Top Companies Specializing in Aluminum Roll Forming Machinery Solutions

The Evolution and Importance of Aluminum Roll Forming Machine Companies

In an era where lightweight and durable materials are pivotal in various industries, aluminum has carved out a significant niche. The aluminum roll forming process plays a key role in extracting the potential of this versatile metal, offering solutions for manufacturing, automotive, construction, and many other sectors. As the demand for aluminum products grows, so does the significance of companies specializing in aluminum roll forming machines.

Understanding Roll Forming Technology

Roll forming is a continuous bending operation in which a strip of metal, usually in coil form, is fed through consecutive pairs of rollers. The rollers progressively shape the metal into the desired cross-sectional profile. This manufacturing process allows for producing long lengths of material with high precision and consistently shaped products. Aluminum roll forming, in particular, benefits from the lightweight and corrosion-resistant properties of aluminum, making it ideal for applications that require strength without adding excess weight.

The Role of Aluminum Roll Forming Machine Companies

Aluminum roll forming machine companies are at the forefront of this technology, offering equipment that enables manufacturers to optimize production efficiency. These companies design and manufacture specialized machines tailored to meet the diverse needs of industries. Whether it’s creating components for building facades, automotive parts, or custom profiles for specific applications, these machines provide the necessary precision and versatility.

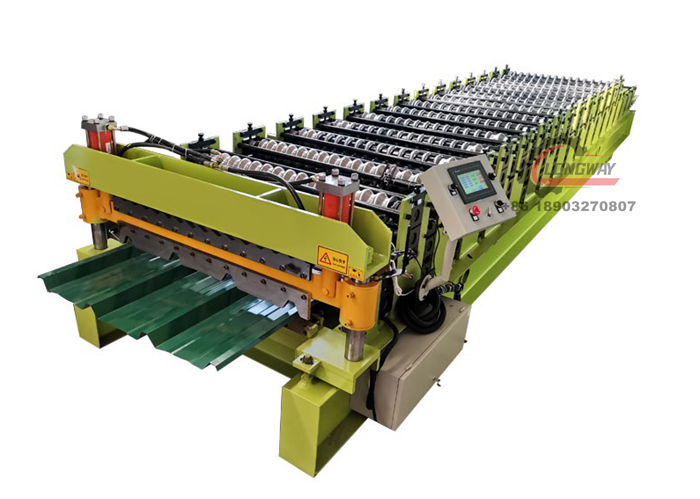

aluminum roll forming machine companies

The evolution of this technology has led to advancements that enhance automation, reduce waste, and improve the overall quality of the final product. Modern roll forming machines often incorporate features such as computer numerical control (CNC) systems, which allow for greater accuracy and the ability to quickly switch between production runs for different profiles. This adaptability is crucial in today’s fast-paced manufacturing environment where customization is often needed.

Industry Trends and Innovations

With the rise of sustainability in manufacturing practices, aluminum roll forming machine companies are also focusing on eco-friendly production methods. Using aluminum alloy, which is recyclable and requires less energy for processing than other metals, contributes to a greener environment. Furthermore, manufacturers are developing equipment that minimizes material waste, thus further enhancing the sustainability of aluminum products.

Innovations in technology, such as artificial intelligence and data analytics, are reshaping the landscape of roll forming. These advancements allow machine operators to monitor processes in real-time, identify inefficiencies, and implement improvements quickly. Predictive maintenance powered by AI can also help companies reduce downtime and extend the lifespan of their machinery.

Conclusion

As industries continue to prioritize lightweight materials and sustainable practices, aluminum roll forming machine companies are positioned to play a crucial role in meeting these demands. Their ability to produce high-quality aluminum components efficiently and sustainably will be instrumental in the growth of various sectors, from construction to automotive manufacturing. As this industry evolves, companies specializing in aluminum roll forming machines will remain at the forefront, driving innovation and shaping the future of manufacturing.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025