फरवरी . 15, 2025 14:16

Back to list

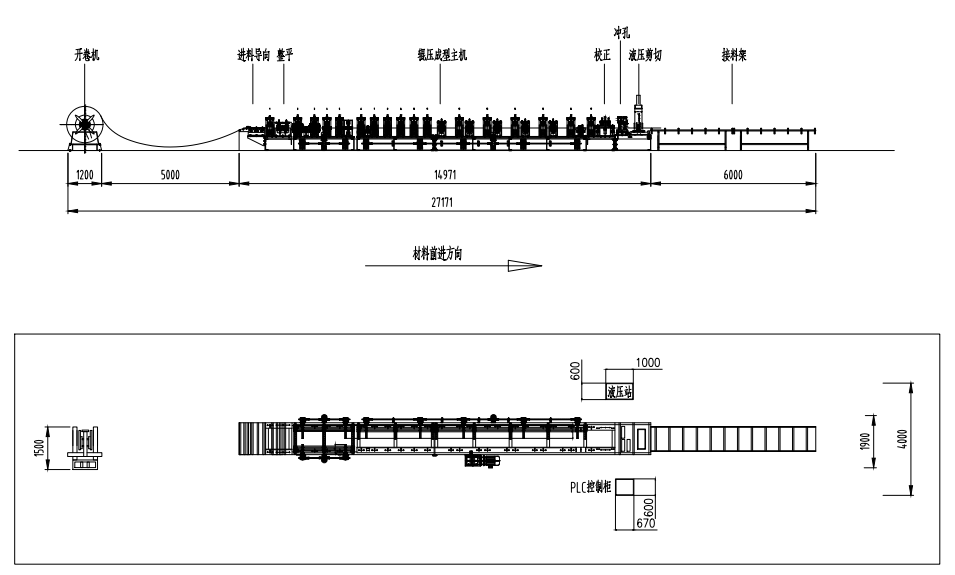

china steel profile roll forming machine

Navigating the comprehensive realm of steel profile roll forming machines can initially seem daunting for those not directly involved in the manufacturing and construction sectors. However, by diving deeper into their capabilities and applications, one can appreciate their pivotal role in modern industry. With over 20 years of experience working alongside both manufacturers and end-users of roll forming machines, insights into the features, benefits, and considerations when selecting such machines can greatly enhance one’s understanding.

In considering the trustworthiness of these machines and their output, it’s essential to address the maintenance and operational guidelines. Machines that are diligently maintained according to the manufacturer's specifications often outlast their expected operational life, delivering consistent performance over several decades. Regular training sessions for personnel not only improve the machine's output quality but also ensure a safe working environment, maximizing trust in both product and process. As a seasoned professional in the field of steel roll forming, investing time in understanding customer needs and customizing machine settings accordingly is invaluable. Such attention to detail not only aligns production capabilities with market demands but also reinforces the manufacturer's credibility as a reliable partner in the supply chain. Companies that effectively leverage the capabilities of steel profile roll forming machines find themselves at a competitive advantage, with the ability to swiftly adapt to changing market needs — be it bespoke project requirements or scaling up production for large-scale developments. The appreciation for these machines only deepens with an understanding of their evolution, from manual operations to sophisticated automated systems capable of real-time adjustments. In conclusion, exploring the rich landscape of steel profile roll forming machines reveals that their role extends far beyond mere production tools. They embody a fusion of mechanical precision, engineering genius, and strategic investment that powers the backbone of contemporary industrial infrastructures. For businesses aiming to establish themselves as leaders in steel fabrication, these machines offer nothing less than a gateway to excellence and innovation.

In considering the trustworthiness of these machines and their output, it’s essential to address the maintenance and operational guidelines. Machines that are diligently maintained according to the manufacturer's specifications often outlast their expected operational life, delivering consistent performance over several decades. Regular training sessions for personnel not only improve the machine's output quality but also ensure a safe working environment, maximizing trust in both product and process. As a seasoned professional in the field of steel roll forming, investing time in understanding customer needs and customizing machine settings accordingly is invaluable. Such attention to detail not only aligns production capabilities with market demands but also reinforces the manufacturer's credibility as a reliable partner in the supply chain. Companies that effectively leverage the capabilities of steel profile roll forming machines find themselves at a competitive advantage, with the ability to swiftly adapt to changing market needs — be it bespoke project requirements or scaling up production for large-scale developments. The appreciation for these machines only deepens with an understanding of their evolution, from manual operations to sophisticated automated systems capable of real-time adjustments. In conclusion, exploring the rich landscape of steel profile roll forming machines reveals that their role extends far beyond mere production tools. They embody a fusion of mechanical precision, engineering genius, and strategic investment that powers the backbone of contemporary industrial infrastructures. For businesses aiming to establish themselves as leaders in steel fabrication, these machines offer nothing less than a gateway to excellence and innovation.

Latest news

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

Related Products