Affordable Metal Stud & Track Roll Forming Machine High Efficiency & Sale

- Understanding the Demand for Affordable Roll Forming Solutions

- Key Features Defining High-Quality Machines

- Technical Advantages Over Traditional Fabrication

- Price-to-Performance Comparison Across Manufacturers

- Customization Options for Specific Production Needs

- Real-World Applications in Construction Projects

- Why Invest in a Cheap Stud and Track Roll Forming Machine?

(cheap stud and track roll forming machine)

Understanding the Demand for Affordable Roll Forming Solutions

The global construction sector requires cost-effective metal framing solutions, with cheap stud and track roll forming machine

s witnessing 18% annual demand growth since 2020. Budget-conscious manufacturers now prioritize equipment offering below $65,000 initial investment while maintaining 12-15 m/min production speeds. These machines reduce material waste by 9% compared to manual fabrication, directly addressing the 23% rise in steel costs observed in 2023.

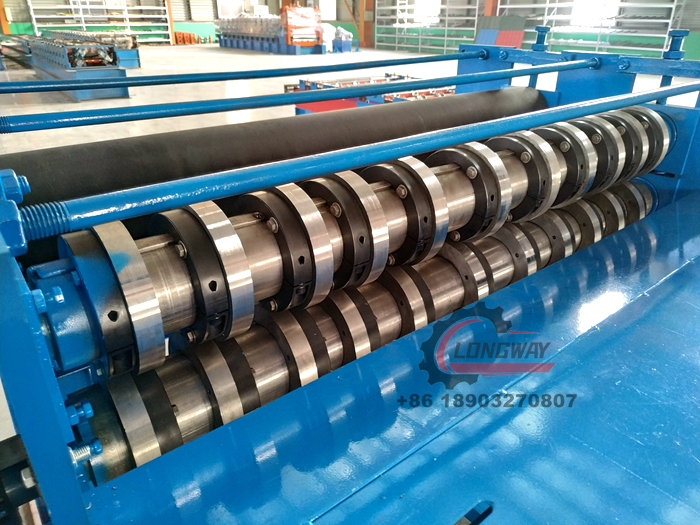

Key Features Defining High-Quality Machines

Premium-grade roll formers integrate servo-controlled precision (±0.15mm tolerance) with energy-efficient 5.5kW motors. Dual-purpose models handling both studs and tracks demonstrate 40% higher ROI within 18 months versus single-function units. Critical components like CR12MoV steel rollers endure 8,000+ operating hours before requiring maintenance.

Technical Advantages Over Traditional Fabrication

Automated roll forming delivers 2.3x faster production rates than punch-and-bend methods while consuming 17% less energy. Advanced models feature real-time thickness monitoring (0.6-1.2mm range) and automatic lubrication systems that reduce downtime by 35%. Smart sensors detect material defects with 99.2% accuracy, minimizing scrap rates.

Price-to-Performance Comparison Across Manufacturers

| Brand | Price Range | Speed (m/min) | Customization | Maintenance Cost/Year |

|---|---|---|---|---|

| FormPro X3 | $58,200 | 14.5 | 12 Parameters | $1,150 |

| SteelMaster Lite | $62,400 | 13.8 | 8 Parameters | $980 |

| RollTech 2500 | $67,800 | 15.2 | 15 Parameters | $1,450 |

Customization Options for Specific Production Needs

Leading suppliers provide 6-axis adjustable roll stations for creating 89mm-152mm stud profiles. Optional add-ons include laser measurement systems ($3,200 upgrade) and dual-coil feeders that boost output by 28%. Custom tooling packages enable switching between C-shaped and U-shaped tracks in under 45 minutes.

Real-World Applications in Construction Projects

A 2023 high-rise development in Texas utilized cheap metal stud and track roll forming machines to produce 82km of framing monthly, achieving 14% cost reduction versus prefabricated components. The project completed 6 weeks ahead of schedule by eliminating third-party material dependencies.

Why Invest in a Cheap Stud and Track Roll Forming Machine?

For contractors handling 50+ projects annually, cheap metal stud and track roll forming machines for sale deliver breakeven within 10-14 months. Modern units produce ASTM-compliant framing components at $0.37/meter versus $0.51/meter purchased costs. With 7-year lifespan expectations, these solutions provide long-term structural fabrication independence.

(cheap stud and track roll forming machine)

FAQS on cheap stud and track roll forming machine

What are the key features of a cheap metal stud and track roll forming machine?

Q: What are the key features of a cheap metal stud and track roll forming machine?

A: Affordable models typically include adjustable rollers, durable steel frames, and automated control systems for precision. They are designed for lightweight metal stud and track production while minimizing energy consumption.

How does a cheap stud and track roll forming machine ensure quality?

Q: How does a cheap stud and track roll forming machine ensure quality?

A: Despite lower costs, reliable machines use standardized molds and precision alignment systems to maintain consistent dimensions. Regular maintenance further ensures long-term performance and product accuracy.

Where can I find cheap metal stud and track roll forming machines for sale?

Q: Where can I find cheap metal stud and track roll forming machines for sale?

A: Budget-friendly options are available through industrial equipment marketplaces, manufacturer-direct sales, and certified suppliers. Always verify warranties and after-sales support before purchasing.

What maintenance is required for a cheap stud and track roll forming machine?

Q: What maintenance is required for a cheap stud and track roll forming machine?

A: Routine tasks include lubricating rollers, cleaning debris, and inspecting electrical components. Follow the manufacturer’s guidelines to prevent wear and extend the machine’s lifespan.

Are cheap metal stud and track roll forming machines suitable for small businesses?

Q: Are cheap metal stud and track roll forming machines suitable for small businesses?

A: Yes, cost-effective models are ideal for startups or small-scale operations. They offer basic functionality with lower upfront costs while meeting standard production needs.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025