simple slitting line

Understanding Simple Slitting Lines A Comprehensive Overview

In the realm of metal processing, slitting lines play a pivotal role in transforming large coils of metal into narrower strips or sheets suitable for various applications. Among the different types of slitting lines available, the simple slitting line stands out for its efficiency and ease of operation. This article delves into the key aspects of simple slitting lines, including their components, operation, and significance in the manufacturing industry.

What is a Simple Slitting Line?

A simple slitting line is a system designed primarily to cut wide rolls of metal, known as coils, into narrower strips. These strips can then be used in various applications, from manufacturing automotive parts to producing packaging materials. The simplicity of the slitting line lies in its straightforward design and operation, making it an ideal choice for smaller production facilities or companies looking to enhance their processing capabilities without incurring significant costs.

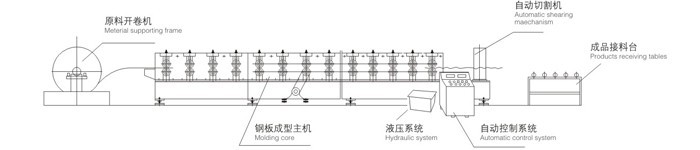

Components of a Simple Slitting Line

A simple slitting line typically consists of several critical components

1. Uncoiler This is the first station in the slitting line, where the large metal coil is mounted. The uncoiler feeds the coil into the line and is equipped with mechanisms to ensure the metal unwinds smoothly.

2. Guiding System The guiding system ensures that the metal strip remains aligned as it passes through the slitting line. Proper alignment is crucial to maintaining the quality of the finished strips.

3. Slitting Machine At the heart of the operation, the slitting machine cuts the unwound coil into the desired widths. This machine typically uses rotary blades that can be adjusted to achieve precise cuts, enabling the production of strips of varying widths.

simple slitting line

4. Re-coiler After the slitting process, the individual strips are wound onto smaller coils by the re-coiler. This station re-packages the finished strips, making them easier to handle and transport.

5. Control Panel Modern simple slitting lines often come equipped with advanced control panels that allow operators to monitor and adjust the process parameters, ensuring optimal performance.

Operation of a Simple Slitting Line

The operation of a simple slitting line is generally straightforward. Once a coil is mounted on the uncoiler, the operator sets the desired width of the final strips on the control panel. The line then automatically feeds the coil into the slitting machine, where it is cut into the specified widths by the rotating blades. As the strips are created, they are collected and wound onto the re-coiler for easy handling.

Benefits of Using a Simple Slitting Line

One of the significant advantages of a simple slitting line is its cost-effectiveness. Compared to more complex slitting systems, simple slitting lines are generally more affordable and require less maintenance. Additionally, their ease of operation makes them suitable for facilities with limited technical expertise, allowing them to produce high-quality metal strips with minimal training.

Moreover, simple slitting lines offer flexibility in operations. They can accommodate various materials, including steel, aluminum, and other metals, making them versatile tools for manufacturers in different sectors. This adaptability is crucial in a fast-paced market where requirements may change frequently.

Conclusion

In conclusion, simple slitting lines play an essential role in the metal processing industry by enabling the efficient production of narrower material strips from larger coils. With their straightforward design, ease of operation, and cost-effectiveness, they represent an attractive option for manufacturers looking to enhance their production capabilities. As the demand for specialized metal products continues to rise, the significance of simple slitting lines is likely to grow, making them a crucial component in the manufacturing landscape. Whether for small-scale operations or larger production facilities, these lines offer a practical solution for meeting the diverse needs of the industry.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025