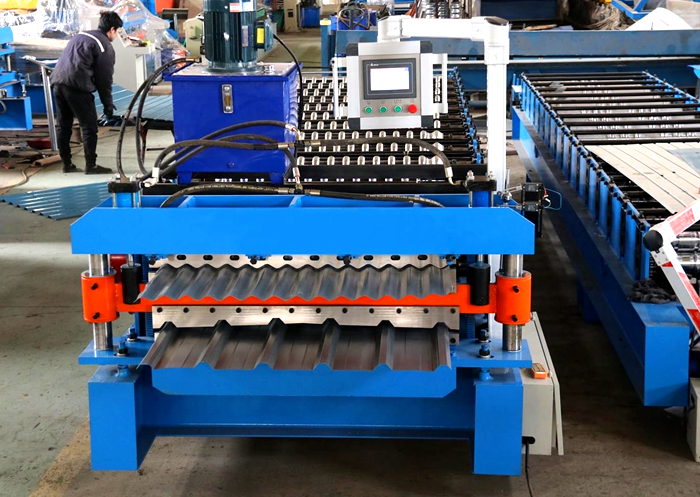

roll forming machine factory company

The Rise of Roll Forming Machine Factories in Modern Manufacturing

The evolution of manufacturing technology has brought forth innovative solutions to meet the increasing demands for precision and efficiency. Among these advancements, roll forming machines have emerged as a pivotal component in the production of metal components across various industries. The growth of roll forming machine factories not only signifies technological progress but also illustrates the shift towards automated and scalable manufacturing processes.

Roll forming is a continuous bending operation in which a long strip of metal is passed through consecutive rolls to shape it into desired profiles. This process is renowned for its ability to produce complex shapes while maintaining high uniformity and minimizing waste. This is particularly important in industries such as construction, automotive, and aerospace, where the integrity and precision of metal components are critical.

The Rise of Roll Forming Machine Factories in Modern Manufacturing

One of the key advantages of roll forming is its capability for high-volume production. Unlike traditional machining processes that can be time-consuming and costly, roll forming allows for the efficient manufacture of large quantities of metal components. This efficiency not only reduces production costs but also shortens lead times, enabling companies to respond more swiftly to market demands.

roll forming machine factory company

The roll forming machine factory demonstrates a blend of automation and craftsmanship. Modern factories utilize Computer Numerical Control (CNC) technology to ensure precision in each stage of the manufacturing process. This level of automation minimizes human error and enhances the repeatability of the production process, ultimately leading to higher quality products. Furthermore, advancements in materials science and engineering have allowed for the development of stronger and lighter materials, which can be used in conjunction with roll forming technology.

In addition to technological advancements, there is a growing emphasis on environmental sustainability within roll forming machine factories. Many manufacturers are adopting green practices by reducing energy consumption and waste during production. The utilization of renewable energy sources and recycling programs has become increasingly common, reflecting a collective effort within the industry to minimize its ecological footprint.

Another noteworthy trend within the industry is the move toward globalization. Roll forming machine factories are not only catering to domestic demands but are also exporting their products internationally. This globalization creates opportunities for collaboration and knowledge exchange, further driving innovation in the field. The exchange of ideas and technologies among factories around the world fosters competition and encourages continuous improvement.

In conclusion, the growth of roll forming machine factories represents a significant trend in modern manufacturing. As industries continue to evolve and demand greater efficiency and precision, roll forming machines will play an increasingly important role. The combination of advanced technology, skilled labor, and a focus on sustainability positions roll forming machine factories at the forefront of the manufacturing revolution. As these factories expand and innovate, they hold the promise of shaping a more efficient and sustainable future for the manufacturing industry, making them indispensable players in the economic landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025