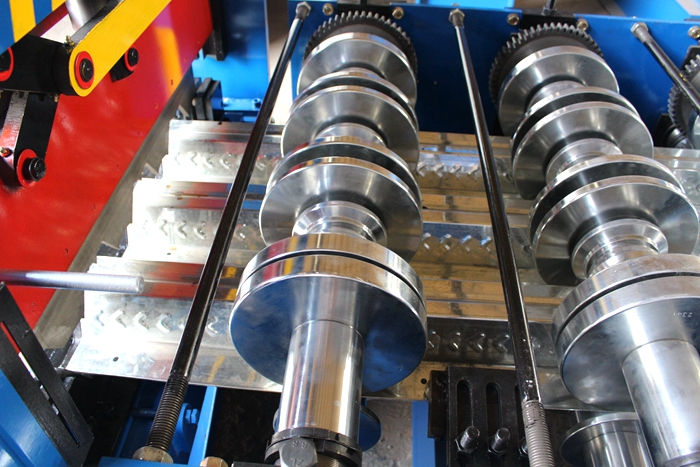

soffit panel machine

Understanding Soffit Panel Machines A Key in Construction

Soffit panels play a crucial role in both the aesthetic and functional aspects of construction, particularly in roofing systems. These panels are typically installed beneath the eaves of a roof, providing ventilation and an appealing finish that enhances the building's exterior. To meet the growing demand for soffit panels in the building industry, manufacturers have developed specialized machines, known as soffit panel machines. This article will explore the significance and functioning of these machines in modern construction.

Soffit panel machines are designed to produce various types of soffit panels efficiently and accurately. These machines can create panels from different materials, including aluminum, vinyl, and fiber cement, each offering unique advantages. For instance, aluminum soffit panels are corrosion-resistant and lightweight, making them ideal for long-lasting installations. Conversely, vinyl panels are favored for their low maintenance and cost-effectiveness.

The operation of a soffit panel machine involves several crucial steps. Initially, raw materials are fed into the machine, where they are cut and shaped according to specific dimensions and designs. The machine uses advanced technology, including computer numerical control (CNC), to ensure precision in manufacturing. This level of accuracy is critical in maintaining the quality and consistency of the panels, which ultimately impacts installation processes and durability.

soffit panel machine

Moreover, soffit panel machines are equipped with features that enhance production efficiency. Automated systems minimize manual intervention, reducing labor costs and increasing output. Many machines also have capabilities for producing customized designs, allowing builders to meet the unique requirements of different projects. This flexibility is essential in today's construction landscape, where personalization is increasingly in demand.

The importance of soffit panels extends beyond aesthetics; they also contribute to the structural integrity and ventilation of buildings. Proper ventilation is essential for preventing moisture buildup, which can lead to mold growth and structural damage over time. Consequently, utilizing well-manufactured soffit panels is vital for the longevity of any construction.

In conclusion, soffit panel machines represent a significant advancement in the production of building materials, allowing for high-quality, customizable options for contractors and builders. As the construction industry continues to evolve, these machines will play an increasingly important role in meeting the needs of modern architecture, ensuring that properties are not only beautiful but also durable and functional. Understanding the effectiveness and capabilities of soffit panel machines is essential for anyone involved in construction, offering insights into their integral role in shaping the future of building practices.

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025