High-Quality Profile Roll Forming Machine Supplier | Custom Solutions

Understanding the Role of Profile Roll Forming Machine Suppliers

In today’s manufacturing landscape, the need for efficient and precise production processes is paramount. One of the key technologies in this domain is the profile roll forming machine. These machines are crucial for producing a wide array of metal profiles that are essential in construction, automotive, appliances, and various other industries. As a result, choosing the right profile roll forming machine supplier becomes a critical decision for manufacturers seeking to enhance their operational efficiency.

Profile roll forming machines work by converting flat metal sheets into specific shapes through a series of rollers. This process offers several advantages, including high precision, consistent quality, and the ability to work with various materials. However, the effectiveness of this technology is heavily dependent on the supplier's capabilities. A reliable supplier not only provides quality machinery but also offers technical support, training, and maintenance services that are vital for seamless operations.

When selecting a supplier, manufacturers need to consider several factors. Firstly, the supplier’s experience in the industry is crucial. An established company with a proven track record is more likely to understand the unique needs of different sectors and provide tailored solutions. Furthermore, the supplier's ability to innovate and integrate the latest technologies can significantly impact production efficiency. Suppliers that invest in research and development are better positioned to offer advanced machines that enhance productivity and reduce downtime.

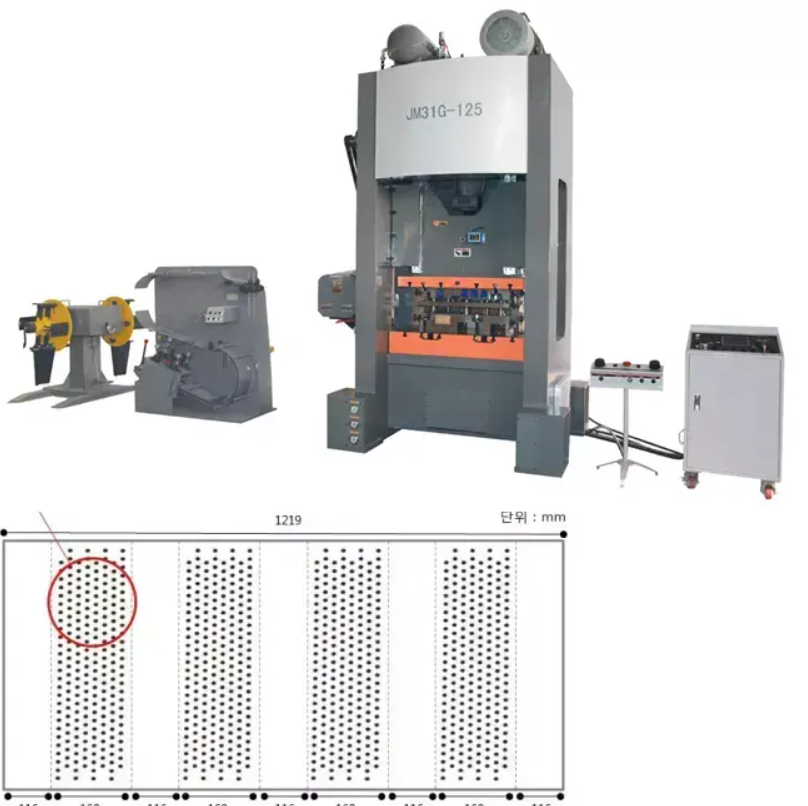

profile roll forming machine supplier

Additionally, customer support is a key aspect to evaluate. A reliable supplier should offer comprehensive after-sales support, including installation, troubleshooting, and regular maintenance services. This support can prevent significant losses due to machine malfunctions, ensuring that production processes remain uninterrupted. Testimonials and case studies from other clients can provide insight into the supplier’s reliability and service quality.

Cost is another important consideration. While it is tempting to go for the cheapest option, it’s essential to weigh price against quality and support. Investing in a more expensive but reliable machine from a reputable supplier may lead to lower long-term operational costs.

Moreover, sustainability is becoming increasingly important in manufacturing. Suppliers that prioritize environmentally friendly practices, such as energy-efficient machines and eco-friendly materials, can help manufacturers align with global sustainability goals. Sustainable practices not only enhance a company's reputation but can also lead to cost savings in the long run.

In conclusion, the role of profile roll forming machine suppliers is vital for manufacturers aiming to streamline their production processes. By focusing on experience, technology, customer support, cost, and sustainability, manufacturers can choose the right supplier that meets their needs and drives operational excellence. Ultimately, a good supplier partnership can be a game-changer in achieving manufacturing success.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025