corrugated roof sheet roll forming machine company

The Importance of Corrugated Roof Sheet Roll Forming Machines

In the construction industry, the demand for durable, lightweight, and cost-effective roofing solutions has led to the widespread adoption of corrugated roof sheets. These sheets are not only aesthetically pleasing but also offer excellent protection against the elements. Central to the production of these essential roofing materials is the corrugated roof sheet roll forming machine, a sophisticated piece of equipment designed to streamline the manufacturing process.

What is a Corrugated Roof Sheet Roll Forming Machine?

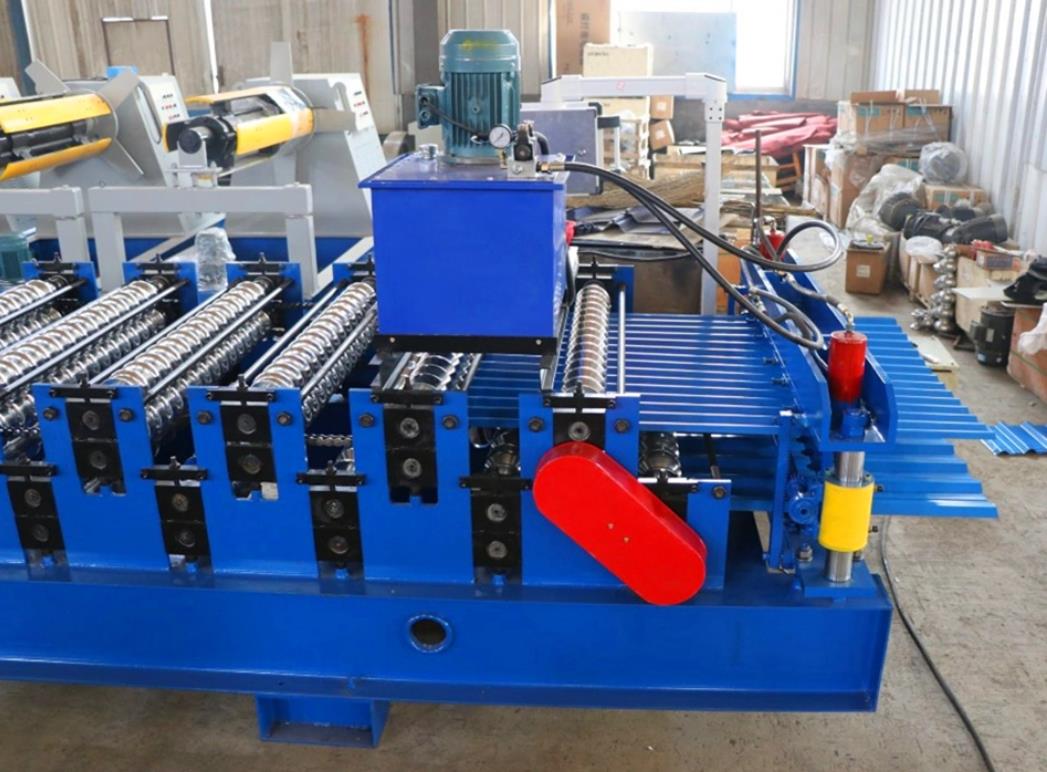

A corrugated roof sheet roll forming machine is a specialized industrial machine that transforms flat metal sheets into corrugated roofing panels through a continuous and automated process. It typically consists of a series of rollers that shape the metal sheet as it passes through the machine, creating the distinctive wave-like pattern characteristic of corrugated roofing. This process greatly improves the structural integrity of the sheet while also enhancing its aesthetic appeal.

Technology and Features

Modern corrugated roof sheet roll forming machines are equipped with advanced technology that improves precision and efficiency. They often feature programmable logic controllers (PLCs) that allow operators to set specific parameters for the desired height, width, and thickness of the corrugated sheets. Some machines are designed for quick changeovers, enabling manufacturers to switch between different profiles with minimal downtime.

Additionally, many machines come with integrated systems for cutting, stacking, and even packaging the finished sheets, thereby automating the entire production process. This level of automation not only reduces labor costs but also minimizes the risk of human error, ensuring a higher quality product.

Benefits of Using Corrugated Roof Sheet Roll Forming Machines

1. Cost-Effectiveness By producing sheets in large quantities with minimal manual intervention, manufacturers can significantly reduce production costs. The efficiency of these machines translates into lower labor costs and faster turnaround times, which can make a substantial difference in profit margins.

corrugated roof sheet roll forming machine company

2. Versatility Corrugated roof sheet roll forming machines can be adjusted to create different profiles based on specific project requirements. This adaptability makes them suitable for a wide range of applications, from residential buildings to industrial structures.

3. Durability and Strength The corrugated design not only improves the aesthetic qualities of the roofing materials but also enhances their strength. Corrugated sheets are better at distributing weight and resisting impact, making them an ideal choice for areas with high winds or heavy rainfall.

4. Environmental Impact Many manufacturers focus on sustainability by using recycled materials in their production processes. Additionally, the long lifespan of corrugated roofing contributes to reduced waste over time, making it an environmentally friendly option.

5. Easy Installation Corrugated roof sheets produced by roll forming machines are lightweight and easy to handle, allowing for quicker and more straightforward installation. This feature can be particularly advantageous for construction projects on tight deadlines.

Choosing the Right Manufacturer

When looking to invest in a corrugated roof sheet roll forming machine, it is crucial to select a reputable manufacturer. Factors to consider include the machine's production capacity, customization options, after-sales support, and warranty terms. A reliable manufacturer should not only provide high-quality machines but also offer training and technical support to ensure that operators can make the most of the equipment.

Conclusion

The corrugated roof sheet roll forming machine is a cornerstone of modern construction and roofing industries. Its advanced technology and numerous benefits make it a valuable investment for manufacturers aiming to meet the growing demand for quality roofing solutions. As the industry continues to evolve, these machines will play an increasingly important role in shaping the future of building materials, ensuring that they are not only functional but also sustainable and aesthetically pleasing. In a world where efficiency and sustainability are paramount, the corrugated roof sheet roll forming machine stands out as a vital asset in the construction landscape.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025