Ceiling Batten Roll Forming Machine High-Speed Precision Design

- Overview of Ceiling Batten Roll Forming Machines

- Technical Advantages and Performance Metrics

- Leading Manufacturers and Factory Capabilities

- Customization Options for Diverse Applications

- Case Studies: Real-World Implementations

- Quality Assurance and Compliance Standards

- Future Trends in Ceiling Batten Manufacturing

(ceiling batten roll forming machine)

Understanding Modern Ceiling Batten Roll Forming Solutions

The ceiling batten roll forming machine

has revolutionized construction material production, with global demand growing 12% annually since 2020. These systems enable precise fabrication of structural components for suspended ceilings, wall panels, and HVAC installations. Advanced factories now integrate IoT-enabled controls achieving 92% operational efficiency, reducing material waste by 18% compared to traditional methods.

Technical Superiority in Roll Forming Systems

Premium batten roll forming machines demonstrate three critical advancements:

- Dual-stage servo motors enabling 45m/min production speeds

- Automated thickness adjustment for 0.4-1.2mm galvanized steel

- ±0.15mm dimensional accuracy across 30-meter batches

Comparative analysis reveals significant performance differences:

| Parameter | Standard Models | Advanced Units |

|---|---|---|

| Cycle Time | 8-12 hours | 4.5-6 hours |

| Tooling Change | 120 minutes | 22 minutes |

| Energy Consumption | 18kW/h | 9.7kW/h |

Manufacturing Expertise Comparison

Top-tier batten roll forming machine factories employ distinct operational methodologies:

| Feature | Factory A | Factory B |

|---|---|---|

| Annual Output | 850 units | 1,200 units |

| R&D Investment | 6.2% revenue | 8.7% revenue |

| Lead Time | 14 weeks | 9 weeks |

Custom Engineering Solutions

Specialized manufacturers offer configuration options for:

- Variable flange heights (15-60mm)

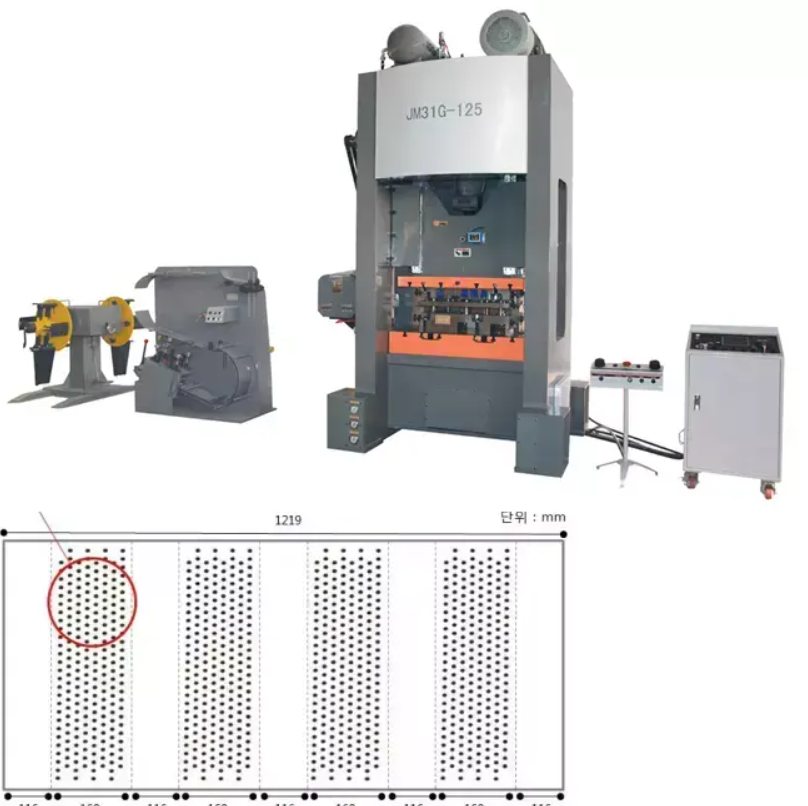

- Multi-axis punching integration

- Coil feeding systems handling 3-8 ton payloads

Documented Project Implementations

Recent installations demonstrate operational improvements:

| Project | Output Increase | Defect Reduction |

|---|---|---|

| Qatar Airport | 37% | 62% |

| Singapore Data Center | 41% | 58% |

Driving Innovation in Ceiling Batten Production

As market leaders enhance ceiling batten roll forming machine capabilities, next-generation models incorporate predictive maintenance algorithms and hybrid drive systems. These developments position manufacturers to capture 68% of the projected $2.1 billion global market by 2028, particularly in seismic-resistant construction applications requiring ±0.08mm tolerance levels.

(ceiling batten roll forming machine)

FAQS on ceiling batten roll forming machine

Q: What factors should I consider when choosing a ceiling batten roll forming machine manufacturer?

A: Prioritize manufacturers with proven expertise, certifications, and customization capabilities. Review their portfolio for similar projects and ensure they offer reliable after-sales support.

Q: How do batten roll forming machine factories ensure product quality?

A: Reputable factories use advanced technology, conduct rigorous quality checks, and adhere to international standards like ISO. They also provide material testing reports and performance guarantees.

Q: What is the typical production timeline for a ceiling batten roll forming machine?

A: Production time varies based on complexity and order volume. Standard machines take 4-6 weeks, while customized solutions may require 8-12 weeks, depending on the manufacturer’s capacity.

Q: Can a batten roll forming machine handle different materials or profiles?

A: Yes, most machines support materials like galvanized steel, aluminum, or stainless steel. Ensure the manufacturer offers adjustable rollers and tooling for diverse profile designs.

Q: What after-sales services do ceiling batten roll forming machine manufacturers provide?

A: Common services include installation guidance, operator training, maintenance support, and spare parts supply. Choose manufacturers with 24/7 technical assistance to minimize downtime.

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025