Cold Rolled Steel Channel Fabrication Machine for Efficient Roll Forming Solutions

The Importance of Cold Rolled Steel Channel Framing Roll Forming Machines

In the realm of modern construction and manufacturing, the efficiency and versatility of material processing techniques play a crucial role in determining the quality and cost-effectiveness of structural components. One such technique is the cold rolled steel channel framing roll forming process, facilitated by advanced machinery designed for precision and speed. This method has gained considerable traction in various industries due to its numerous advantages, making it a significant area of focus for engineers and manufacturers alike.

Understanding Cold Rolled Steel

Cold rolled steel is a type of steel that has been processed at room temperature, which means it is shaped and formed below its recrystallization temperature. This process enhances its mechanical properties, including strength, surface finish, and dimensional accuracy. The result is a material with higher tensile strength and better surface quality compared to hot rolled steel. Cold rolled steel channels are particularly popular for their excellent structural characteristics and aesthetic appeal, making them ideal for applications in construction, automotive, and various manufacturing sectors.

The Roll Forming Process

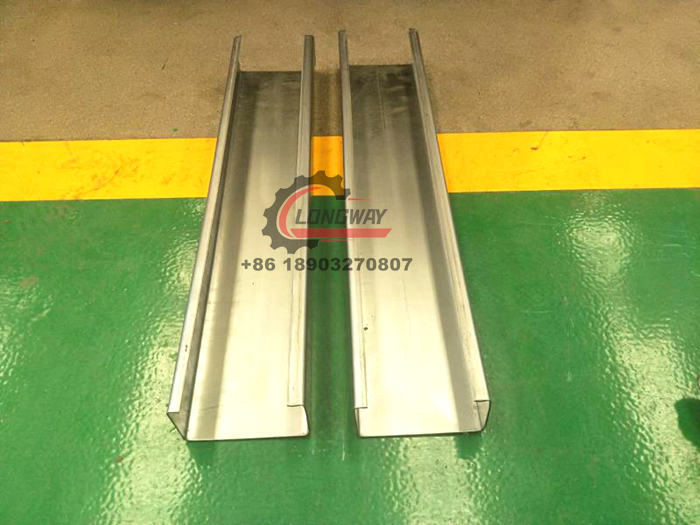

Roll forming is a continuous bending operation in which a long strip of metal is passed through a series of rollers to gradually shape it into the desired profile. In the case of cold rolled steel channels, the machine precisely molds the steel strip into the required channel configuration. This process not only increases the efficiency of production but also reduces waste, as it maximizes the use of raw materials.

The roll forming machine consists of various components, including feed mechanisms, forming stations, and cutting devices. The steel strip is fed into the machine, where it undergoes multiple stages of bending and shaping. Each roller in the series is designed with a specific profile that incrementally alters the shape of the material until it achieves the final desired form. Once the desired profile is achieved, the machine can be equipped with a shearing device to cut the formed channels to specified lengths.

Benefits of Using Roll Forming Machines

cold rolled steel channel framing roll forming machine

1. High Efficiency and Speed One of the significant advantages of cold rolled steel channel framing roll forming machines is their ability to produce large quantities of finished products in a short amount of time. This high-speed production capability significantly reduces labor costs and contributes to overall efficiency in manufacturing processes.

2. Precision Engineering Roll forming machines provide high levels of accuracy in shaping steel strips. The engineering behind these machines ensures that each channel produced meets stringent dimensional tolerances, which is essential for maintaining quality in construction applications.

3. Versatility in Design The design of roll forming machines allows for the creation of a wide variety of channel profiles and dimensions. This versatility enables manufacturers to cater to diverse industry requirements, from standard sizes to custom designs.

4. Material Savings The continuous nature of the roll forming process minimizes waste, as it allows for the precise cutting of the material. Manufacturers can expect lower scrap rates, leading to reduced material costs. Additionally, the strength of cold rolled steel means thinner gauges can often be used without compromising structural integrity.

5. Reduced Need for Secondary Operations Many cold rolled channel profiles often require minimal secondary operations, such as welding or additional machining. This means that the finished products can be used directly in construction or assembly, further saving time and resources.

Conclusion

Cold rolled steel channel framing roll forming machines represent a critical innovation in the manufacturing landscape. Their ability to produce high-quality, precision-engineered components quickly and efficiently has made them indispensable in various industries, particularly construction and manufacturing. As the demand for durable and aesthetically pleasing materials continues to rise, the role of these machines will only become more pronounced, driving advancements in technology and sustainability. Adopting roll forming technology not only boosts production capabilities but also enhances overall product quality, setting a standard for modern manufacturing processes. Embracing these machines is indeed a step toward a more efficient and sustainable future in structural framing design and manufacturing.

-

The Latest Trends in Cut to Length Equipment and MachinesNewsMay.09, 2025

-

Revolutionizing Door Frame Production: The Power of Modern MachinesNewsMay.09, 2025

-

Revolutionary Machines for Roller Shutter and Garage DoorsNewsMay.09, 2025

-

Everything You Need to Know About Gutter Roll Forming MachinesNewsMay.09, 2025

-

Efficiency in Coil Handling with Hydraulic Decoiler MachinesNewsMay.09, 2025

-

Downspout Roll Forming Machines and Their ValueNewsMay.09, 2025

-

Revolutionizing the Door Frame Industry: Key Insights on Roll Forming MachinesNewsApr.18, 2025