Φεβ . 10, 2025 09:58

Back to list

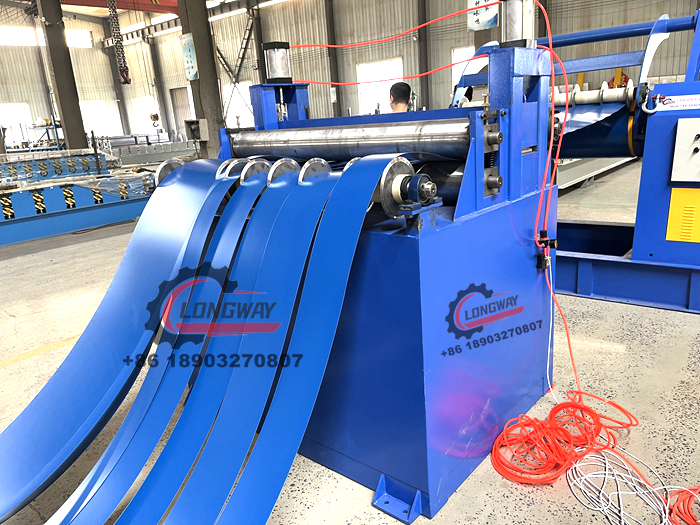

cladding roll forming machine

In the dynamic world of construction and architecture, the pivotal role of a purlin roll forming machine manufacturer cannot be overstated. As the backbone of innovative structural solutions, these machines are responsible for forming metal purlins — critical components that enhance the structural integrity of modern buildings. The essence of choosing the right manufacturer extends beyond acquiring machinery; it involves a commitment to quality, expertise, and trustworthiness in building enduring infrastructures.

Authoritativeness in the industry is a mark of distinction for top purlin roll forming machine manufacturers. These manufacturers often participate in and contribute to industry standards bodies and regularly update their products to comply with the latest regulations. Their commitment to industry leadership is evident in their active engagement in research and development, often resulting in pioneering technologies that set benchmarks for quality and performance. Manufacturers recognized as authorities in the field leverage their reputation to foster partnerships with key stakeholders, including suppliers, construction companies, and regulatory bodies. Trustworthiness is perhaps the most vital attribute, encompassing reliability, integrity, and customer satisfaction. Trustworthy manufacturers are transparent about their production processes and materials, providing certifications that authenticate the quality and durability of their machines. They are also proactive in after-sales service, ensuring swift response times and availability of spare parts which minimizes downtime for customers. By building a solid track record of reliable service and dependability, these manufacturers cultivate long-term relationships with customers who return time and again for their durability and efficiency needs. In conclusion, selecting a purlin roll forming machine manufacturer is a decision that impacts the very core of construction efficiency and success. The right manufacturer is an amalgamation of rich experience, expert solutions, authoritative command of the industry, and a trustworthy approach to business. As construction technology continues to advance, these manufacturers play a crucial role in shaping the future of how structures are built, ensuring durability and safety are paramount. Prospective buyers must, therefore, conduct due diligence, choosing partners who will contribute enduring value to their enterprises and the industry at large.

Authoritativeness in the industry is a mark of distinction for top purlin roll forming machine manufacturers. These manufacturers often participate in and contribute to industry standards bodies and regularly update their products to comply with the latest regulations. Their commitment to industry leadership is evident in their active engagement in research and development, often resulting in pioneering technologies that set benchmarks for quality and performance. Manufacturers recognized as authorities in the field leverage their reputation to foster partnerships with key stakeholders, including suppliers, construction companies, and regulatory bodies. Trustworthiness is perhaps the most vital attribute, encompassing reliability, integrity, and customer satisfaction. Trustworthy manufacturers are transparent about their production processes and materials, providing certifications that authenticate the quality and durability of their machines. They are also proactive in after-sales service, ensuring swift response times and availability of spare parts which minimizes downtime for customers. By building a solid track record of reliable service and dependability, these manufacturers cultivate long-term relationships with customers who return time and again for their durability and efficiency needs. In conclusion, selecting a purlin roll forming machine manufacturer is a decision that impacts the very core of construction efficiency and success. The right manufacturer is an amalgamation of rich experience, expert solutions, authoritative command of the industry, and a trustworthy approach to business. As construction technology continues to advance, these manufacturers play a crucial role in shaping the future of how structures are built, ensuring durability and safety are paramount. Prospective buyers must, therefore, conduct due diligence, choosing partners who will contribute enduring value to their enterprises and the industry at large.

Latest news

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

Related Products