guardrail roll forming machine manufacturers manufacturer

Understanding the Role of Guardrail Roll Forming Machine Manufacturers

In today's fast-paced world, the construction and infrastructure industries are continually searching for efficient and high-quality manufacturing processes. One critical component in roadway safety is the guardrail, which helps protect vehicles and pedestrians from accidents and hazards. The production of these guardrails involves specialized machinery known as guardrail roll forming machines. This article delves into the significance of manufacturers in this niche industry, their production processes, and the innovative technologies they employ.

What is a Guardrail Roll Forming Machine?

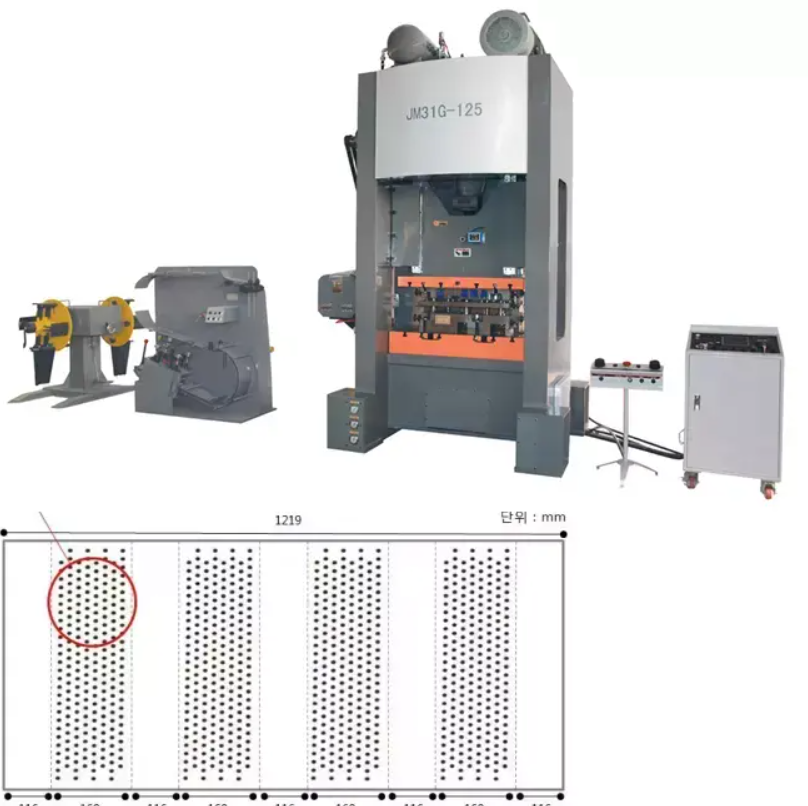

A guardrail roll forming machine is a type of equipment specifically designed to shape and fabricate guardrails from metal sheets. The machine uses a continuous forming process that involves feeding coils of metal through a series of rollers. These rollers gradually shape the metal into the desired profile—typically U-shaped or W-beamed guardrails that are known for their strength and durability.

This machinery is vital for producing guardrails that meet strict safety standards. The roll forming process is advantageous due to its efficiency and the lower material waste it generates compared to traditional metalworking methods like stamping or cutting.

The Role of Manufacturers

Guardrail roll forming machine manufacturers play a crucial role in the safety and infrastructure landscape. They are responsible for producing and providing high-quality machines that meet various operational needs, from small businesses to large-scale manufacturers.

1. Customization and Innovation Recognizing the diverse requirements across markets, many manufacturers offer customized solutions. This can range from the specific dimensions of the guardrails to the materials used. Innovative manufacturers integrate the latest technologies, such as automation and smart controls, into their machines, improving operational efficiency and reducing manual labor.

2. Quality Control Quality assurance is paramount in guardrail production. Reliable manufacturers adhere to international standards, ensuring that their machines produce consistently high-quality guardrails. Rigorous testing and monitoring processes are implemented to detect any deviations from standard specifications.

3. Technical Support and Maintenance Manufacturers not only supply the machinery but also provide crucial after-sales support. This includes installation services, operator training, and ongoing maintenance. By offering a comprehensive support system, manufacturers help ensure that their customers can maximize the productivity and longevity of their equipment.

guardrail roll forming machine manufacturers manufacturer

Advancements in Technology

Technology plays a significant role in the evolution of guardrail roll forming machines. Recent advancements include

- Automation Automated systems enhance operational efficiency by minimizing human intervention. This includes automated feeding, cutting, and stacking of finished products, which significantly increases production speed. - CNC (Computer Numerical Control) CNC technology allows for precise control over the shaping process, enabling intricate designs and high-quality outcomes that meet regulatory standards.

- Energy Efficiency Many modern machines are designed to utilize energy more effectively, reducing operational costs and environmental impact.

Global Market Trends

The demand for guardrail roll forming machines is rising globally due to increased investments in infrastructure and road safety. Countries experiencing rapid urbanization are particularly driving this demand. As road networks expand, the need for effective vehicle safety measures, including guardrails, is more pressing than ever.

Moreover, as awareness grows regarding the importance of road safety, manufacturers are expected to innovate further, creating machines that produce not just traditional guardrails but also advanced safety features and designs. Additionally, the shift toward sustainable materials in construction means that future machines may need to accommodate different types of metals and composite materials.

Conclusion

Guardrail roll forming machine manufacturers are integral to ensuring safety on our roads. By constantly innovating and adapting to changing market needs, they play a pivotal role in the construction and infrastructure industries. As road safety becomes increasingly critical, the demand for high-quality guardrails produced by advanced machinery will undoubtedly grow. Investing in quality machinery not only enhances production efficiency but also contributes to safer road environments for all users. The collaboration between manufacturers and clients will ultimately pave the way for even higher safety standards and innovative solutions in the future.

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025