Nouvelles

-

Roll Former offers the most productive and cost-effective roll forming equipment for the metal roofing and architectural sheet metal industries. Since 1978 we have been leading the industry with our innovations and service.En savoir plus

Roll Former offers the most productive and cost-effective roll forming equipment for the metal roofing and architectural sheet metal industries. Since 1978 we have been leading the industry with our innovations and service.En savoir plus -

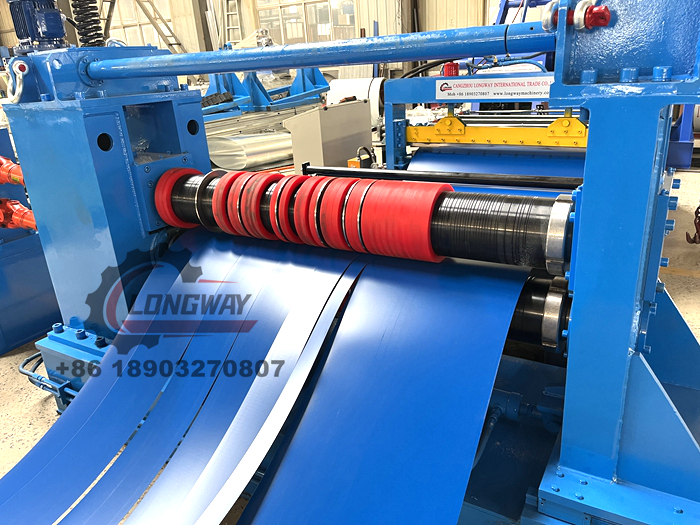

Roll forming, also known as roll-forming or rollforming, is a type of rolling involving the continuous bending of a long strip of sheet metal (typically coiled steel) into a desired cross-section. The strip passes through sets of rolls mounted on consecutive stands, each set performing only an incremental part of the bend, until the desired cross-section (profile) is obtained. Roll forming is ideal for producing constant-profile parts with long lengths and in large quantities.En savoir plus

Roll forming, also known as roll-forming or rollforming, is a type of rolling involving the continuous bending of a long strip of sheet metal (typically coiled steel) into a desired cross-section. The strip passes through sets of rolls mounted on consecutive stands, each set performing only an incremental part of the bend, until the desired cross-section (profile) is obtained. Roll forming is ideal for producing constant-profile parts with long lengths and in large quantities.En savoir plus -

Metal rollforming might not be as simple as you may think; machines can come in a variety of sizes, product outputs, uses, speeds, and more. Before you buy, make sure you’re educated on the background and importance of metal rollforming in today’s industry.En savoir plus

Metal rollforming might not be as simple as you may think; machines can come in a variety of sizes, product outputs, uses, speeds, and more. Before you buy, make sure you’re educated on the background and importance of metal rollforming in today’s industry.En savoir plus -

AMS Controls’ core business is machine control and production management for roll forming industries. As such, length control is a primary focus, so we wanted to produce a series of articles on issues that can cause length variance– where problems come from, and how to eliminate them. Once we got past encoder issues (which are common across all machine types), we wanted to tackle length control based on machine application – non-stop vs. stopping, servo control vs. non-servo control.En savoir plus

AMS Controls’ core business is machine control and production management for roll forming industries. As such, length control is a primary focus, so we wanted to produce a series of articles on issues that can cause length variance– where problems come from, and how to eliminate them. Once we got past encoder issues (which are common across all machine types), we wanted to tackle length control based on machine application – non-stop vs. stopping, servo control vs. non-servo control.En savoir plus -

The following article is based in part on “Justification for roll forming,” prepared for the FABTECH conference by Brian Rodgers, senior application engineer, Formtek Inc.En savoir plus

The following article is based in part on “Justification for roll forming,” prepared for the FABTECH conference by Brian Rodgers, senior application engineer, Formtek Inc.En savoir plus -

Rolling is a forming process which reduces the cross-sectional area of the incoming metal stock or produces a new cross-section of the material at the exit while improving its mechanical properties through the use of rotating rolls.En savoir plus

Rolling is a forming process which reduces the cross-sectional area of the incoming metal stock or produces a new cross-section of the material at the exit while improving its mechanical properties through the use of rotating rolls.En savoir plus -

Last week, we detailed the advantages of press braking, comparing it to roll forming as a metal fabrication bending process. Although they have little in common, other than the process category, both are important and have many uses. More than anything, choosing one over the other depends mainly on the end product undergoing fabrication. This week, we’ll take a look at closer look at roll forming specifically.En savoir plus

Last week, we detailed the advantages of press braking, comparing it to roll forming as a metal fabrication bending process. Although they have little in common, other than the process category, both are important and have many uses. More than anything, choosing one over the other depends mainly on the end product undergoing fabrication. This week, we’ll take a look at closer look at roll forming specifically.En savoir plus -

Even design engineers with 20+ years of experience still Google this question. Despite its efficient and industrious nature, roll forming is a niche manufacturing process known to few and understood by even fewer.En savoir plus

Even design engineers with 20+ years of experience still Google this question. Despite its efficient and industrious nature, roll forming is a niche manufacturing process known to few and understood by even fewer.En savoir plus -

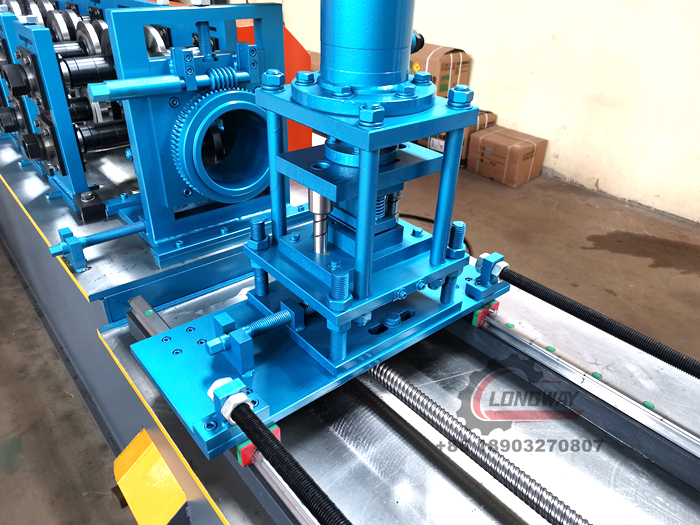

A roll former may appear to be a complex machine, with its array of stations and high speeds. It’s worth learning about how it works because it can perform a unique function and create identical end products consistently that meet the strictest of specifications.En savoir plus

A roll former may appear to be a complex machine, with its array of stations and high speeds. It’s worth learning about how it works because it can perform a unique function and create identical end products consistently that meet the strictest of specifications.En savoir plus -

The roll forming process is a metal-forming operation that imparts the desired shape to a material strip in a progressive manner.En savoir plus

The roll forming process is a metal-forming operation that imparts the desired shape to a material strip in a progressive manner.En savoir plus -

The desired cross section is gradually formed as it passes through the rollers. The material starts as a flat coil or blank and each pair of rolls adds to the shape.En savoir plus

The desired cross section is gradually formed as it passes through the rollers. The material starts as a flat coil or blank and each pair of rolls adds to the shape.En savoir plus -

There are several advantages of using roll forming for your projects:En savoir plus

There are several advantages of using roll forming for your projects:En savoir plus