China Cold Roll Forming Equipment Manufacturer for High-Quality Metal Production Solutions

An Overview of China's Cold Roll Forming Machine Industry

In recent years, China's manufacturing sector has witnessed significant growth, particularly in the area of cold roll forming machines. These machines are integral in creating various metal products used in construction, automotive, and other industries. Cold roll forming is a process that involves shaping metal into desired cross-sections at room temperature, which offers numerous advantages such as improved strength, better surface quality, and reduced material wastage. This article explores the characteristics, applications, and advancements in China's cold roll forming machine manufacturing.

The Characteristics of Cold Roll Forming Machines

Cold roll forming machines operate by continuously bending a metal strip or sheet into a specific profile. The process typically involves several rollers that progressively shape the metal, ensuring it retains its structural integrity. One of the primary characteristics of these machines is their ability to produce complex sections with intricate designs. This flexibility allows manufacturers to cater to a diverse range of industries, from construction to automotive.

China's cold roll forming machines are recognized for their high efficiency and precision. The advanced technology integrates computerized systems that provide real-time data and quality control throughout the production process. Moreover, modern machines are designed to be energy-efficient, aligning with global trends toward sustainability and minimal environmental impact.

Applications in Various Industries

The versatility of cold roll forming machines enables their use in a multitude of applications. In the construction sector, they are employed to manufacture steel frames, roofing, and siding materials. The construction of buildings, bridges, and other infrastructures often relies on the strength and durability of products produced through roll forming.

In the automotive industry, cold roll forming is critical for producing components such as support frames, brackets, and other structural elements. The lightweight yet robust nature of roll-formed parts contributes to fuel efficiency and safety standards in modern vehicles. Furthermore, the rapid production times and customizability of these machines make them an attractive option for manufacturers looking to meet the demands of a dynamic market.

Technological Advancements

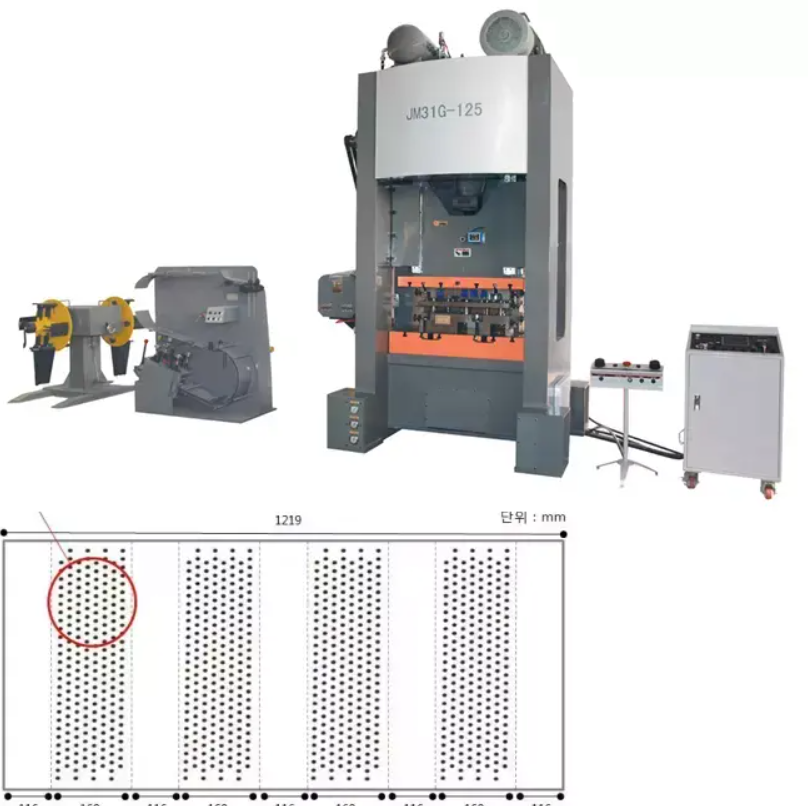

china cold roll forming machine factory

China's cold roll forming machine factories are at the forefront of technological advancements. Research and development have led to innovations such as the integration of automation and machine learning. These technologies enhance production efficiency by minimizing downtime, reducing labor costs, and improving overall product quality.

Additionally, manufacturers are increasingly adopting Industry 4.0 principles, which incorporate smart technology into the production process. This includes the use of IoT devices to monitor machine performance and predictive maintenance to prevent breakdowns. The implementation of such technologies not only improves efficiency but also allows for greater customization to meet specific client requirements.

Global Competitiveness

China's cold roll forming machine industry has become a significant player in the global market. The country's ability to produce high-quality machines at competitive prices has attracted customers from around the world. Chinese manufacturers are continuously improving their production techniques and focusing on quality assurance to maintain their edge in the international arena.

Moreover, the government's initiatives to support the manufacturing sector, including investments in technology and export incentives, have further facilitated the growth of this industry. As a result, China has positioned itself as a reliable source for cold roll forming machines and components.

Challenges and Future Prospects

Despite its growth and advancements, the cold roll forming machine industry in China faces challenges. The increasing demand for high-quality standards and environmental regulations necessitates continuous improvements in processes and technologies. Manufacturers must stay abreast of global trends and customer demands to sustain their competitive advantage.

Looking ahead, the prospects for China's cold roll forming machine industry remain positive. The ongoing expansion of urbanization and infrastructure development presents ample opportunities for growth. Furthermore, as industries shift toward more sustainable practices, the demand for energy-efficient forming solutions will continue to rise.

In conclusion, China's cold roll forming machine industry plays a vital role in the global manufacturing landscape. With its blend of advanced technology, diverse applications, and a commitment to quality, the industry is well-positioned for sustained growth. As manufacturers navigate challenges and embrace innovation, the future of cold roll forming in China appears promising, reinforcing the country's status as a manufacturing powerhouse.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025