Conclusion

Custom metal roofing panel machines represent a significant leap forward in roofing technology. Their ability to produce a wide array of designs with unparalleled precision makes them an asset for manufacturers, builders, and architects alike. The advantages—ranging from enhanced durability and cost efficiency to sustainability—position metal roofing panels as an attractive option within the industry.

As the demand for custom solutions and high-quality materials continues to rise, investment in these advanced machines is expected to grow. For businesses looking to stay ahead in the competitive construction market, embracing the capabilities of custom metal roofing panel machines is not just a choice—it’s a necessity. By doing so, they will not only meet client expectations but also contribute to a more innovative, sustainable, and efficient future for the roofing industry.

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025