double layer roll forming machine for roof

Double Layer Roll Forming Machine for Roof An In-Depth Overview

In the realm of modern construction and manufacturing, the efficiency of materials and processes is paramount. Among the innovative technologies that have evolved to enhance productivity and quality in building infrastructure is the double layer roll forming machine. Specifically designed for roof applications, this machine offers significant advantages in terms of versatility and efficiency.

What is a Double Layer Roll Forming Machine?

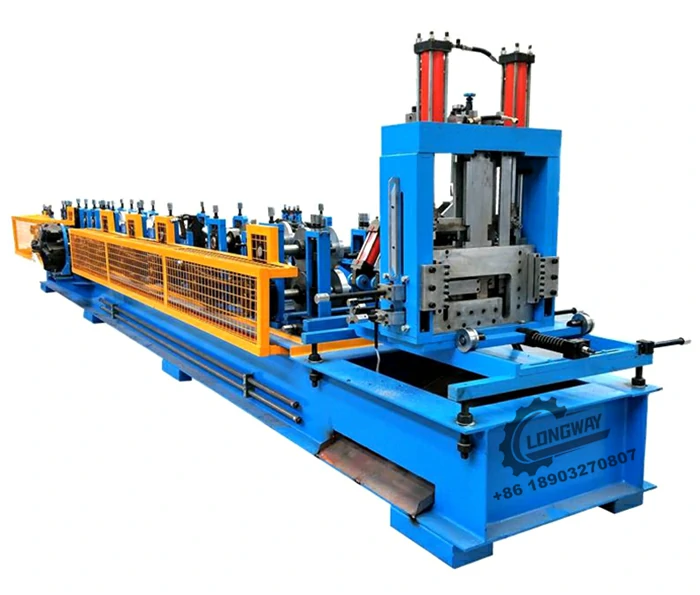

A double layer roll forming machine is an advanced piece of equipment that can produce two different profiles of roof panels from a single machine by using different rolls and settings. This innovative solution is particularly beneficial in projects where space, resources, and time are limited. By integrating two production lines into one machine, manufacturers can save on initial investments and reduce the amount of physical space needed for operations.

The machine typically consists of a frame, feeding system, roll forming system, cutting system, and control system. The rolls are designed in such a way that they can switch between producing two distinct sheet profiles, such as corrugated and tile pattern roofing sheets, without extensive downtime.

The Advantages of Using a Double Layer Roll Forming Machine

1. Space Efficiency One of the primary benefits of a double layer roll forming machine is its compact design, which requires less floor space compared to having two separate machines. In crowded manufacturing environments, this can lead to better space utilization and a more organized workspace.

2. Cost-Effective By consolidating the functions of two machines into one, manufacturers can significantly reduce their capital investment. Additionally, maintenance costs also decrease since they only need to manage a single piece of equipment.

3. Increased Productivity The ability to switch between different product types without the need for extensive setup changes allows manufacturers to respond quickly to varying market demands. This adaptability can lead to increased output and reduced turnaround times.

4. Minimized Waste Since the double layer roll forming machine operates more efficiently, it leads to reduced material waste. This not only benefits the environment but also helps in lowering material costs, making production more economical.

double layer roll forming machine for roof

5. Quality Control With advanced automated controls and consistent roll forming processes, manufacturers can ensure high-quality outputs. The precision offered by these machines minimizes defects and inconsistencies in the final products.

Applications of Double Layer Roof Panels

The panels produced by double layer roll forming machines can be used in a variety of applications. They are ideal for residential, commercial, and industrial roofing projects. The flexibility to produce different styles and profiles means that manufacturers can cater to a wide range of customer preferences and architectural designs.

Common applications include

- Residential Roofing Many homeowners are looking for durable, aesthetically pleasing options for their roofs. Double-layer panels provide both beauty and function, with profiles that mimic traditional roofing materials while offering superior durability.

- Commercial Buildings For commercial applications, the efficiency of construction and reliable performance under various environmental conditions are critical. Double layer panels can provide excellent weather resistance, thermal efficiency, and structural integrity.

- Industrial Structures In industrial settings where longevity and resistance to harsh conditions are paramount, the versatility of double layer panels ensures that buildings are both functional and cost-effective.

Conclusion

In conclusion, the double layer roll forming machine for roof panel production represents a significant advancement in manufacturing technology for the construction industry. Its ability to efficiently produce multiple roofing profiles from a single machine not only saves space and costs but also enhances productivity and quality. As the demand for versatile and efficient building materials continues to grow, the double layer roll forming machine is poised to play a key role in shaping the future of roofing solutions. By adopting this technology, manufacturers can meet the evolving needs of their clientele, ensuring that they remain competitive in a dynamic market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025