corrugated roof sheet machine price factories

Understanding the Price Factors of Corrugated Roof Sheet Machines

In the modern construction and manufacturing industries, the demand for durable and cost-efficient roofing solutions has led to the widespread use of corrugated roof sheets. These sheets are not only lightweight and easy to install but also provide excellent protection against weather elements, making them a popular choice in residential and commercial buildings. The machinery used to produce these corrugated roof sheets plays a pivotal role in meeting demand. However, potential buyers often wonder about the prices of corrugated roof sheet machines and the factors that influence these costs.

1. Machine Specifications and Features

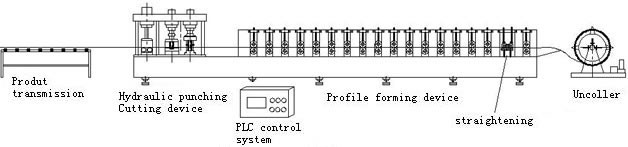

The price of corrugated roof sheet machines can vary significantly based on their specifications and features. Basic machines that perform standard operations may be available at lower prices. In contrast, advanced machines equipped with features such as computerized controls, automatic feeding systems, and enhanced cutting capabilities typically come at a higher cost. Additionally, machines that can produce multiple types of corrugated profiles or those designed for high-speed production will generally command higher prices due to their increased functionality and productivity.

2. Production Capacity

Another critical factor that affects the price of corrugated roof sheet machines is their production capacity. Machines with higher output capabilities, capable of producing large volumes of roof sheets in a shorter timeframe, tend to be more expensive. This is because they often require more robust components and advanced technology to maintain efficiency and quality during high-speed operations. Buyers must assess their production needs to choose a machine that balances capacity and cost-effectiveness.

3. Material Quality and Construction

The materials used in the construction of the machines themselves can also impact pricing. High-quality steel and durable components may result in a higher initial investment but can significantly reduce maintenance costs and extend the machine's lifespan. While lower-cost machines made from less durable materials might seem attractive initially, they can lead to increased long-term expenses due to frequent repairs or early replacement.

corrugated roof sheet machine price factories

4. Brand Reputation and Manufacturer

The manufacturer’s reputation can greatly influence the pricing of corrugated roof sheet machines. Established brands with a history of reliability and quality may charge a premium for their products. These brands often provide better after-sales support, warranty options, and access to spare parts, which can be invaluable to buyers. On the other hand, newer or lesser-known manufacturers may offer lower prices, but potential buyers should thoroughly research the brand's reliability and the quality of their machines before making a purchase.

5. Technological Innovations

The evolution of technology in manufacturing processes has also introduced several innovations that can affect prices. Machines that incorporate the latest technology, such as automation and IoT capabilities, generally offer enhanced efficiency and can reduce labor costs. However, investing in such advanced machinery often comes with a higher price tag. Companies looking to stay competitive may find that the benefits of these innovations outweigh the initial costs.

6. Geographic Location and Shipping

The geographic location of the manufacturing facility and the destination for the machine delivery can also affect pricing. Import duties, shipping costs, and local taxes can add significant expenses to the overall cost of the machine. It is advisable for buyers to consider the total cost of ownership, including shipping and installation, rather than focusing solely on the machine's initial purchase price.

Conclusion

When considering the purchase of a corrugated roof sheet machine, potential buyers need to evaluate various factors that influence price. From machine specifications and production capacity to material quality and manufacturer reputation, each aspect plays a pivotal role in determining the final cost. By conducting thorough research and understanding these elements, buyers can make informed decisions that align with their production needs and budget, ensuring a positive return on investment in the long run.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025