rack roll forming machine

Rack Roll Forming Machine An Overview

In the world of modern manufacturing, efficiency and precision are paramount. One innovation that has significantly enhanced these two aspects is the rack roll forming machine. This sophisticated equipment is designed to create various types of rack structures often used in warehouses, industrial settings, and even residential storage solutions. By utilizing advanced roll forming technology, this machine streamlines the production of high-quality racks, ensuring that businesses can meet their storage needs effectively.

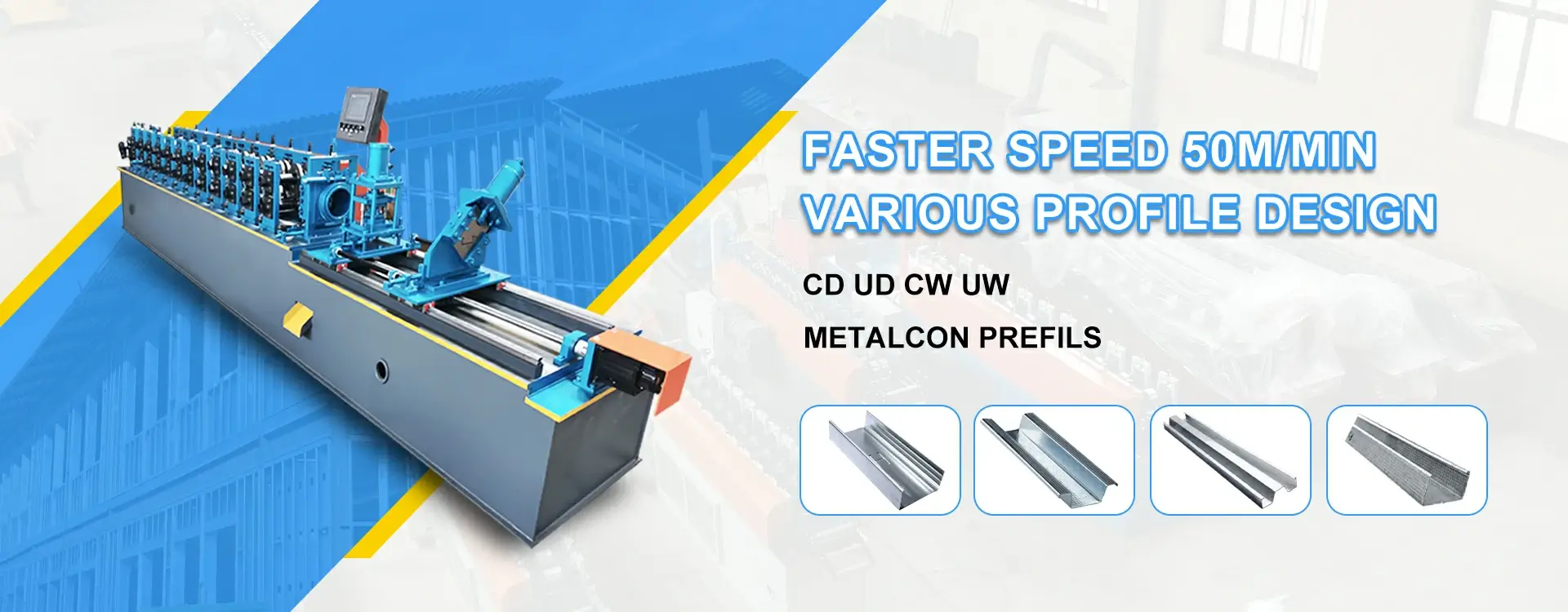

At its core, a rack roll forming machine operates by continuously bending and shaping flat metal sheets into the desired rack profiles. The process begins with a coiled sheet of metal, which is fed into the machine. A series of rollers, each designed to perform a specific bending action, gradually shape the metal into a pre-defined form. This continuous process allows for high-volume production with minimal waste, making it both cost-effective and environmentally friendly.

One of the significant advantages of using a rack roll forming machine is the ability to produce racks that meet specific requirements. Businesses can customize their rack dimensions and designs according to their storage needs, which is essential in optimizing space utilization. For instance, adjustable shelves can be created to accommodate various sized items, thereby improving operational efficiency.

rack roll forming machine

Moreover, the durability of racks produced by roll forming machines is another crucial factor. The manufacturing process ensures that metal is not only shaped but also retains its strength. High-quality steel is often used, which provides the rack with enhanced load-bearing capabilities. This durability translates into long-term reliability, reducing the need for replacements and repairs. As a result, businesses experience lower operational costs over time.

Another critical feature of rack roll forming machines is their versatility. These machines can be adapted to produce a range of rack types, including selective racks, pallet racks, and cantilever racks. This adaptability makes it possible for manufacturers to cater to diverse industries, from logistics and retail to manufacturing and construction. By providing tailored solutions, they can meet the specific demands of various sectors, ensuring customer satisfaction.

In addition, the technological advancements in roll forming machines have made them increasingly user-friendly. Many modern machines come equipped with digital controls that allow operators to quickly change specifications and monitor production processes in real-time. This innovation not only enhances operational efficiency but also reduces the likelihood of human error.

In conclusion, the rack roll forming machine is an essential piece of equipment in contemporary manufacturing. Its ability to produce customized, durable, and efficient storage solutions makes it invaluable for various industries. As businesses continue to seek innovative ways to optimize their operations and space, the demand for rack roll forming machines is likely to grow, further solidifying their role in the future of manufacturing.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025