soffit roll forming machine manufacturer

Understanding Soffit Roll Forming Machines A Comprehensive Guide

In the manufacturing industry, efficiency and precision are paramount, especially when it comes to producing building materials. One innovative solution that has gained significant traction is the soffit roll forming machine. This article delves into what a soffit roll forming machine is, its importance in the construction sector, and key considerations when selecting a manufacturer.

What is a Soffit Roll Forming Machine?

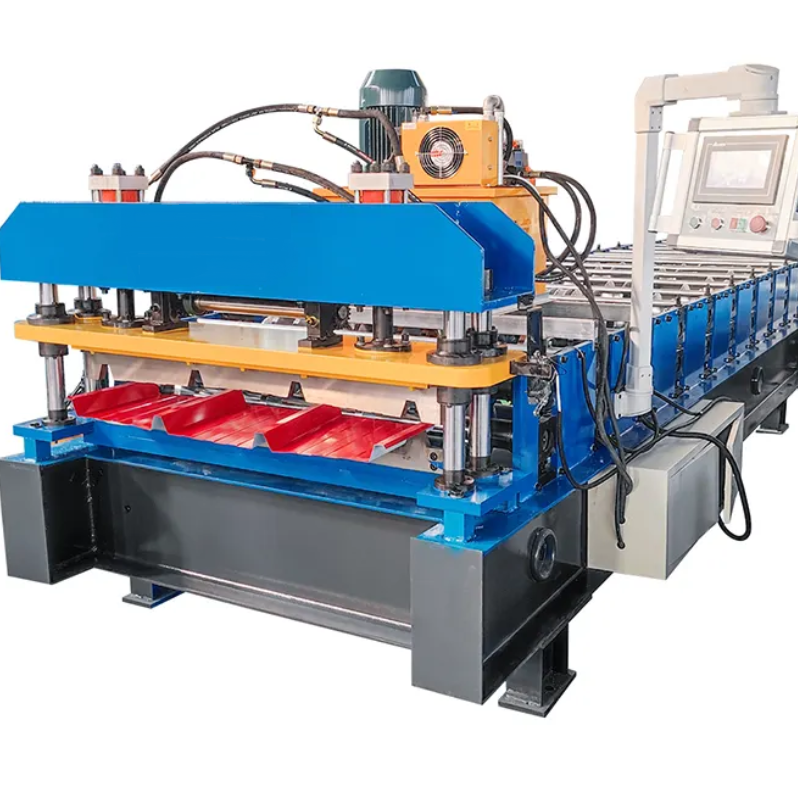

A soffit roll forming machine is designed to produce soffit panels—these are the underside surfaces of architectural features, often found under eaves or overhangs of buildings. Soffit panels are typically made from materials such as aluminum, steel, or vinyl, and serve both functional and aesthetic purposes. They improve ventilation, protect the roof structure, and enhance the overall appearance of a building.

The machine operates through a series of processes where flat metal sheets are fed into rollers that gradually shape the material into the desired profile. This process not only ensures uniformity in production but also allows for customization in terms of design and dimensions, catering to various architectural styles and client preferences.

Importance of Soffit Panels in Construction

Soffit panels play a vital role in residential and commercial construction. They contribute to the overall ventilation of attics, preventing moisture accumulation and the resulting structural damage. Furthermore, soffits can be integrated with soffit lights or ventilation systems, enhancing a building's functionality. Aesthetically, they provide a polished look that enhances the overall curb appeal of a property.

As a result, the demand for soffit roll forming machines has surged, with builders and manufacturers seeking efficient solutions to meet the needs of their clients

. A reliable soffit roll forming machine not only increases production rates but also minimizes waste, making it an attractive investment for manufacturing companies.Key Considerations When Selecting a Manufacturer

soffit roll forming machine manufacturer

When looking for a soffit roll forming machine manufacturer, several factors should be taken into account to ensure you are making a wise investment

1. Experience and Reputation Opt for manufacturers with a solid track record and good reviews in the industry. Companies with years of experience generally have a deeper understanding of the market's needs, leading to more reliable and innovative machinery.

2. Quality of Machines Assess the quality of the machines offered. Look for features like durability, precision engineering, and user-friendly controls. The manufacturing process and materials used should meet your production standards.

3. Customization Options Ensure that the manufacturer can provide tailored solutions to meet specific project requirements. The ability to customize the design and specifications of soffit panels can be a significant competitive advantage.

4. Customer Support and Training Excellent customer support is crucial, as it can significantly affect productivity. Check if the manufacturer offers training for your team, installation support, and ongoing maintenance services.

5. Technology and Innovation The manufacturing industry is continually evolving. Choose a manufacturer that embraces modern technology and innovations in roll forming, offering machinery that utilizes the latest advancements for improved efficiency and effectiveness.

6. Price and Financing While price shouldn’t be the only deciding factor, it is essential to ensure you receive good value for your investment. Compare different manufacturers and consider financing options if needed.

Conclusion

Investing in a soffit roll forming machine can greatly enhance your manufacturing capabilities, allowing you to produce high-quality soffit panels that meet the needs of your clients. By understanding what these machines do and what to look for in a manufacturer, you can make informed decisions that align with your business goals. As the demand for functional and aesthetic building solutions continues to grow, having the right equipment in place will undoubtedly position you for success in the competitive construction landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025