High-Quality Corrugated Roll Forming Machines Available from Trusted Manufacturers for Sale

The Rise of Corrugated Roll Forming Machines in Manufacturing

In the fast-paced world of manufacturing, efficiency and customization are paramount. Among various production techniques, the use of corrugated roll forming machines has emerged as a significant trend, revolutionizing the way corrugated materials are produced. This innovation primarily serves industries such as construction, packaging, and automotive, with a growing number of factories now offering these machines for sale.

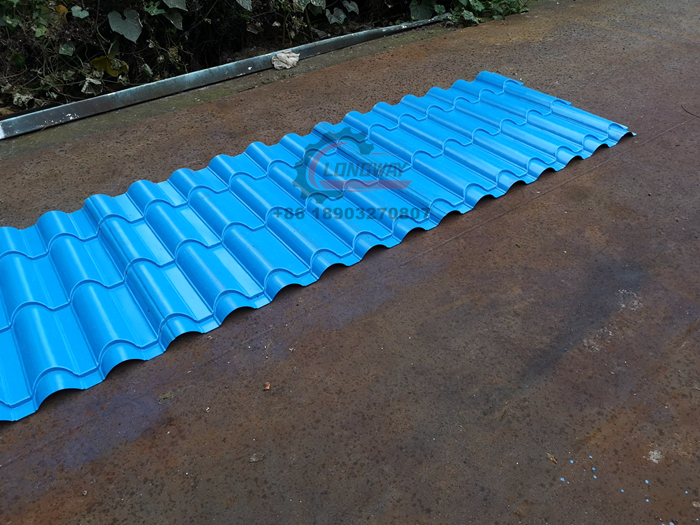

Corrugated roll forming machines are specifically designed to produce corrugated sheets, which are widely used for their strength-to-weight ratio and durability. This type of machinery utilizes a continuous process to roll metal sheets through a series of precisely shaped rollers, which gradually alter their form into the desired corrugated profile. The result is a high-quality product that can be tailored to meet specific requirements in terms of thickness, width, and corrugation depth.

One of the primary advantages of investing in a corrugated roll forming machine is the efficiency it brings to production. These machines can operate at high speeds, significantly reducing the time required to manufacture corrugated sheets compared to traditional methods. This not only cuts down on labor costs but also allows factories to respond quickly to changing market demands. As companies strive to meet the needs of their customers in real time, the speed and flexibility provided by such machines are invaluable.

Moreover, advancements in technology have enabled the integration of automation and computer-aided design (CAD) with rolling machines. Modern corrugated roll forming machines come equipped with sophisticated software that allows manufacturers to create precise designs quickly. This means businesses can produce customized corrugated profiles without the lengthy setup times that were once necessary. Such flexibility is particularly beneficial in industries like construction, where specific architectural designs may require unique corrugated materials.

corrugated roll forming machine for sale factories

The durability of products made from corrugated materials produced by these machines is another significant selling point. Corrugated sheets exhibit excellent thermal insulation properties and can withstand harsh environmental conditions, making them an ideal choice for roofing and wall coverings in both commercial and residential projects. As sustainability becomes a priority for many industries, the recyclable nature of corrugated materials furthers their appeal.

As the demand for corrugated materials continues to grow, so does the competition among manufacturers. Factories offering corrugated roll forming machines for sale are leveraging this trend by providing a range of models tailored to different production needs and budgets. From small-scale operations to large manufacturing plants, there are options available to cater to a diverse customer base.

When purchasing a corrugated roll forming machine, potential buyers should consider several factors, including the machine's production capacity, energy efficiency, and ease of operation. It is also advisable to evaluate the reputation of the manufacturing company, as a reliable supplier will ensure quality machinery supported by excellent customer service.

In conclusion, the corrugated roll forming machine is an essential tool in modern manufacturing, increasing efficiency and enabling customization. As more factories present these machines for sale, businesses can take advantage of the opportunity to enhance their production capabilities. With continuous advancements in technology and an ever-growing demand for quality corrugated materials, the future looks bright for manufacturers embracing this innovative approach. Investing in a corrugated roll forming machine could very well be a game-changer in achieving business growth and competitiveness in today's market.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025