Manufacturer of Machines for Producing Corrugated Sheets Efficiently and Effectively

The Evolution and Significance of Corrugated Sheet Making Machines

In the modern manufacturing landscape, corrugated sheet making machines have emerged as essential tools for producing lightweight, strong, and durable packaging solutions. The corrugated sheet is widely used in various industries, especially for packaging, where its ability to provide structural support and protect products during transit is invaluable. This article delves into the importance of corrugated sheet making machines, the manufacturing process, and the leading manufacturers in the field.

What is a Corrugated Sheet Making Machine?

A corrugated sheet making machine is a specialized piece of equipment designed to produce corrugated cardboard sheets by combining layers of paperboard in a way that provides optimal strength and flexibility. The machine typically involves a feeder, a flute forming section, an adhesive application unit, and a drying or curing section. This process not only enables the production of sheets of various sizes and strengths but also facilitates the integration of custom designs and printing on the sheets, catering to specific client needs.

The Manufacturing Process

The production of corrugated sheets generally consists of three main components the linerboard and the medium (the fluted paper). The linerboards are produced from recycled paper or virgin fibers, while the medium function is to provide the structural integrity that allows the sheet to withstand various stresses.

1. Preparation of Raw Materials The process begins with sourcing high-quality paper from suppliers. Manufacturers typically prefer materials that provide optimal stiffness and smoothness, which are essential for effective printing and handling.

2. Flute Formation The heart of the corrugated sheet making process is the flute formation. The medium paper is heated and shaped into a wavy or fluted structure, which is what gives corrugated cardboard its distinctive strength and flexibility.

3. Adhesive Application Once the flute is formed, it must be adhered to the linerboard. This is typically achieved through the application of specialized adhesives that are designed to withstand various environmental factors.

4. Curing and Drying After the sheets are assembled, they pass through a drying section to ensure that the adhesives set properly. This step is crucial in ensuring that the final product can withstand the rigors of packaging and transportation.

5. Cutting and Finishing The final product is cut into specified dimensions based on customer requirements, and additional features may be added, such as custom printing or die cuts.

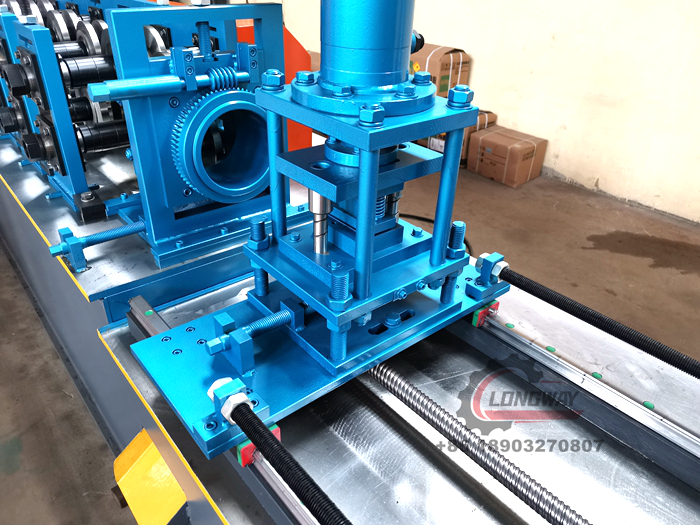

corrugated sheet making machine manufacturer

Significance in Various Industries

The versatility of corrugated sheets has made them indispensable in numerous sectors. In the shipping and logistics industries, they serve as superior protective packaging for fragile goods. E-commerce companies rely heavily on corrugated cardboard for shipping their products efficiently while ensuring they arrive undamaged. Additionally, the food and beverage industry uses corrugated sheets for packaging perishables, ensuring freshness while maintaining a sustainable packaging approach.

Beyond packaging, corrugated sheets are also utilized in the construction industry for temporary structures and insulation, showcasing their adaptability.

Choosing the Right Manufacturer

When it comes to selecting a corrugated sheet making machine manufacturer, several factors should be considered

- Experience and Reputation It's vital to opt for manufacturers with a proven track record in delivering high-quality machines.

- Technology and Innovation Advanced technology enhances productivity and precision. Manufacturers who invest in R&D are often at the forefront of quality and efficiency.

- Customization Many businesses require specific solutions for their packaging needs. A manufacturer that offers customized machinery can better cater to those unique requirements.

- After-Sales Support Reliable after-sales support ensures that businesses can maintain their machines efficiently, minimizing downtime.

Conclusion

The importance of corrugated sheet making machines cannot be overstated in today's manufacturing ecosystem. They play a crucial role in producing sustainable packaging solutions that align with modern business needs, emphasizing efficiency and environmental responsibility. As industries continue to evolve, the manufacturers of these machines will remain vital in ensuring that businesses have access to innovative and high-quality corrugated solutions for their packaging needs. By investing in the right technology and working closely with reputable manufacturers, companies can enhance their production capabilities and respond more effectively to market demands.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025