High-Quality Sandwich Panel Roll Forming Machine Manufacturers

The Rise of Sandwich Panel Roll Forming Machines A Comprehensive Overview

In recent years, the construction industry has witnessed a growing demand for sandwich panels due to their superior insulation properties, lightweight structure, and cost-effectiveness. As a result, the need for efficient production methods has led to the rise of sandwich panel roll forming machines. These machines are essential for manufacturers looking to streamline their operations and cater to the ever-increasing demand for high-quality sandwich panels.

Understanding Sandwich Panels

Sandwich panels consist of two thin layers of metal, usually steel or aluminum, with a core of insulating material, such as polyurethane or polystyrene, sandwiched in between. This combination yields panels that are strong yet lightweight, making them ideal for various applications, including walls, roofs, and cold storage facilities. The energy efficiency of sandwich panels makes them an attractive option for businesses aiming to reduce heating and cooling costs.

The Role of Roll Forming Machines

Sandwich panel roll forming machines play a critical role in the production of these panels. These machines utilize a continuous process to shape, cut, and assemble materials into finished products. The roll forming method allows manufacturers to produce panels with precise dimensions and consistent quality, ensuring that the final output meets industry standards.

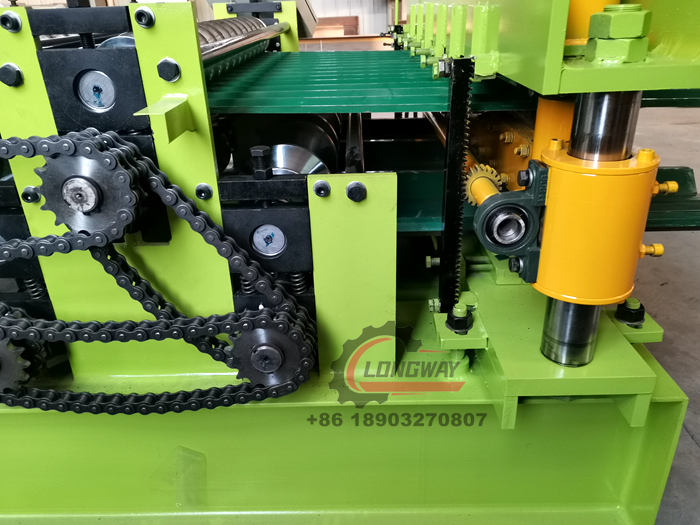

Typically, a sandwich panel roll forming machine consists of several key components, including a decoiler, forming rollers, a cutting device, and a control system. The decoiler unwinds the metal coils, while the forming rollers shape the metal into the desired profile. The cutting device then trims the panels to length, and the control system manages the overall operation, ensuring efficiency and accuracy.

Advantages of Using Sandwich Panel Roll Forming Machines

sandwich panel roll forming machine manufacturers

One of the primary advantages of using sandwich panel roll forming machines is their ability to reduce manufacturing time. The automation of the roll forming process allows for faster production rates, leading to increased output in a short time. Additionally, these machines can produce panels of varying thickness and profiles, giving manufacturers the flexibility to cater to different client needs.

Moreover, the quality of panels produced through roll forming is generally superior to that of manually produced panels. The precision involved in the roll forming process minimizes defects and inconsistencies, ensuring that each panel meets the required specifications. This quality assurance plays a crucial role in maintaining customer satisfaction and trust in a competitive market.

Key Considerations for Manufacturers

When selecting a sandwich panel roll forming machine, manufacturers must consider several factors. These include the machine's production capacity, the range of profiles it can produce, and its energy efficiency. Investing in a machine with advanced technology and features can enhance productivity and ultimately lead to better profit margins.

Furthermore, the expertise of the manufacturer is essential. Companies should seek out experienced sandwich panel roll forming machine manufacturers who offer not only reliable equipment but also robust after-sales support, including installation, maintenance, and training for operators.

Conclusion

In conclusion, the rise in demand for sandwich panels has significantly influenced the manufacturing landscape, leading to the increased adoption of sandwich panel roll forming machines. These machines offer various advantages, including improved efficiency, consistent quality, and flexibility in production. As the construction industry continues to evolve, manufacturers equipped with advanced roll forming technology will be at the forefront of innovation, contributing to the sustainability and energy efficiency of modern buildings.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025