metal roofing roll former for sale factories

Exploring Metal Roofing Roll Formers for Sale

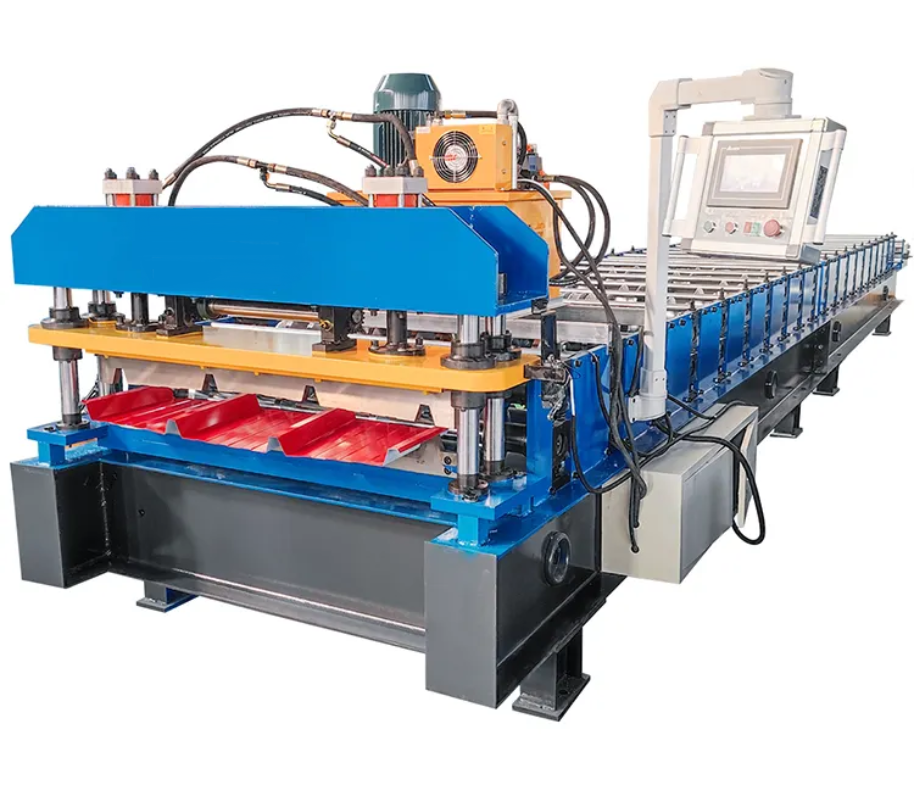

In the ever-evolving construction industry, metal roofing has gained immense popularity due to its durability, efficiency, and aesthetic appeal. As these trends grow, the demand for specialized equipment like metal roofing roll formers has surged. These machines are integral in producing high-quality metal roofing sheets, catering to both commercial and residential needs. In this article, we will explore what metal roofing roll formers are, their significance in the roofing industry, and how to choose the right one for your needs.

What is a Metal Roofing Roll Former?

A metal roofing roll former is a machine used to manufacture metal roofing materials in a continuous process. It transforms metal coils into various profiles and shapes, which are then used in roofing applications. The machine operates by feeding the metal coil through a series of rollers that gradually transform the flat material into the desired profile. This process allows for precise and efficient production, reducing both waste and labor costs.

The Significance of Metal Roofing Roll Formers

1. Efficiency and Speed One of the primary advantages of using a roll former is the speed at which materials can be produced. Unlike traditional methods of roofing installation, which can be time-consuming, roll formers can produce large quantities of roofing sheets in a short period. This efficiency is crucial for construction projects that demand quick turnaround times.

2. Customization Roll formers can be adjusted to produce a variety of profiles, such as standing seam, corrugated sheets, and more. This versatility allows manufacturers to cater to a wide range of design requirements and preferences, helping to meet specific client needs.

3. Material Waste Reduction With the precision of roll forming technology, companies can minimize material waste. This is not only environmentally friendly, but it also translates to cost savings for manufacturers and clients alike.

4. Consistency and Quality High-quality roll formers produce consistent and uniform roofing sheets, ensuring that products meet industry standards. This consistency is essential for achieving structural integrity and aesthetic appeal in roofing installations.

metal roofing roll former for sale factories

Choosing the Right Metal Roofing Roll Former

When considering the purchase of a metal roofing roll former, several factors need to be taken into account

1. Production Capacity Assess the volume of roofing sheets you need to produce. Different machines have varying operational speeds and capacities, so choosing one that aligns with your production goals is vital.

2. Flexibility Select a roll former that can produce versatile profiles. This feature will allow you to cater to a wider range of client demands without needing multiple machines.

3. Build Quality The durability of the roll former is crucial. Look for machines made from high-quality materials that can withstand the rigors of constant operation.

4. Technical Support and Warranty A reliable manufacturer will provide solid technical support and warranty services. This support is essential for minimizing downtime in case of machine failures.

5. Budget Finally, consider your budget. While it's important to invest in a high-quality machine, ensure that it aligns with your financial capabilities. Look for balance between cost, quality, and features.

Conclusion

In conclusion, investing in a metal roofing roll former can open up numerous opportunities for businesses in the roofing industry. The efficiency, customization, and quality offered by these machines make them a valuable asset for manufacturers aiming to meet the growing demand for metal roofing solutions. By carefully considering production capacity, flexibility, build quality, support, and budget, buyers can select the right roll former to elevate their operations and ensure success in this competitive market. As the roofing industry continues to grow, the importance of reliable and efficient production methods will only increase, making roll formers a cornerstone of modern roofing manufacturing.

-

The Role of Hydraulic Systems in Sheet Metal SlittersNewsAug.23, 2025

-

Customization Options in Metal Deck Roll Forming MachinesNewsAug.23, 2025

-

Safety Tips When Using a Gutter Making MachineNewsAug.23, 2025

-

Key Components of a C Purlin Machine ExplainedNewsAug.23, 2025

-

Maintenance Tips for a Steel Angle Roll Forming MachineNewsAug.23, 2025

-

Portable Metal Roofing Machine Applications in Remote ConstructionNewsAug.23, 2025

-

Roof Panel MachineNewsAug.18, 2025