metal stud roll forming machine for sale companies

Exploring the Metal Stud Roll Forming Machine Market

In the ever-evolving world of construction and architecture, efficiency and precision in material production are paramount. One of the crucial components in modern building structures is the metal stud, which serves as an integral element for framing. As a result, the demand for high-quality Metal Stud Roll Forming Machines has surged, with numerous companies entering the marketplace to meet this demand. This article delves into the significance of these machines, the technology behind them, and the current landscape of companies offering these products.

Understanding Metal Stud Roll Forming Machines

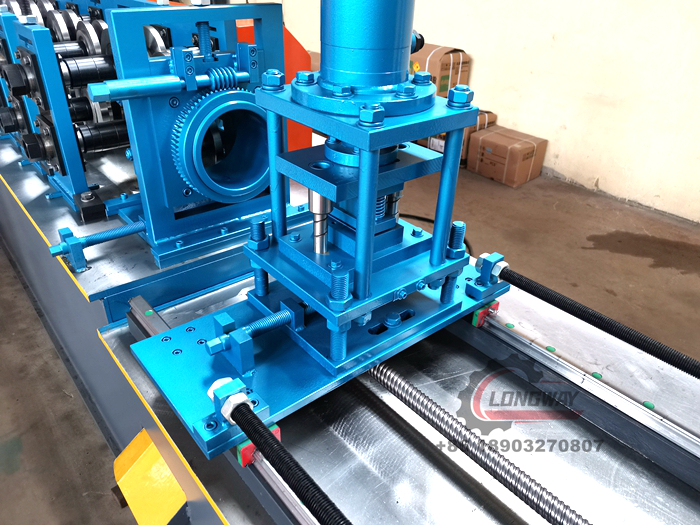

Metal stud roll forming machines are specialized equipment designed to create metal studs used in drywall and steel framing applications. The process involves feeding a metal coil into the machine, where it undergoes a series of forming operations to become the desired shape, size, and strength. The advantages of using metal studs over traditional wooden studs include enhanced durability, resistance to pests, fire safety, and consistent quality. As the construction industry increasingly opts for lightweight and durable materials, the role of roll forming machines becomes more critical.

Innovations in Roll Forming Technology

The technological advancements in roll forming machines have greatly improved the efficiency and accuracy of metal stud production. Modern machines are equipped with advanced features such as computerized controls, which allow for precise adjustments to the forming process. They also offer the ability to produce various sizes and profiles of metal studs, accommodating different construction requirements. Additionally, many manufacturers now include automated feeding systems, reducing labor costs and increasing production speed.

Some of the latest machines incorporate multi-functional capabilities, enabling operators to produce not just metal studs, but a range of related components such as tracks and connectors. This flexibility provides significant cost savings for companies looking to optimize their operations.

Leading Companies in the Market

As the demand for metal stud roll forming machines grows, numerous companies have emerged as key players in the industry

. Here are a few notable manufacturers known for their innovative machines and solutionsmetal stud roll forming machine for sale companies

1. SAMCO Machinery - Known for its robust and versatile roll forming machines, SAMCO offers a range of lines capable of producing metal studs and track systems. Their customizable solutions cater to different scales of production, making them a favored choice among contractors and builders.

2. Formtek - A trusted name in the forming industry, Formtek designs machines that focus on precision and efficiency. Their range of roll forming machines covers various applications, including the production of metal studs, and they offer excellent customer support and training.

3. Cangzhou Golden Elephant - Based in China, Golden Elephant specializes in manufacturing high-quality roll forming machines at competitive prices. They provide customized solutions to meet diverse production needs, making them popular among international clients.

4. Pioneer Machinery - Known for its user-friendly machines, Pioneer Machinery focuses on providing affordable solutions for contractors. Their machines are designed for easy operation and maintenance, appealing to smaller businesses and startups.

The Future of Metal Stud Roll Forming Machines

The future of metal stud roll forming machines appears promising, with ongoing innovations expected to enhance production capabilities further. The growing focus on sustainable construction practices also points towards an increased use of metal studs, which align with environmentally-friendly building practices. Additionally, as smart manufacturing technologies continue to develop, incorporating IoT and AI into roll forming processes could lead to further efficiency gains.

Conclusion

In summary, the metal stud roll forming machine market is flourishing, driven by the ever-increasing demand for efficient, durable, and cost-effective construction materials. As companies evolve and expand their offerings to meet diverse construction needs, the role of advanced roll forming technology will only become more significant. Organizations looking to invest in this equipment should consider not only the quality and performance of the machines but also the reputation and support offered by the manufacturer. The right machine can greatly enhance productivity and ensure successful outcomes in construction projects.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025