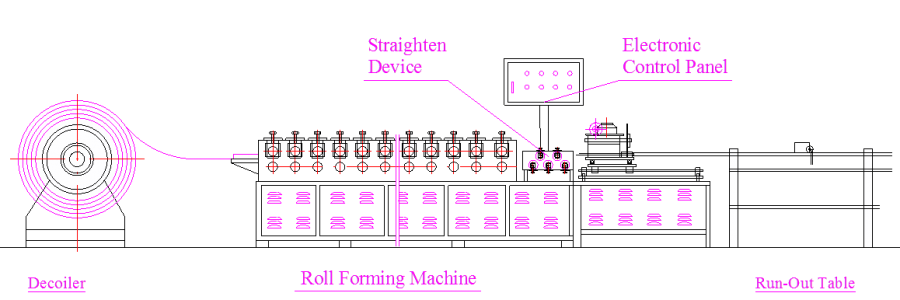

This wall stud roll forming machine produces multi-profiles and size-changing by the spacer. in fact, it is Multi size wall stud and tracks machine for multi-profiles,size-changing by the spacer. there is an Enlarged hydraulic station to ensure high-speed working. Easy operation, low maintenance cost.

Μηχανή διαμόρφωσης ρολού δαπέδου από χάλυβα