Versatile Machine for Custom Pressing of Corrugated Sheets in Various Sizes and Designs

Custom Corrugated Sheet Pressing Machine Revolutionizing Sheet Production

In today's fast-paced manufacturing landscape, efficiency and innovation are paramount. Among the numerous machines that facilitate these goals, the custom corrugated sheet pressing machine stands out as an essential tool for industries ranging from packaging to construction. This specialized machine is designed to enhance the production of corrugated sheets, which are crucial for creating sturdy packaging materials, insulation, and various structural components.

Understanding Corrugated Sheets

Corrugated sheets are made from a fluted sheet of paper sandwiched between two linerboards. This design provides exceptional strength-to-weight ratio, making them ideal for packaging applications. The pressing machine is responsible for efficiently creating the corrugated wave pattern that gives these sheets their unique properties. By compressing layers of paper at high pressures, the machine ensures uniformity and structural integrity, essential for maintaining quality in high-volume production.

Features of Custom Corrugated Sheet Pressing Machines

A custom corrugated sheet pressing machine offers a range of features tailored to meet the specific needs of manufacturers. Advanced models come equipped with programmable logic controllers (PLCs), allowing operators to adjust pressure settings, speed, and other parameters with precision. This customization is crucial for optimizing production efficiency and ensuring consistent output quality.

Moreover, many modern machines incorporate automation technology, reducing labor costs and minimizing human error. Automated feeding systems can handle raw materials and finished products, streamlining the workflow and enhancing overall productivity. Additionally, technologies like servo motors provide faster response times and improved energy efficiency, making these machines not only effective but also environmentally friendly.

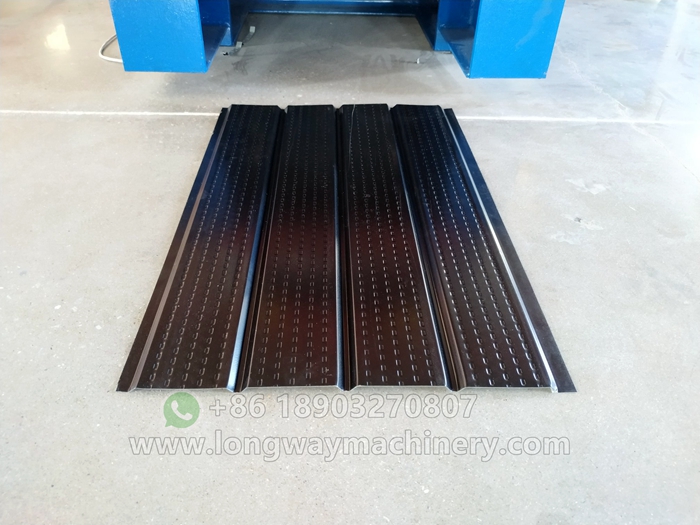

custom corrugated sheet pressing machine

Benefits of Using Custom Pressing Machines

1. Tailored Production One of the most significant advantages of custom corrugated sheet pressing machines is their ability to be tailored to specific production requirements. Manufacturers can request modifications based on the size, thickness, and type of corrugated sheets they need, ensuring that the machine aligns perfectly with their operational goals.

2. Increased Efficiency The advanced technology integrated into these machines greatly enhances production efficiency. By reducing cycle times and optimizing material usage, manufacturers can produce larger quantities of corrugated sheets without sacrificing quality. This increased efficiency translates into higher profitability and a competitive edge in the market.

3. Durability and Reliability Custom machines are built to withstand the rigorous demands of high-volume production. Using high-quality materials and robust engineering designs, these machines offer long-term reliability, reducing maintenance costs and downtime. Manufacturers can focus on production without the constant worry of equipment failure.

4. Sustainability As industries become more environmentally conscious, the need for sustainable manufacturing processes has risen. Custom corrugated sheet pressing machines can be designed to utilize recycled materials effectively, reducing waste and promoting eco-friendly production methods.

Conclusion

The custom corrugated sheet pressing machine is a pivotal development in the realm of manufacturing. Its ability to produce high-quality corrugated sheets efficiently and sustainably caters to the diverse needs of various industries. As technology continues to evolve, these machines will undoubtedly incorporate even more advanced features, further enhancing their performance and utility. Manufacturers looking to stay ahead in a competitive market should consider investing in these cutting-edge machines to streamline production, reduce costs, and meet growing demand for quality corrugated products. By doing so, they not only improve their operations but also contribute to a more sustainable manufacturing process.

-

Understanding Steel Coil Cutting Machines and Their ImportanceNewsMay.16, 2025

-

The Essential Guide to Floor Deck Roll Forming MachinesNewsMay.16, 2025

-

Slitting Lines and Their BenefitsNewsMay.16, 2025

-

Sheet Metal Slitting Machines and Their OptionsNewsMay.16, 2025

-

Choosing the Best Downpipe Roll Forming MachinesNewsMay.16, 2025

-

5 Inch Gutter Machines: The Key to Efficient Gutter ProductionNewsMay.16, 2025

-

The Latest Trends in Cut to Length Equipment and MachinesNewsMay.09, 2025