Ιαν . 20, 2025 16:43

Back to list

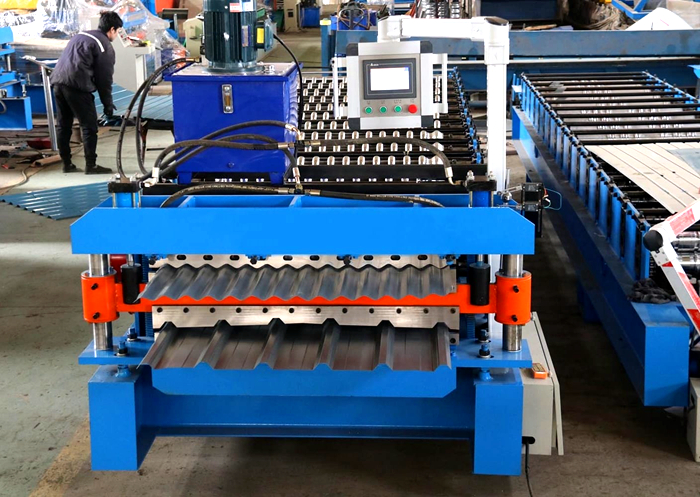

Maquina para PANEL TINGLADO , TINGLADO panel forming machine

Roll forming machines are integral to the manufacturing process of various industries, transforming metal sheets into desired profiles with precision and efficiency. Understanding the different types of roll forming machines can significantly impact production quality, efficiency, and cost-effectiveness. Here's a detailed examination of the various types of roll forming machines, based on industry expertise and technical authority.

Specialty roll forming machines are designed for peculiar profiles and intricate applications. These machines are engineered to cater to bespoke manufacturing requirements, including highly complex or custom-designed metal shapes. While they may demand higher initial investment and specialized operators, the precision and uniqueness of output they offer are unmatched. Industries focusing on niche manufacturing or those requiring intricate components, such as aerospace or specialized construction projects, frequently rely on these machines to meet specific production standards. Selection of the appropriate roll forming machine derives from a nuanced understanding of production requirements, material specifications, and desired output characteristics. Expertise in roll forming technology is crucial to ensuring optimal machine selection and configuration. Experienced technicians often leverage their understanding of material properties, such as tensile strength and malleability, to calibrate machines for optimal performance. Furthermore, authoritative knowledge in machine operation, material handling, and maintenance substantially adds to the reliability and longevity of roll forming machines. Trust in roll forming technology is built upon decades of industrial use and continued advancements in mechanical engineering. Leading manufacturers adhere to rigorous quality controls, often incorporating advanced technology such as CNC controls for enhanced precision and automation capabilities. Trustworthiness is not only reflected in the machine’s performance but also in the after-sales services and technical support provided, ensuring an unwavering production process. In conclusion, selecting the right type of roll forming machine involves balancing your specific manufacturing needs with machine capabilities. It's about enhancing production efficiency while ensuring quality and precision. By leveraging an understanding of each machine type, their unique strengths, and their application contexts, manufacturers can significantly improve their operational success and maintain a competitive edge in the industry.

Specialty roll forming machines are designed for peculiar profiles and intricate applications. These machines are engineered to cater to bespoke manufacturing requirements, including highly complex or custom-designed metal shapes. While they may demand higher initial investment and specialized operators, the precision and uniqueness of output they offer are unmatched. Industries focusing on niche manufacturing or those requiring intricate components, such as aerospace or specialized construction projects, frequently rely on these machines to meet specific production standards. Selection of the appropriate roll forming machine derives from a nuanced understanding of production requirements, material specifications, and desired output characteristics. Expertise in roll forming technology is crucial to ensuring optimal machine selection and configuration. Experienced technicians often leverage their understanding of material properties, such as tensile strength and malleability, to calibrate machines for optimal performance. Furthermore, authoritative knowledge in machine operation, material handling, and maintenance substantially adds to the reliability and longevity of roll forming machines. Trust in roll forming technology is built upon decades of industrial use and continued advancements in mechanical engineering. Leading manufacturers adhere to rigorous quality controls, often incorporating advanced technology such as CNC controls for enhanced precision and automation capabilities. Trustworthiness is not only reflected in the machine’s performance but also in the after-sales services and technical support provided, ensuring an unwavering production process. In conclusion, selecting the right type of roll forming machine involves balancing your specific manufacturing needs with machine capabilities. It's about enhancing production efficiency while ensuring quality and precision. By leveraging an understanding of each machine type, their unique strengths, and their application contexts, manufacturers can significantly improve their operational success and maintain a competitive edge in the industry.

Latest news

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

Related Products