C Channel Production Equipment Manufacturing Solutions for Efficient Construction Projects

Understanding the C Channel Making Machine Factory

In the world of manufacturing, efficiency and precision are paramount. One of the key players in this domain is the factory that produces C channel making machines. These machines are essential in the construction, automotive, and various fabrication industries due to their ability to create C-shaped channels used as structural components in a myriad of applications.

What is a C Channel?

A C channel, often referred to as a C-section steel or C profile, is a structural element primarily used in construction and engineering. The C shape allows for optimal strength-to-weight ratio, making it an ideal choice for beams, frames, and supports. These channels are typically made of mild steel, stainless steel, or aluminum, and their applications range from building frameworks to automotive parts.

The Role of C Channel Making Machines

The C channel making machine is designed to manufacture these channels efficiently and with high precision. The process begins with raw material, usually in the form of flat steel sheets or coils. The machine performs a series of operations, including cutting, forming, and welding, to ultimately produce the desired C-shaped profile. Most modern machines are automated, enhancing their speed and accuracy while reducing labor costs.

Manufacturing Process In a C Channel Making Machine Factory

In a C channel making machine factory, the manufacturing process is structured to maximize productivity. Quality control is a central theme in these facilities, ensuring that every channel meets stringent industry standards. Here’s a closer look at the typical steps involved

1. Material Preparation Large coils of steel are uncoiled and fed into the machine. The preparation stage also includes checking the material for any defects.

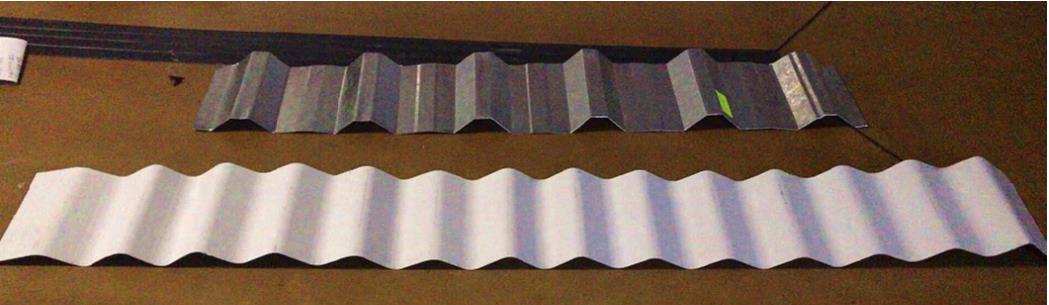

2. Cutting and Forming The flat metal sheets are cut to the required lengths. The sheets then pass through rollers that shape them into the C profile. This cold forming process is efficient and retains the material's structural integrity.

c channel making machine factory

3. Welding If a thicker channel is required, or if multiple pieces need to be joined, welding stations are employed. The welding process strengthens the channels, ensuring they can withstand considerable loads.

4. Finishing The final stage involves cleaning and surface treatments, such as galvanization or painting, to protect against corrosion and enhance durability.

5. Quality Control Throughout the process, inspections are conducted at each stage to ensure that the dimensions and properties of the channels meet specified standards.

Importance of Technology in C Channel Making

As technological advancements continue to evolve, modern C channel making machines incorporate features such as computer numerical control (CNC) systems that enhance precision and repeatability. These advancements have significantly improved production rates and reduced human error, allowing factories to produce customized orders in varying sizes and specifications.

Environmental Considerations

Today’s C channel making machine factories are also increasingly aware of their environmental footprint. Many are adopting green manufacturing practices, which include recycling scrap metal and utilizing energy-efficient technologies to reduce waste and emissions.

Conclusion

C channel making machines play a crucial role in various industries, from construction to automotive manufacturing. The factories that produce these machines are focused on efficiency, precision, and quality control, ensuring that the end products meet the diverse needs of modern construction and engineering. As technology progresses and environmental sustainability becomes more critical, these factories will continue to innovate, paving the way for more effective and eco-friendly manufacturing practices. Through the application of advanced techniques and machinery, the industry is set to evolve even further, unlocking new possibilities in construction and beyond.

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025