Portable Standing Seam Roll Formers from Top Manufacturing Facilities Worldwide

Understanding Portable Standing Seam Roll Former Factories

In the realm of metal fabrication, the standing seam roof system has emerged as a popular choice for its durability, aesthetic appeal, and energy efficiency. At the heart of this manufacturing process lies the portable standing seam roll former—a machine designed to create robust metal panels for roofing systems. With the rising demand for such roofing solutions, understanding portable standing seam roll former factories and their role in the industry has become increasingly important.

What is a Portable Standing Seam Roll Former?

A portable standing seam roll former is a specialized piece of equipment used to manufacture metal roofing panels that feature a raised seam design. This design allows for expansion and contraction due to temperature changes, making it an ideal choice for regions with extreme weather conditions. The roll forming process involves passing a continuous strip of metal through a series of rollers that shape the material into the final profile.

The portability of these machines is a significant advantage. Traditional roll forming equipment is often fixed in place, requiring considerable space and infrastructure. In contrast, portable roll formers can be transported to various job sites, allowing for on-site production and eliminating the need for transporting large panels. This capability not only reduces transportation costs but also minimizes waste by allowing for precise cutting at the installation site.

The Manufacturing Process in Roll Former Factories

In portable standing seam roll former factories, the manufacturing process begins with high-quality metal coils, typically made from materials like steel or aluminum. These coils are unwound and fed into the roll former, where engineers carefully adjust the settings to match the desired panel specifications. The roll formers are equipped with advanced technology, allowing for quick changeovers when producing different profiles or sheet lengths.

As the metal passes through the rollers, it is slowly shaped into the standing seam profile. The process is continuous and can produce long lengths of material. Once the panels are formed, they are cut to specified lengths, and additional processes such as punching or notching may be performed to create necessary features for attachment and sealing.

Innovation and Technology in Roll Forming

The portable standing seam roll former industry has benefited from advancements in technology. Modern roll forming machines often feature digital controls, allowing operators to program and monitor the production process with precision. This automation leads to increased efficiency and reduces the likelihood of human error.

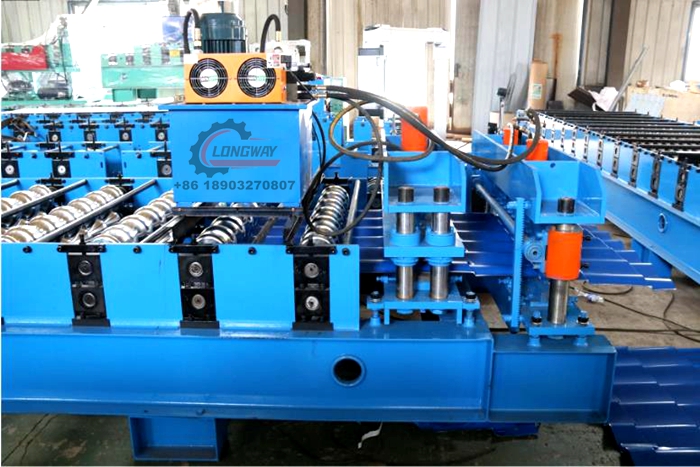

portable standing seam roll former factories

Additionally, many factories incorporate computer-aided design (CAD) software to streamline the design process for custom panel shapes. This technological integration enables quicker responses to market demands, as manufacturers can adapt to unique architectural requirements or changes in consumer preferences.

Benefits of Portable Standing Seam Roll Former Factories

1. Increased Efficiency The ability to produce panels on-site reduces turnaround time and labor costs. Contractors can install roofing immediately after manufacturing, leading to faster project completion.

2. Quality Control By manufacturing panels on-site, companies can maintain strict quality control. Any imperfections can be addressed immediately, ensuring that only high-quality materials are used in construction.

3. Flexibility Portable roll forming machines can produce various profiles and materials, allowing manufacturers to cater to diverse customer needs. This flexibility is essential in a competitive market where customization is increasingly valued.

4. Sustainability On-site production helps minimize waste and is often more environmentally friendly, as it reduces the carbon footprint associated with transporting materials. Using local resources also supports sustainable practices within the industry.

Conclusion

Portable standing seam roll former factories play an essential role in modern metal roofing production. By leveraging advanced technology and manufacturing processes, these facilities are able to meet the growing demand for standing seam roofing systems. Their portability offers unparalleled flexibility and efficiency, making them an attractive option for contractors and builders across the globe.

In summary, understanding the significance and operation of portable standing seam roll former factories provides valuable insights into the future of roofing solutions. As the industry continues to evolve, these factories are poised to lead the way in producing high-quality, durable, and aesthetically pleasing roof systems that meet the needs of both consumers and contractors alike.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025