z shape roll forming purling machine

Z Shape Roll Forming Purlin Machine A Comprehensive Overview

In the modern construction industry, the demand for efficient and cost-effective structural components has led to the development of advanced manufacturing technologies. One such innovation is the Z shape roll forming purlin machine, which plays a vital role in producing Z-shaped purlins that are widely utilized in various construction applications.

Understanding Z Shape Purlins

Z shape purlins are structural steel members that are primarily used to support roof and wall cladding systems. Unlike traditional C purlins, the Z configuration allows for a more efficient overlap during construction, leading to enhanced structural integrity. These purlins are particularly favored in building frameworks due to their high load-bearing capacity and lightweight nature. They are commonly used in agricultural buildings, warehouses, and industrial sheds.

The Roll Forming Process

The roll forming process is a continuous bending operation in which a long strip of sheet metal, often steel, is gradually shaped into the desired profile using a series of paired rollers. The Z shape roll forming machine is specifically designed to produce purlins with precise dimensions and excellent surface finish. The process begins with a flat steel coil that is fed into the machine. As it passes through multiple sets of rollers, the steel is progressively shaped into a Z profile. This automated process is not only efficient but also minimizes material waste, which is a critical factor in sustainable manufacturing practices.

Key Components of the Machine

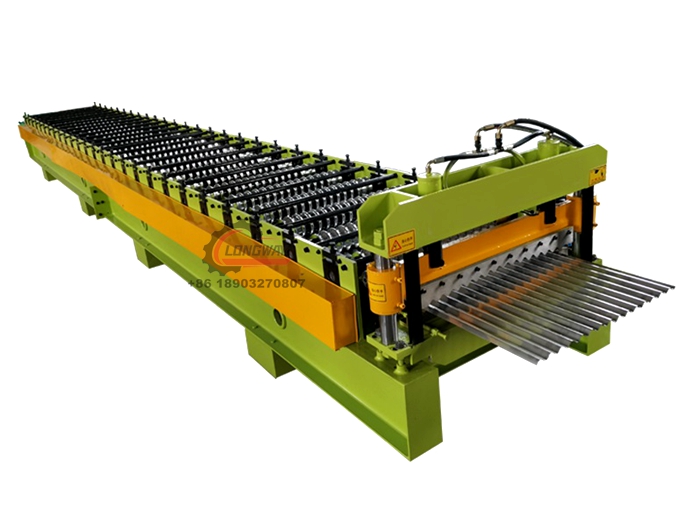

z shape roll forming purling machine

A typical Z shape roll forming machine consists of several essential components

1. Feeding System This mechanism ensures the consistent feeding of the steel coil into the roller system. 2. Rolls The key component of the machine, the rollers are meticulously designed to form the steel into the required Z shape. Each set of rollers is tailored to achieve specific dimensions and profiles. 3. Cutting Mechanism After the steel has been formed into the desired shape, it is cut to the specified lengths. This can be done using a hydraulic or mechanical cutting system. 4. Control System Modern machines are equipped with digital control panels that allow operators to set and monitor parameters such as speed, length, and roll pressure, ensuring high accuracy in production.

Benefits of Z Shape Roll Forming Machines

The adoption of Z shape roll forming machines offers numerous advantages. Firstly, they provide high production efficiency, allowing manufacturers to produce large quantities of purlins in a relatively short period. Secondly, the precision of the roll forming process results in consistent quality and reduced need for post-production adjustments. Additionally, these machines often feature automation capabilities, which further enhance production rates and reduce labor costs.

Conclusion

The Z shape roll forming purlin machine is an indispensable tool in the construction sector, contributing to the efficiency and effectiveness of building frameworks. Its ability to produce high-quality, lightweight purlins with minimal waste aligns perfectly with the industry's evolving demands for sustainable and economical construction solutions. As the market continues to grow, advancements in roll forming technology are expected to improve the performance and capabilities of these machines, making them even more valuable for manufacturers and builders alike. Whether for commercial, residential, or agricultural applications, Z shape purlins produced by these machines will undoubtedly remain a pivotal element in modern construction practices.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025