Cost Analysis for Manufacturing Plants Producing Roofing Sheets by Leading Industry Manufacturers

The Economics of Roofing Sheet Manufacturing Plants

The construction industry has seen significant growth over the past few decades, creating a rising demand for roofing materials. Among the various options available, roofing sheets made from materials like metal, PVC, and polycarbonate have gained immense popularity due to their durability, lightweight nature, and aesthetic appeal. As a result, establishing a roofing sheet manufacturing plant has emerged as a lucrative venture. However, prospective investors must consider various factors that influence the costs involved.

Initial Capital Expenditure

Setting up a roofing sheet manufacturing plant involves substantial initial capital investment. This expenditure includes costs for land acquisition, construction of the facility, purchase of machinery, and installation of production lines. Depending on the scale of the operation, the costs can vary significantly. For example, a small-scale operation focusing on niche products may require a lower investment, while a large-scale facility aimed at mass production of diverse roofing sheets demands a larger financial outlay.

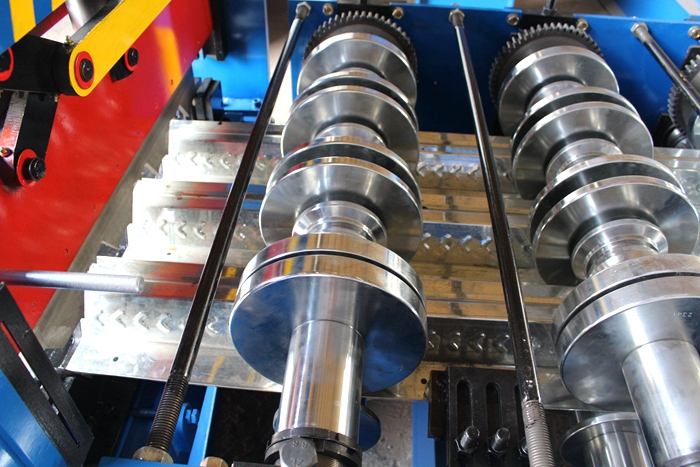

The machinery required for roofing sheet production includes roll-forming machines and cutting equipment, which can be expensive. Additionally, advanced technology, like automated systems, can enhance production efficiency but also raises startup costs. Therefore, planning for both machinery procurement and facility setup is critical in the initial phases.

Operating Expenses

Once the plant is established, operating expenses become crucial to maintaining profitability. These expenses encompass raw materials, labor, utilities, and maintenance. The choice of materials used in production significantly impacts cost. For instance, metal sheets may require different kinds of raw components compared to PVC or polycarbonate sheets, affecting overall material costs.

Labor costs can fluctuate based on the location of the manufacturing plant and the skills required for the job. Hiring skilled labor can typically lead to better product quality and increased operational efficiency but may further raise operational costs. Therefore, investors should evaluate local labor markets to assess the feasibility of hiring qualified personnel within budget constraints.

roofing sheet manufacturing plant cost manufacturers

Market Demand and Competition

Understanding market demand is essential in determining the financial viability of a roofing sheet manufacturing plant. The demand for roofing sheets can be influenced by various factors, including construction trends, economic conditions, and geographical considerations. For example, areas prone to extreme weather conditions may have a higher demand for durable roofing solutions.

Furthermore, competition plays a significant role in pricing strategy. An analysis of the local and regional market is vital for identifying potential competitors, which can influence pricing structures. Offering unique products, such as eco-friendly roofing sheets, can differentiate a business in a competitive landscape and help protect profit margins.

Regulatory Compliance and Environmental Considerations

Manufacturers must adhere to various regulations concerning safety, quality standards, and environmental impact. Compliance with local and national regulations can add to operational costs. However, investing in environmentally friendly production processes and materials can not only mitigate regulatory risks but also cater to a growing market segment that prioritizes sustainability.

Conclusion

In conclusion, the establishment of a roofing sheet manufacturing plant involves numerous financial considerations. From initial capital investments to ongoing operation costs, each aspect must be meticulously planned and executed to ensure profitability. Understanding market dynamics and regulatory compliance is equally crucial. For entrepreneurs and investors, success in this industry not only rests on effective management but also on the ability to adapt to changing market needs and technological advancements. With the right strategies in place, investing in a roofing sheet manufacturing plant can be a rewarding business endeavor that thrives amid the growing demands of the construction sector.

-

The Latest Trends in Cut to Length Equipment and MachinesNewsMay.09, 2025

-

Revolutionizing Door Frame Production: The Power of Modern MachinesNewsMay.09, 2025

-

Revolutionary Machines for Roller Shutter and Garage DoorsNewsMay.09, 2025

-

Everything You Need to Know About Gutter Roll Forming MachinesNewsMay.09, 2025

-

Efficiency in Coil Handling with Hydraulic Decoiler MachinesNewsMay.09, 2025

-

Downspout Roll Forming Machines and Their ValueNewsMay.09, 2025

-

Revolutionizing the Door Frame Industry: Key Insights on Roll Forming MachinesNewsApr.18, 2025